It is bonkers to think that just five short years ago, the original Ender 3 settled itself into position as the go-to cheap printer. At the time, we said it was “a phenomenon,” and that “never have so many people shown interest in a low-cost 3D printer.”

That interest is firmly rooted today, enough so that even the likes of Bambu Lab, which said it wouldn’t make such a model of machine (a so-called “bed-slinger”, with the print bed moving laterally) is in on the act, unable to resist this seemingly endless supply of interest in cheap 3D printers.

Great news for us, then. More printers, more choice. What’s not to like?

Homogeneity. That’s what not to like. There are three models of Ender 3 V3, joining a dozen or so other Ender 3 3D printers, most of which can still be purchased today. It can be tricky keeping up.

We were scratching our collective heads going into this hands-on with the Ender 3 V3, wondering what really separates it from the Ender 3 KE and, to a lesser extent, the SE. While we’re not wholly convinced there needs to be three models of Ender 3, the answer to the question is resoundingly the baseline speed.

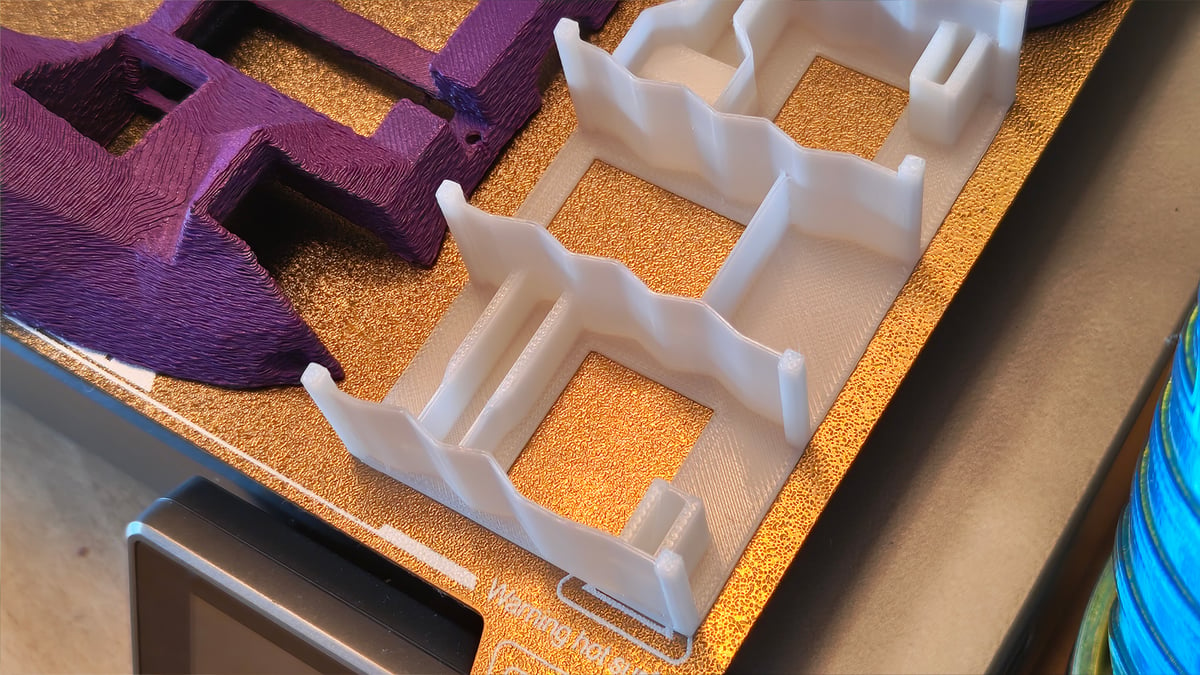

The Ender 3 V3 is rapid. Printing with it has been a mostly positive experience, although, there are clearly some things that are a bit “first-gen” about it, such as how it handles filament.

At a Glance

- Build volume: 220 x 220 x 250 mm

- Dimensions: 358 x 374 x 498 mm

- Weight: 7.83 kg

- Max. temp hot end: 300 °C

- Max. temp bed: 110 °C

- Other: Input shaping (G-sensor built-in), fully automatic bed leveling, Wi-Fi connectivity with cloud functionality

