Scientists from the University of Sheffield and Imperial College London worked in collaboration to create a new family of materials called meta-crystals.

“This approach to materials development has potentially far-reaching implications for the additive manufacturing sector,” explained Iain Todd, a professor at the University of Sheffield who was involved in the work, in a press release.

The advancement, which fused products made of metal with materials engineered to have special properties, will allow engineers to create more damage-tolerant materials, said Todd. It will also enable these engineered materials to better handle external loads, he added.

Along with Todd, Chen Liu and Jedsada Lertthanasarn also authored the research, which Nature, a science journal, published this month. Minh-Son Pham directed the research.

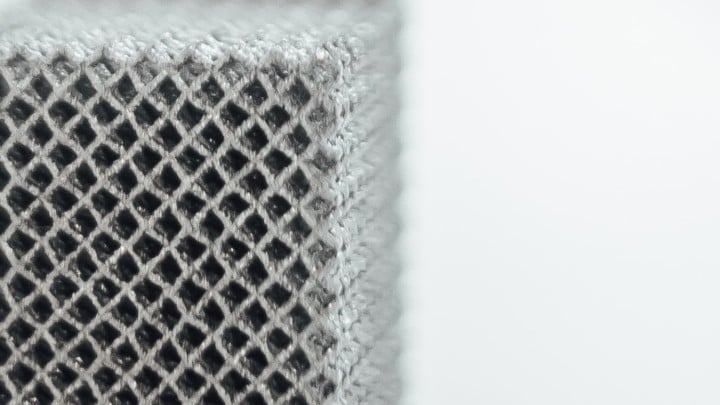

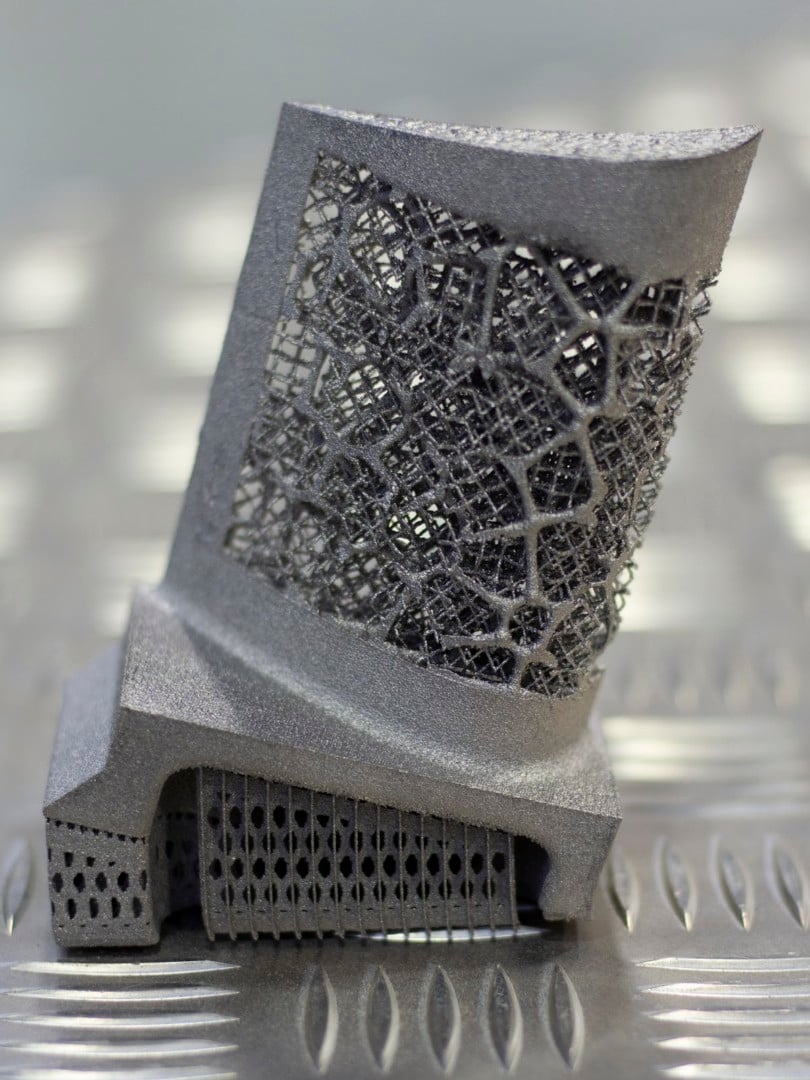

To develop meta-crystals, the scientists used built in a lattice, or grid structure, to mimic the polycrystalline structures of metals.

The resulting engineered materials can create 3D prints which are more lightweight, stronger and more robust than ever before.

Meta-Crystals are Stronger and Not Easily Damaged

Using lattice structures to boost strength and reduce weight is not a new concept in 3D printing. However, the scientists said, previous to their work, patterns regularly had a uniform layout.

In their paper, the scientists explained how uniform lattice layouts are inspired by a single metallic crystal. The uniform layout of the lattice structures usually has nodes all “conforming to a regular array.”

However, this uniformity means that when pressure is applied, the structure can permanently deform as the lattice breaks, causing a collapse.

Instead, materials with many crystals—called polycrystalline—have a random alignment of planes. This means that pressure on the structure can create a crack, but when that crack reaches a crystal where atoms are aligned differently, it will slow down or stop altogether.

The approach could be combined with advances in multi-material 3D printing, said Pham of Imperial College London.

It could be used in “developing new advanced materials that are lightweight and mechanically robust, with the potential to advance future low carbon technologies,” he added.

As well as developing engineered materials, the researchers are using them to study working with metal further. Learn more about this work by reading the paper Damage-tolerant architected materials inspired by crystal microstructure.

Check out more scientific advancements using 3D printing here:

MIT Scientists Reach Major Breakthrough with Glass 3D Printing Platform Scientists Print Artificial Coral to Rescue Great Barrier Reef Scientists Accidentally Create Mutant Enzyme that Eats PlasticSource: Press Release

License: The text of "Scientists Create Meta-crystals Using 3D Printing" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.