Sunlu is an experienced 3D printing manufacturer, and their filament has always been prized by enthusiasts and experts alike. And, as 3D printing material masters, it’s not surprising the brand has developed a 3D printer that has a focus on improving the experience between machine and filament.

SUNLU has recently released the new S9 PLUS 3D printer, the industry’s first FDM machine with filament clog detection function and a fully integrated filament drying system. This new cost-effective printer offers an impressively large bed size of 310 x 310 x 400mm, automatic leveling, and other eye-catching functions. SUNLU is launching the S9 PLUS on Kickstarter, and campaign backers have the opportunity to get early bird pricing at just $259.

Let’s take a closer look at the SUNLU S9 PLUS and learn more about its groundbreaking features.

Clog Detection Brings Filament Monitoring to the Next Level

As anyone experienced with 3D printing knows, filament clogging up the extruder is one of the most common problems users come across. Most 3D printers do not identify or know how to deal with clogging, and remain fully powered and ready to heat up and operate when such an untenable condition exists. The result can be a mess, as well as a significant waste of time, energy and, most importantly, filament. Clogs can also have an impact on the overall printer life, adversely impacting the extruder and print head.

To solve this common issue, SUNLU S9 PLUS has what the manufacturer calls the first automatic clog detection module on the market. This module also automatically monitors the 3D printer and filament status, ensuring the entire operation goes smoothly. When a clog is detected, the 3D printer is prompted into low-power mode and prompts the user to stop the print and fix the clog. This feature is designed to significantly improve the success rate of printing – while also saving the end-user time and precious filament!

S9 Plus Comes Equipped with a Filament Dryer Box

Some of the most popular filament types are subject to absorbing humidity once opened and stored, regardless of the brand. SUNLU, an established expert in FDM filament, has 10 years of experience producing and testing 3D printing materials, giving them an edge on other 3D printer manufacturers.

Sunlu’s research and development team concludes that moisture can start to accumulate as soon as 6 hours after a new filament is removed from its protective vacuum sealed package. The optimal relative humidity for 3D printing and storing FDM filament is 25% to 30%, and the average living and working environment of the user contains around 55% relative humidity. This means that, in almost any environment, moisture absorption is inevitable.

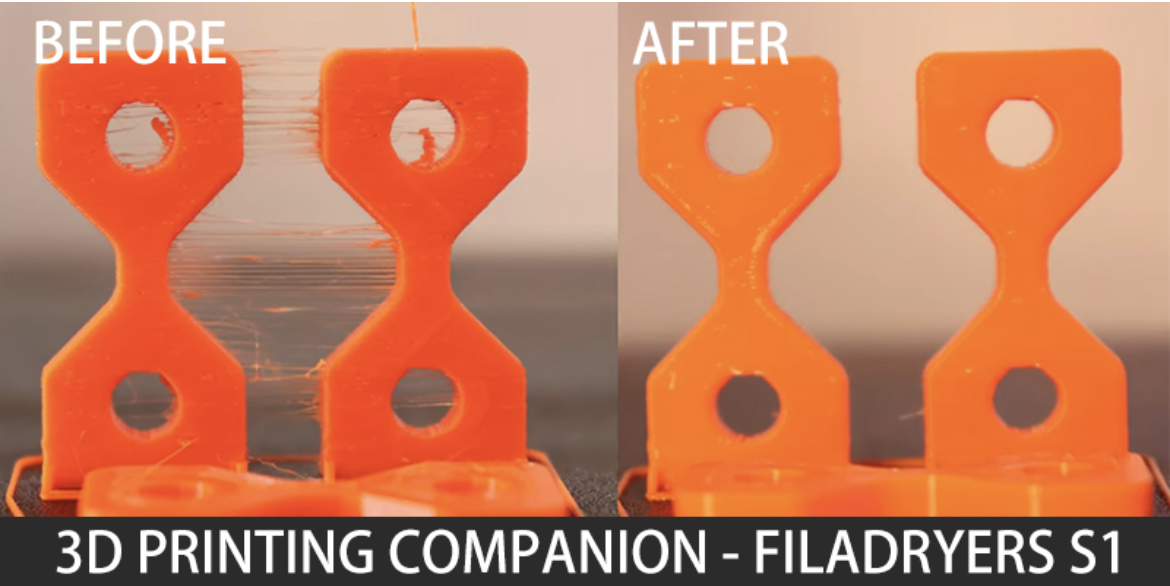

FDM filament with a high moisture level may result in prints with bubbles, whitening, faults, and other unwanted flaws. Approximately 40% of all print failures are likely caused by moisture that has been absorbed after the filament has been opened and put to use.

SUNLU S9 PLUS built-in control program for its fully integrated dryer box, called the FilaDryer S1 plus, that has a built-in fan and enables the dryer to be turned on and off by default. It also sets the operating temperature and time of the dryer according to the user’s preference. By reducing the humidity levels of your filament, this integration can help result in a print success rate of more than 40%.

Other Functions Found in SUNLU S9 PLUS

Outside of those industry-changing features, there are other popular functions that are found on the SUNLU S9 PLUS. These include:

- Auto-leveling

- Silent printing

- Power recovery printing function

- Filament break detection sensor

- Power-saving printing

- Extremely stable and durable frame

The Kickstarter campaign that aims to raise funding for the SUNLU S9 PLUS will officially launch on the crowdfunding platform on April 20, 2022 at 10:00 AM EST. If you’re interested in this filament-first machine, keep an eye on this campaign and look out for the super early bird price of $259!