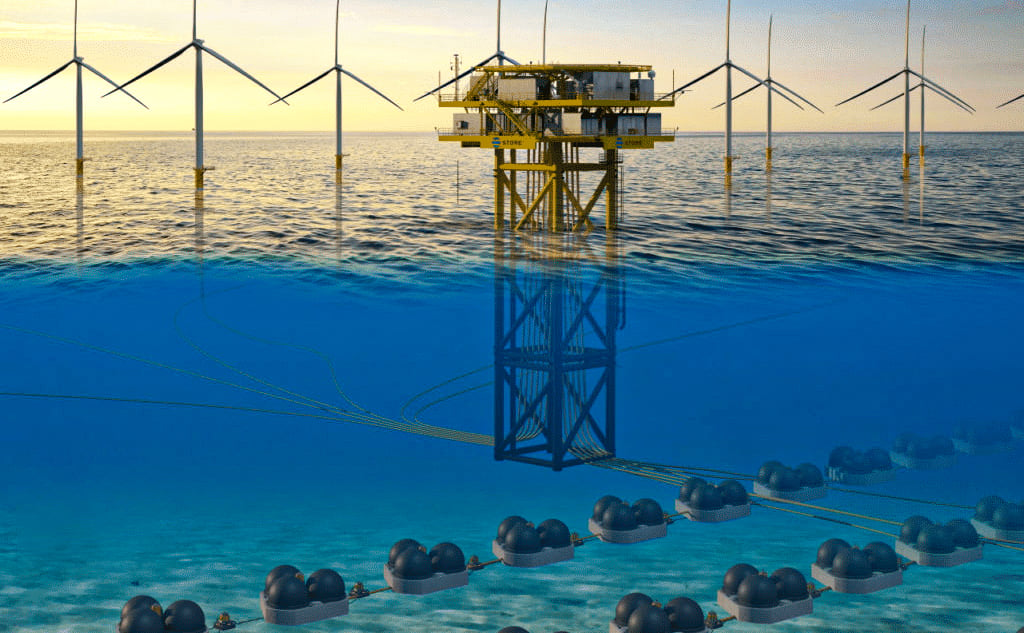

Sperra, formerly known as RCAM Technologies, just received a $4 Million grant from the US Department of Energy’s Water Power Technologies Office to 3D print concrete domes that will act as hydropower generators on the seabed off of Los Angeles, Calif. (The domes pictured above are one 30th the actual size.)

The energy project, which is still in the research stage, operates along coastlines or alongside offshore wind plants by moving water in and out of large concrete spheres on the ocean floor to store and release energy as needed. The total available marine energy resource in the United States is equivalent to approximately 57% of all US power generation, according to the US Department of Energy.

The German ministry of economic affairs and climate action is partnering on the project by providing an additional $3.7 million to support Fraunhofer IEE, the German research institute that has been working on this type of hydropower technology for several years.

Sperra, founded in 2017 by Jason Cotrell, an energy industry veteran, uses concrete 3D printers from CyBe Construction to construct not only these domes, but also elements of other energy projects, including bases for seabed-mounted wind turbines and anchors for floating renewable energy applications, along with land-based wind turbine towers and foundations.

Why 3D printed concrete and not traditional methods?

Sperra says its 3D printed concrete is “sustainable, locally sourced, non-toxic, low-carbon, and long-life,” yet details on its exact composition are not available. The 3D printing for the Subsea Pumped Hydroelectric Energy Storage project will be done ocean-side at the company’s 3D concrete printing research and development facility at the AltaSea facility at the Port of Los Angeles.

Sperra says its concrete products are designed to be manufactured cost-effectively and domestically using local labor and material supply chains, eliminating the need to import to meet the rapidly growing demand for renewable energy in the US. This is becoming a more common argument for all types of 3D printing applications.

“Automated manufacturing improves worker health and safety, slashes CAPEX, and increases production rates,” the company says.

Both Sperra and Fraunhofer say near-shore energy storage offers a sustainable energy solution that sidesteps many of the political and development constraints that hamper renewable energy projects on land, such as leasing land and community objections to unsightly towers or cables. Sperra also says ocean-floor solutions are “resilient to sea-level rise, fires, floods, freezing, droughts, and terrorism.”

“Pumped storage power plants are particularly suitable for storing electricity for several hours to a few days. However, their expansion potential is severely limited worldwide. Therefore, we are transferring their functional principle to the seabed – the natural and ecological restrictions are far lower there. In addition, the acceptance of the citizens is likely to be significantly higher,” explains Dr. Bernhard Ernst, senior project manager at Fraunhofer IEE in a press release.

All Sperra projects are still in development.

You May Also Like:

License: The text of "Start-Up Granted Millions to 3D Print Concrete Domes for the Ocean Floor" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.