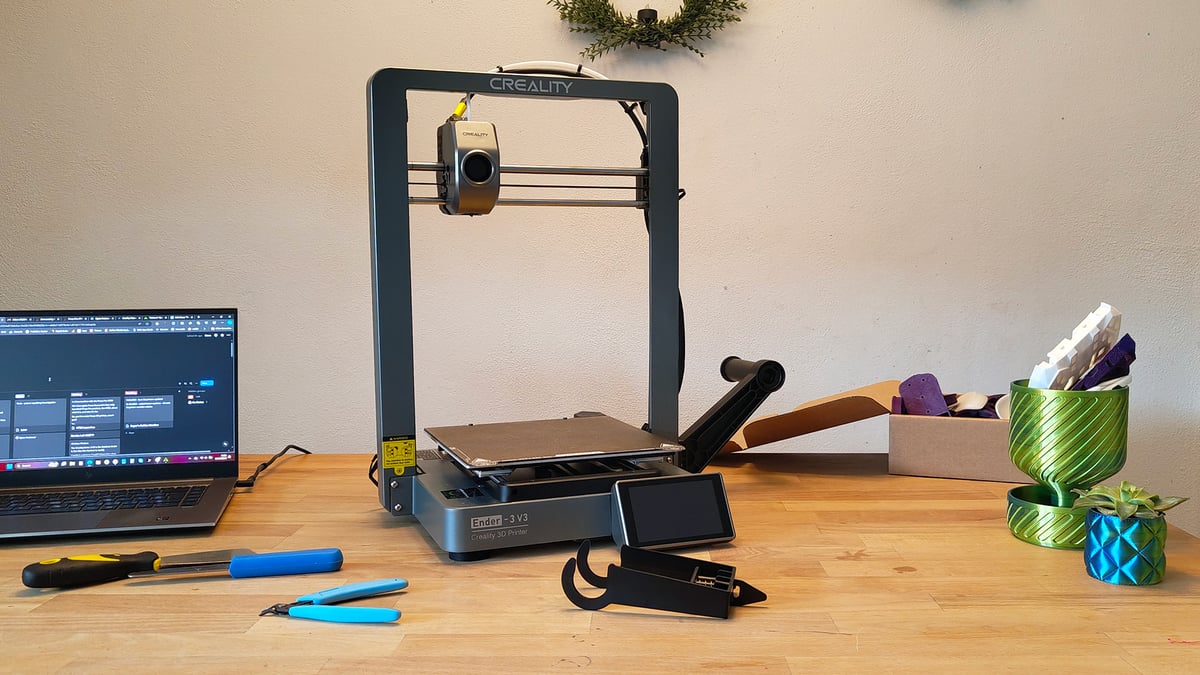

Available at the time of writing for $329, the Creality Ender 3 V3 is a bed-slinging 3D printer, as the Ender 3 series has always been. It sports a compact metal frame that is so simple to assemble, that you could outsource it to a seven-year-old (which is exactly what this writer did). For your (their) effort, you get a 220 x 220 x 250 mm build volume, CoreXZ kinematics to which Creality attributes faster printing, plus a new style hot end to keep pace.

But is it fast?

Quite! The unique selling point of the V3 is that it’s fast and packs all the trimmings to take advantage of this. Creality pegs the Ender 3 V3’s maximum print speed at 600 mm/s and acceleration at 20,000mm/s, speeds at parity with the company’s enclosed CoreXY printers. It’s an impressive feat, but as ever with marketed print speeds, this is a ceiling. You are likely only ever going to achieve close to this using high-speed PLA; the majority of the printer’s operations are much “slower” than this. The acceleration is where you really see the difference between the Ender 3 models.

Taking the CoreXY gantry and flipping it upright to serve as the tall-standing frame and motion system is not novel – the Voron Project did it years ago with the Switchwire. We’re not entirely clued in on the theorized gains from doing this, but it’s undisputable that it removes mass from the X-axis, and less mass means faster and easier to manage acceleration. Creality’s implementation includes neat touches like self-tensioning belts, and other changes to the broader design include a die-cast frame that simplifies the assembly and must add the needed rigidity. That last bit comes at the expense tinkerability – it is not going to be as simple to mod and upgrade the Ender 3 V3 as it was with previous entries in the series.

No doubt Creality’s thinking is that there’s no need to do any of that because, overall, the machine is another step toward a plug-and-play “it just works” experience.

Self-calibration runs on startup and that is largely the last you see of it. It self-offsets and does a stand-up job with first layers and bed adhesion, provided you maintain the bed and keep it clean and necessarily sticky with adhesion helpers. The basics of printing, which used to be tedious on a budget machine like this, are a non-issue. In our experience the printer does a decent job reigning in the vibrations and puts out smooth, optically fine prints.

One glaring backward step on the Ender 3 V3 that we must mention is filament loading, which can be nothing short of frustrating. Besides a filament sensor that will catch on anything other than an arrow-straight end of material (nigh impossible when filament comes on circular spools,) a spring-tensioned bracket is necessary to cover the spool and prevent a loom of filament from jumping off the spool every time the printer homes itself against the upper reaches of its Z-axis. Without this bracket, you are guaranteed to see tangles and failed prints. With this bracket, filament changes are steps longer than they ought to be.

What Else Is New?

Creality has a new nozzle style for the Ender 3 V3, which is shared with the also-new Creality K1C 3D printer. Called Unicorn, the nozzles have elongated melt zones and integrate the heatbreak. The appearance is not all that dissimilar from the Nextruder nozzles for Prusa Research’s XL and MK4 3D printers. One advantage they give is nozzle swaps that are less likely to put up a fight. The Unicorn nozzles come as standard with hardened steel tips, meaning the Ender 3 V3 is equipped for the abrasive filaments from the get-go.

Further benefits of the new nozzles should be tighter control against print issues like heatcreep.

