The Prusa Core One has been out for a few weeks now, and the community has had time to explore the ins and outs of the device, and start comparing it to the competition.

One of the most interesting first-impression videos we saw was by popular 3D printing YouTube channel CNC Kitchen, where Stefan Hermann and fellow YouTubers compared models from the Prusa Core One, Original Prusa MK4S, MK3, and Bambu Lab X1C. The sentiment was positive overall (a trait shared with our Prusa Core One first impressions), but there was some criticism of the Core One’s overhang performance, specifically in the Clockspring3D torture toaster test.

Though social commentary over the Core One’s overhang performance didn’t gain much of a foothold, we noted some disappointment over the perceived step back in quality, so decided to add another point of comparison to the conversation – and asked Prusa Research some questions about chamber temperatures and how it sees the results.

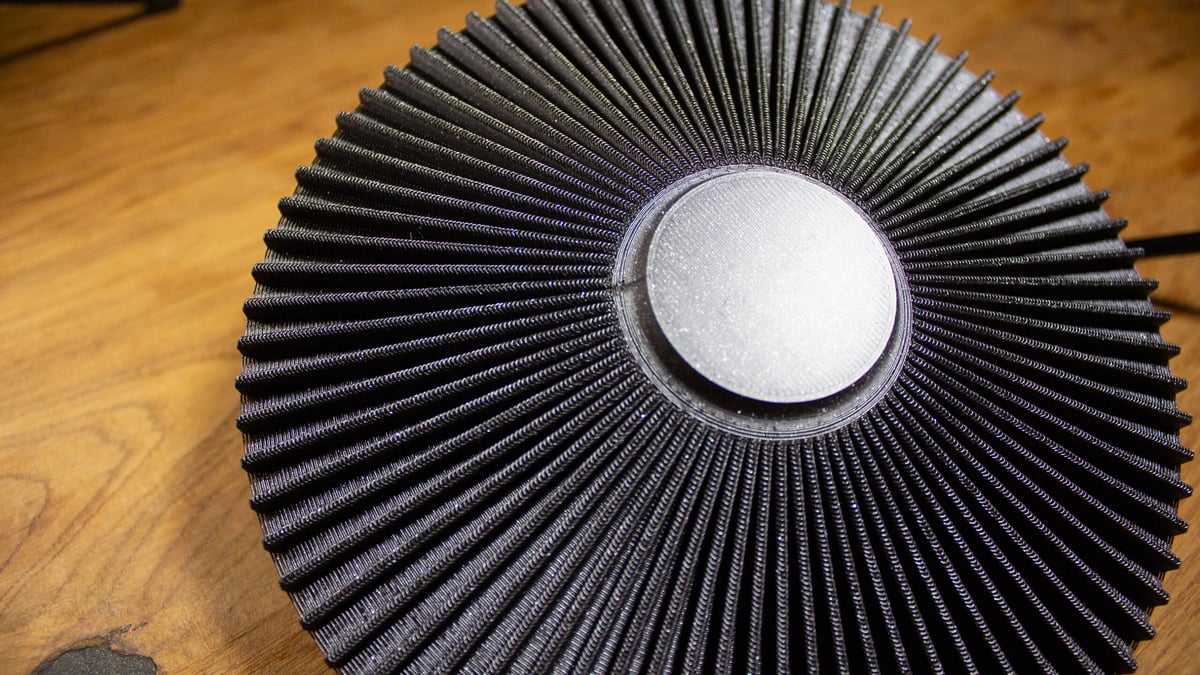

The Toaster Test

We ran these tests exclusively with Prusament PLA on default 0.20 mm layer height profiles. In the images below, green parts came from the Prusa Core One while blue parts came from the Original Prusa MK4S. We did also run the blue Prusament through the Core One to ensure color didn’t create a noticeable difference in quality; in this case, it didn’t.

Long story short: our torture toasters show similar results to what we saw from CNC Kitchen, if maybe a little less severe. Overhangs produced by the Core One at 70º and 80º are noticeably poorer quality than the Original Prusa MK4S – if only marginally so.

