In daily 3D printing operations, filament management is an essential task. Whether you’re running low on filament or changing colors or materials, effectively handling leftover filaments to avoid waste is a challenge every 3D printer user faces. Some choose to use scraps for small projects to minimize waste, while others opt for traditional methods like manual splicing, heat fusing, or chemical bonding – which, though somewhat effective, can be complex to operate and result in inconsistent outcomes.

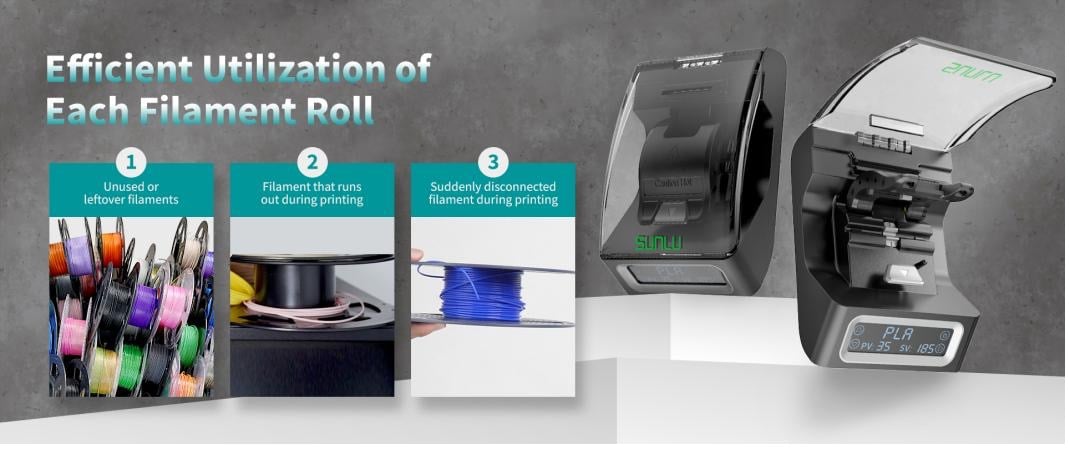

In contrast, a filament connector, with its efficiency and automation, becomes an ideal solution in 3D printing. It cleverly uses leftover filament, minimizes waste, and ensures high-quality splicing. To better serve 3D printing users, SUNLU launched the Filament Connector FC01 to celebrate its 11th anniversary. It offers perfect filament connections through automation and precise control, reducing waste and offering a more efficient and convenient solution for users.

Features and functions of SUNLU Filament Connector FC01

The SUNLU Filament Connector FC01 boasts several core advantages:

Zero waste

As mentioned above, leftover filament is often wasted in 3D printing. The SUNLU Filament Connector FC01 can reuse these leftovers, reducing unnecessary waste to help you be more environmentally friendly and cost-efficient. Every segment of filament can be fully utilized, making your 3D printing projects more efficient and economical.

Creative DIY

Easily splice different-colored filaments to add unlimited color possibilities to your 3D prints. Whether creating intricate multicolored models or gradient-effect artworks, the SUNLU Filament Connector FC01 makes it simple.

Precise temperature control

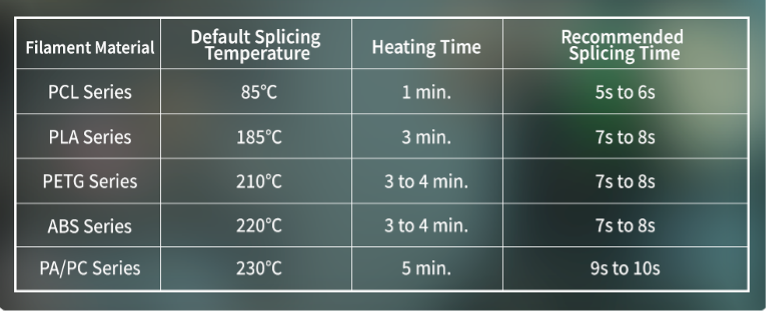

Under room-temperature conditions, the SUNLU Filament Connector FC01 takes only three minutes to quickly heat up to 185 ℃, significantly improving operational efficiency and reducing waiting time. The temperature displayed on the screen is strictly controlled to within ± 3 ℃ of the actual temperature, ensuring a precise and consistent splicing process.

Wide compatibility

Supporting temperatures up to 240 ℃, the SUNLU Filament Connector FC01 is compatible with various 3D printing filaments available on the market. The machine system comes with preset parameters for five common materials. For unlisted filaments, users can adjust settings according to their melting temperatures.

Safe design

Advanced temperature control technology combined with premium heat-insulating materials ensures that the external temperature range remains between 50-100 °C during splicing, allowing users to operate safely without worrying about burns.

Easy operation

With an intuitive interface design and detailed operation guides and video tutorials, even 3D printing beginners can quickly master the techniques. The splicing process is completed in 10–15 seconds, making the creative process smoother.

Visual operation

Built-in visual windows and a display screen provide real-time monitoring of the splicing process, ensuring every step is visible. The screen displays real-time temperature information, keeping users informed about the device’s working status.

High-quality splicing

Professional splicing technology ensures that the joint is strong and smooth, so it won’t affect printing results. Compared to interrupting printing, spliced filament produces models with seamless and smooth surfaces, maintaining a stable printing process and ensuring high-quality print outcomes.

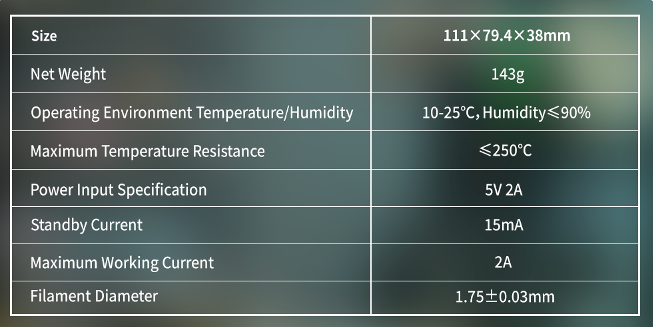

Product specifications

Message from SUNLU

When designing the SUNLU Filament Connector FC01, our goal was clear: to solve the common problem of filament waste in 3D printing and enhance users’ printing experience. We understand that for many creators, every segment of filament represents an investment of time and money. That’s why we focused on developing a practical and efficient tool that truly helps.

We hope that when you use the SUNLU Filament Connector FC01, you feel our dedication to product excellence and our deep understanding of users’ needs. We are committed to continuously optimizing our products, listening to your feedback, and exploring new possibilities. Thank you for choosing SUNLU, and we look forward to extending creativity together.