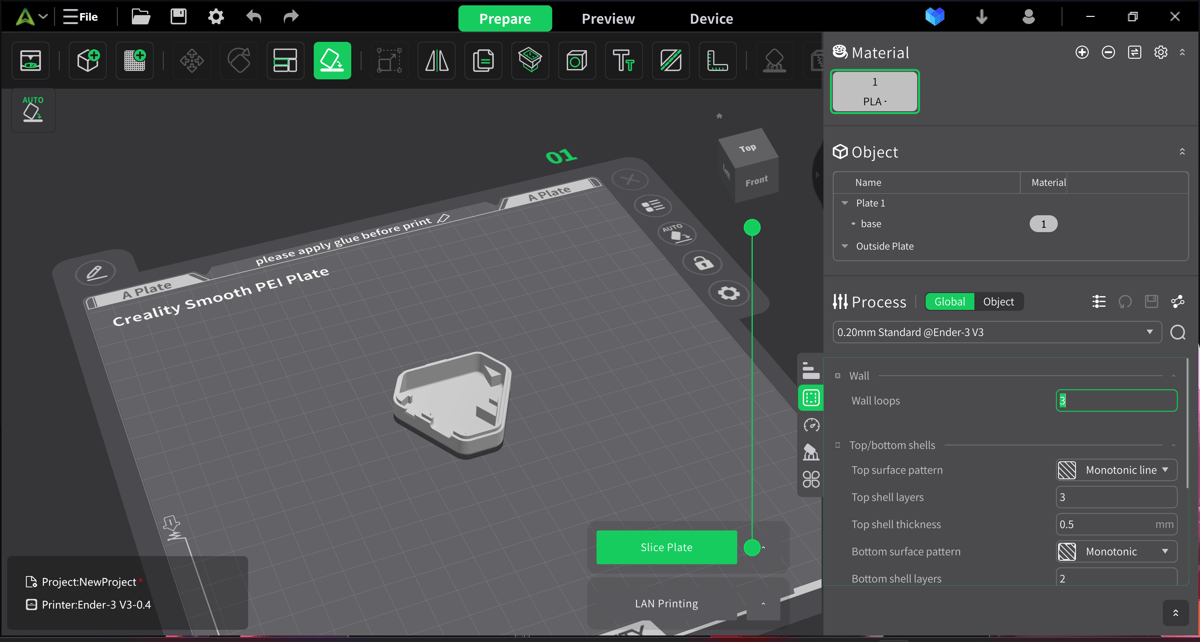

The Ender 3 V3 has a profile in Creality’s new Creality Print 5.0 software, too, which is a large leap forward from previous slicers from the company. It is, in essence, a reskin of Bambu Studio, which itself uses large chunks of PrusaSlicer. Between these two, there’s a solid foundation in place with deep enough print settings and individual, plate and project control that bring Creality’s software close to par with today’s popular open slicers. Obviously. Those slicers are there under the surface. Anyone familiar with the workflows offered by either will be right at home with Creality’s new offering.

What Gives, Then?

At $329, you can’t help but cast a sideways glance at machines like the Bambu Lab A1 ($399) and wonder how the Ender 3 V3 compares. Having used both extensively, we think it comes down to the smarts of the machine. Both are blazing fast and can produce high-quality prints with no effort on your part, but while the Ender 3 V3 self-calibrates, it can’t tell you when something has gone wrong with the print. It’s not determining the flow (or lack of) of the filament, nor can it “listen” to itself and tune its performance to make its motors quieter, as the A1 can. There is a quiet mode, we’ll grant that, but as far as features go, this is neither novel or new.

In many ways, it is the traditional barebones printing experience you’d come to expect from an Ender 3D printer, with a lot of polish in some areas, but a misstep in others.

Looking down the range, the Ender 3 V3 KE offers an awfully similar amount of printer for just $239, with the main sacrifice being a smidge of print speed and the ability to recalibrate input shaping whenever you want (an optional G-sensor is required). This is where things get too homogenous for our liking. The KE is also Wi-Fi-equipped and has a profile in Creality Print 5.0, meaning the software and user experience are identical.

Further beneath this, the Ender 3 V3 SE is a little slower still and takes a hit to usability with a manual control knob, and (at the time of writing) lesser slicer compatibility. It costs less than $200, though. Neither it nor the KE is as frustrating to load with filament as the V3.

Little things like this matter more nowadays; Creality can’t wholly bank on the popularity of the Ender 3 name anymore, and releasing three similar-ish models confuses things – particularly when the V3’s performance overlaps with the company’s flagship K1 3D printer by quite some margin. They’re all great in their ways. Filament loading aside, the V3 is a great 3D printer; it’s just not quite the no-brainer upgrade we hoped it might be

This is just our initial impression, though–we’ll continue to print and update this article if our opinion shifts one way or another.

Just as this article was ready to publish, our Ender 3 V3 unit developed a fault with the leveling probe, rendering it inoperable. Creality swiftly sent a replacement unit. Here's hoping it was a one-off. If you have an Ender 3 V3 and experienced the same issue, drop me a line matthew@all3dp.com.

License: The text of "The Creality Ender 3 V3 Is Rapid, But Also Hard to Justify" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.

Stay Informed, Save Big, Make More

Stay Informed, Save Big, Make More