I praised the Core One’s overhang capabilities in our first impressions article when Prusa Research’s 75º Scandic Plate model printed in excellent quality, so I was surprised to reproduce imperfect overhangs at 70º and even shoddy edges starting at 60º on one side.

Other overhang tests, a simple overhang test and Prusa’s star overhang test, show similar results. A very close, but undeniable quality difference.

What’s the Deal?

This all feels rather nitpicky as a point of criticism; the results at extreme overhangs of 70º and up are within what I would usually amount to a margin of error, and CNC Kitchen made a similar point adding “this is something you should consider if you primarily print with PLA”. But Prusa Research markets the Core One as having cooling that “enables flawless printing of 75° overhangs” and, though it can certainly achieve that in models like the Scandic Plate, “flawless” 75º overhangs appear inconsistent, and don’t match the experience of the last 3D printer the company marketed that way – the MK4S.

In an interview with All3DP Prusa Research CMO, Rudolf “Ruda” Krčmář, said the company considers the issue “marginal”. He explained that, ultimately, an open-frame 3D printer will always be superior for low-temperature materials like PLA and PETG, but the Core One has been designed to minimize the difference. That’s also why, importantly, the MK4S still has a place in its product offering.

In CNC Kitchen’s hands-on, the Core One reported chamber temperatures of “nearly 30 ºC” despite a target chamber temperature of 20 ºC. We had a similar experience, with similar ambient temperatures of ~22 ºC, a 20 ºC target, and chamber temperature that sometimes reached 30 ºC.

When it comes to the chamber temperature and server fan settings, Krčmář said the chamber temperatures are within expectations for a targeted 20 ºC chamber temperature, as the feature is not intended to be a hard setting.

“The printer knows you would like to run it at a certain chamber temperature, and the lower you set that number, the more aggressive the fans will kick in,” Krčmář said. “It also calculates the melting temperature of the material, so you know that for PLA a temperature of 27 ºC is safe. As a result, the fan speed slows.”

Essentially, an algorithm balances the target temperature, material melting temperature, and fan volume to prevent undo noise, but more power will be used if temperatures start slipping higher. It’s like a PC fan curve.

That said, Prusa won’t allow the fans to perform above 40% of their capacity automatically in a standard operating mode. But Krčmář emphasized that users are able to access the additional 60% overhead if they choose – and noted that 100% fan speed would allow chamber air to be fully exchanged in just two seconds.

As far as our ongoing review of the Core One is concerned, we can see the machine is certainly capable of high-quality 75º overhangs, but it’s not consistently flawless – certainly not like it was on the MK4S.

It seems like the enclosure is probably responsible for the difference, but it could also just be mild growing pains from new kinematics, or a software issue like – as CNC Kitchen suggested – Prusa’s factory input shaping finally reaching its limit on the high-end of the Core One’s capabilities.

Prusa has a track record of its releases improving over time, and we’re confident that if this small gap can close – it will. End users will decide if the difference is enough for them to opt for an open-frame 3D printer, but I would stress that this level of quality on an enclosed 3D printer is really impressive and, as CNC Kitchen also made a point of noting, the print quality is very high overall. Though it wasn’t the focus of this article, we did notice improved surface quality from the Core One.

On Print Testing

It’s worth mentioning that we first ran these tests with a high-flow ObXidian nozzle on the MK4S and found different results after swapping back to a stock high-flow brass nozzle. Each nozzle produced some prints better and some prints worse than the Core One, which seems to support the idea that any issue here is within the margins of error.

It’s important to be clear: comparison tests like this are rarely conclusive. We can only relay our experiences, and print tests like these are more about performance indication than anything. Your mileage may vary.

So, if you have an MK4S or Core One, it’s always a service to the community to print these tests yourself and share the results. Comment below and let other readers know how the prints turned out for you, and which materials and settings you’ve used. The more results we all see, the better. If you don’t have a Prusa Core One, check out our first impressions for a broader overview of the machine.

License: The text of "The Prusa Core One’s Overhangs Are Very Good – But Don’t Quite Match the MK4S" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.

Stay Informed, Save Big, Make More

Stay Informed, Save Big, Make More