For most desktop 3D printers, increasing the print speed usually comes at a cost to quality. With low-cost 3D printers, there’s typically a limit to how fast you can create, and even when higher print speeds are achievable, the final result could be negatively impacted by the rushed operation. There are many factors that are impacted by print speed, including the stability of the machine and the ability for the filament to properly feed through the extrusion system.

As manufacturers continue to iterate and improve their technical expertise, some 3D printers allow for a print speed increase without sacrificing print quality. SUNLU, an established 3D printer brand known for its array of FDM materials, 3D printing pens, and its filament drying box, has entered the desktop 3D printer market with a machine they believe can out-speed any competitors in the same price range.

Its latest 3D printer, called the Terminator 3, is a wicked fast machine with several user-friendly features and functions. Let’s review some of the features of this high-speed, low-cost machine.

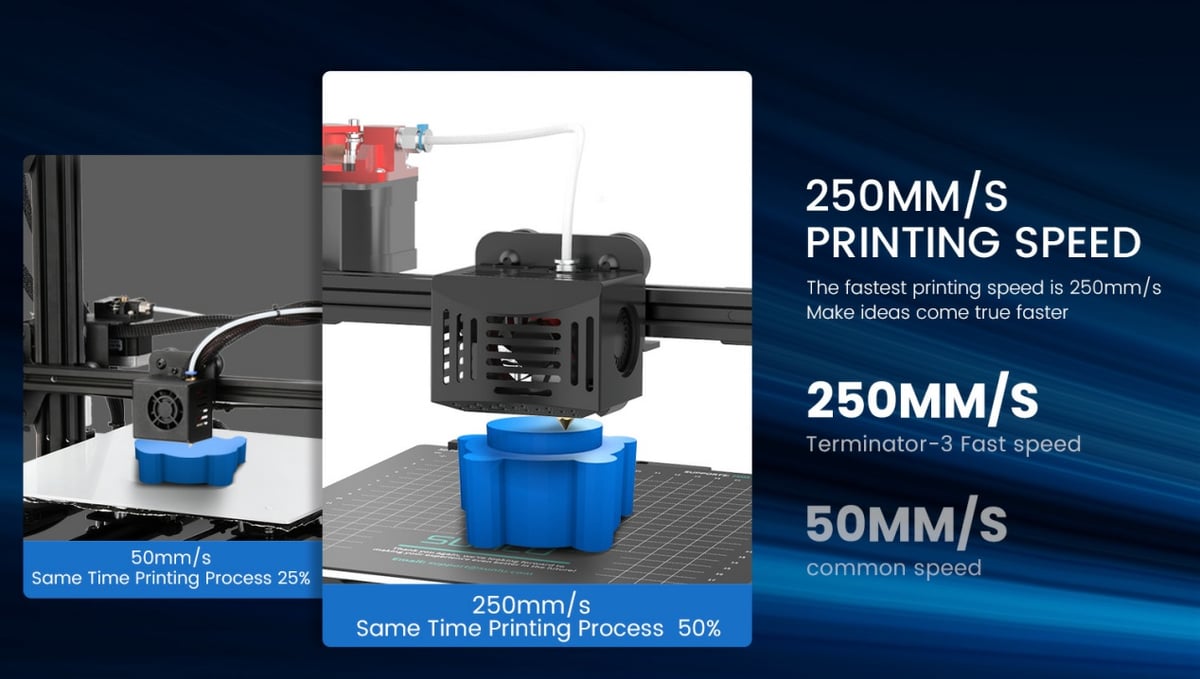

Market-Leading Print Speed of 250mm/s

The headline feature of the Terminator 3 is its printing speed of 250mm/s. While other leading 3D printers in its price range can operate with a print speed of 100mm/s, this machine is able to 2.5x that average speed without sacrificing print quality and accuracy.

How does the Terminator 3 manage to do it? Through a combination of a fast-printing algorithm, double gear extruder feeding, an intelligent temperature control system that involves multiple fans, as well as specially formulated fast printing filament. These three core dimensions of “software”, “hardware” and “consumables” ensure that printing quality and rapid print speed can be achieved simultaneously, maximizing the potential and output of the Terminator 3 model.

