The 3D printing market is booming, and with it comes a shift from prototyping to end-use production. This means that an increasing number of users require a high-performance, reliable, and efficient 3D printing solution that can handle a range of manufacturing-oriented tasks, as well as a variety of materials.

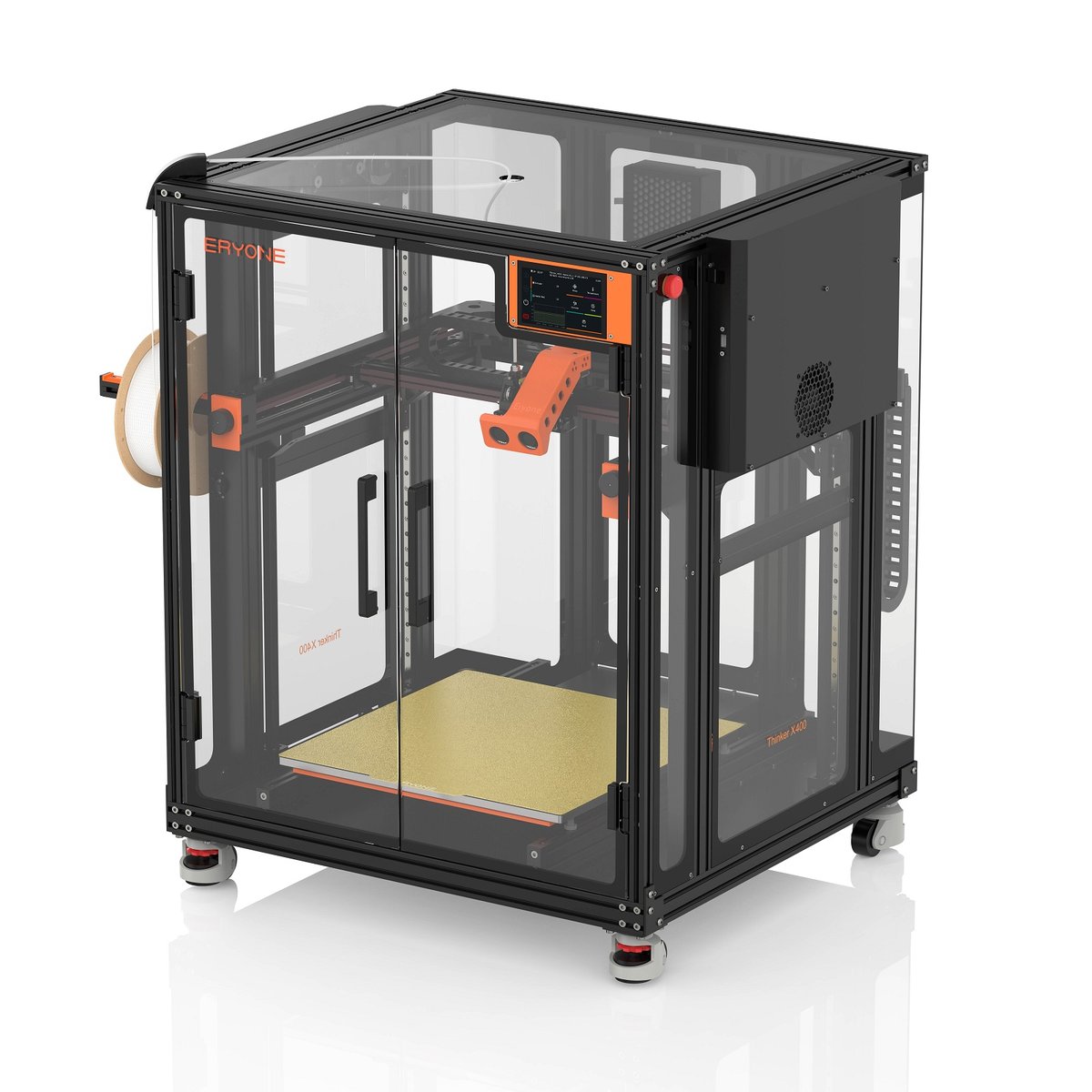

Eryone’s Thinker X400 aims to fill that gap, enabling both the creation of rapid prototypes and highly accurate end-use parts – perfect for those operating or managing print farms in manufacturing environments.

Unmatched Performance & Efficiency

The Thinker X400 aims to redefine industrial 3D printing with its exceptional cost-performance ratio. A Core XY structure with linear guides provides unmatched stability and precision for flawless results with every print, while a large 400 x 400 x 400 mm build volume allows for the creation of large, detailed parts.

The Thinker X400 is also no slouch when it comes to speed. It can print as fast as 500 mm/s, allowing manufacturers to drastically reduce production time while maintaining top-tier print quality.

Thanks to its dedicated 3D printing farm management software, the Thinker X400 is an ideal choice for large-scale print operations. Combined with its high-performance cooling system that ensures precise temperature regulation and a design that aims to reduce print noise, and you’re looking at a machine that is well-suited to a variety of work environments.

Seamless User Experience & Intuitive Design

Ease of use is at the core of the Thinker X400’s design. Unlike conventional industrial printers, it features an all-in-one design that requires minimal setup – just attach the filament holder and PTFE tube, and you’re ready to print.

The printer’s 25-point auto-leveling system ensures a perfectly calibrated print bed, eliminating manual adjustments and enhancing first-layer adhesion, while automated features such as filament run-out detection, automatic filament feeding, and filament knot detection reduce material waste and prevent printing failures.

Users control these features via a five-inch HD touchscreen, which provides an intuitive user interface that simplifies navigation.

A magnetic, flexible double-sided PEI plate allows users to effortlessly remove finished prints and ensures strong adhesion during printing. Additionally, the modular extruder design allows for quick disassembly and maintenance, reducing downtime and extending the printer’s lifespan.

Versatile Material Compatibility & Safety Features

The Thinker X400’s enclosed print chamber supports an extensive range of materials, including PLA, PETG, ABS, ASA, TPU, PA, PP, PLA-CF, PETG-CF, ABS-CF, PA-CF, ASA-CF, and PET-CF*. This versatility makes it an excellent choice for applications requiring strong, flexible, or heat-resistant components.

To ensure safety and environmental sustainability, the Thinker X400 is equipped with an activated carbon air filter, which captures harmful emissions and maintains clean air during the printing process. Finally, a built-in camera monitoring system allows users to oversee prints remotely, providing an additional layer of control and security.

*Some materials, such as PA and PP, require special adhesive during printing.

Revolutionize Your Manufacturing Process with the Thinker X400

Whether you’re managing a 3D printing farm, CNC machining factory, or electronics manufacturing plant, the Thinker X400 is designed to streamline operations, enhance productivity, and deliver high-quality results.

With a focus on speed, stability, and ease of use, this production-grade 3D printer is the ultimate tool for those looking to scale up production while maintaining top-tier precision and efficiency.

A Kickstarter campaign for the Thinker X400 is just been launched. There, you can learn more about the printer and ensure that you are among the first to receive one once they ship.

License: The text of "Thinker X400: The Next Generation of High-Speed, Precision 3D Printing" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.