A Focus on Printer Success Rate

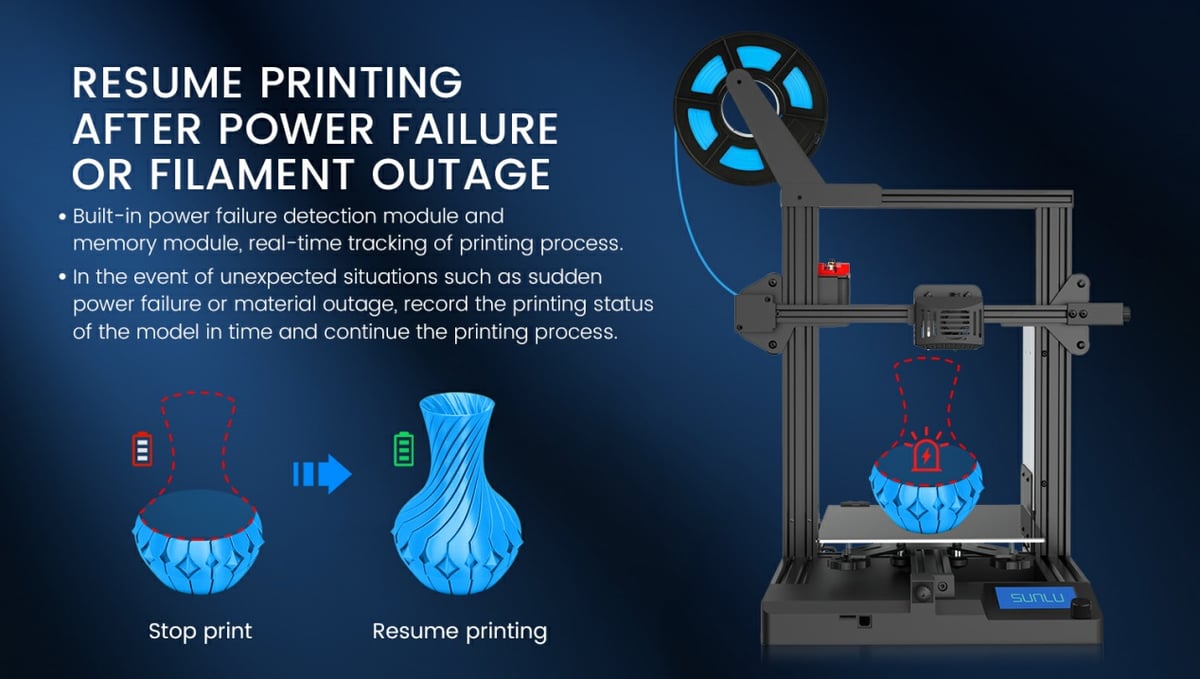

The Terminator 3 boasts an array of impressive features, including an advanced self-developed continued printing function. The 3D printer can pause operation and go into standby mode in the event of a nozzle blockage problem. After the nozzle is unclogged, the printing process is resumed exactly where it left off.

By avoiding nozzle blockage and print failure printing failure, SUNLU Terminator 3 reduces wasted resources and time – while directly improving the success rate.

Terminator 3 is also equipped with fully automated bed leveling, adding to its inherent ease of use. The printer’s X and Y-axis features a belt regulator that ensures accurate motion throughout the entire operation.

When it comes to printing success rate, the Terminator 3’s print resume functionality, automated bed leveling, emergency response, and machine life optimization put this 3D printer ahead of others in its price range.

Nearly Silent Operation

The T3 is equipped with a self-developed 32-bit high-performance silent motherboard and fully silent motor drive. During operation, the noise from the printer is as low as 45 decibels, creating a peaceful and quiet environment for home users.

Modular, All-Metal Design

The SUNLU Terminator 3 comes almost completely pre-assembled, requiring just three simple steps to get started on the printing journey. The grab-and-go handle attached to the top of the frame makes it surprisingly portable, meaning that the printer can be transported and used anywhere there’s a power outlet. The 400 x 400 x 470mm dimension frame is composed of solid metal, while the base of the machine is engineered to increase stability and durability. All in all, the Terminator 3 only weighs 7.25kg in total, lending itself to the portability of the machine.

High-Performance at a Low-Cost (+ Special Gifts)

The feature-packed Terminator 3 sells for $279, a low price you won’t find from most other brands in the market. On top of that, until October 31, 2022, SUNLU is gifting a whopping eight rolls of 250g filament with purchase of the Terminator 3 3D printer. If you’re interested in this bargain of a deal, you can visit SUNLU.COM for more details on the offer.

SUNLU: An Established Brand You Can Count On

SUNLU has become an established pioneer in the realm 3D printing materials and relevant products. The company was originally established in 2013 with just five employees, shipping 100,000 tons of FDM materials to customers around the world on an annual basis. In 2015, the annual number of shipments skyrocketed to two million tons, and in 2017, that number reached five million tons. Throughout the years, SUNLU has managed to safely deliver tons of PLA, ABS, TETG, TPU and other consumable products across the world. The company prides itself on producing a color assortment of filament with stable quality, creating a positive 3D printing experience for tens of millions of 3D printing lovers across the world.

In 2019, after years of accumulating more experience and establishing its technical expertise, SUNLU released its first FDM 3D printer: the S8. With its ultra-high performance and a large print volume, the printer was well-received by users in both North America and Europe.

In 2020, looking to link its foray into 3D printers with its long-held expertise in producing FDM consumables, SUNLU launched its first consumable drying oven: the S1. This unique piece of hardware accumulated over $300,000 in a crowdfunding campaign before officially launching on the global market. In the present day, with over 400 employees, the company has now delivered more than 20 million spools of filament, 4 million 3D printing pens and nearly 1 million consumable drying boxes to customers across the globe. While SUNLU has become an industry-leader in segments of the consumer 3D printing market, the release of the Terminator I3 looks to further expand its reach by offering customers a complete 3D printing ecosystem – from filament to the 3D printer.