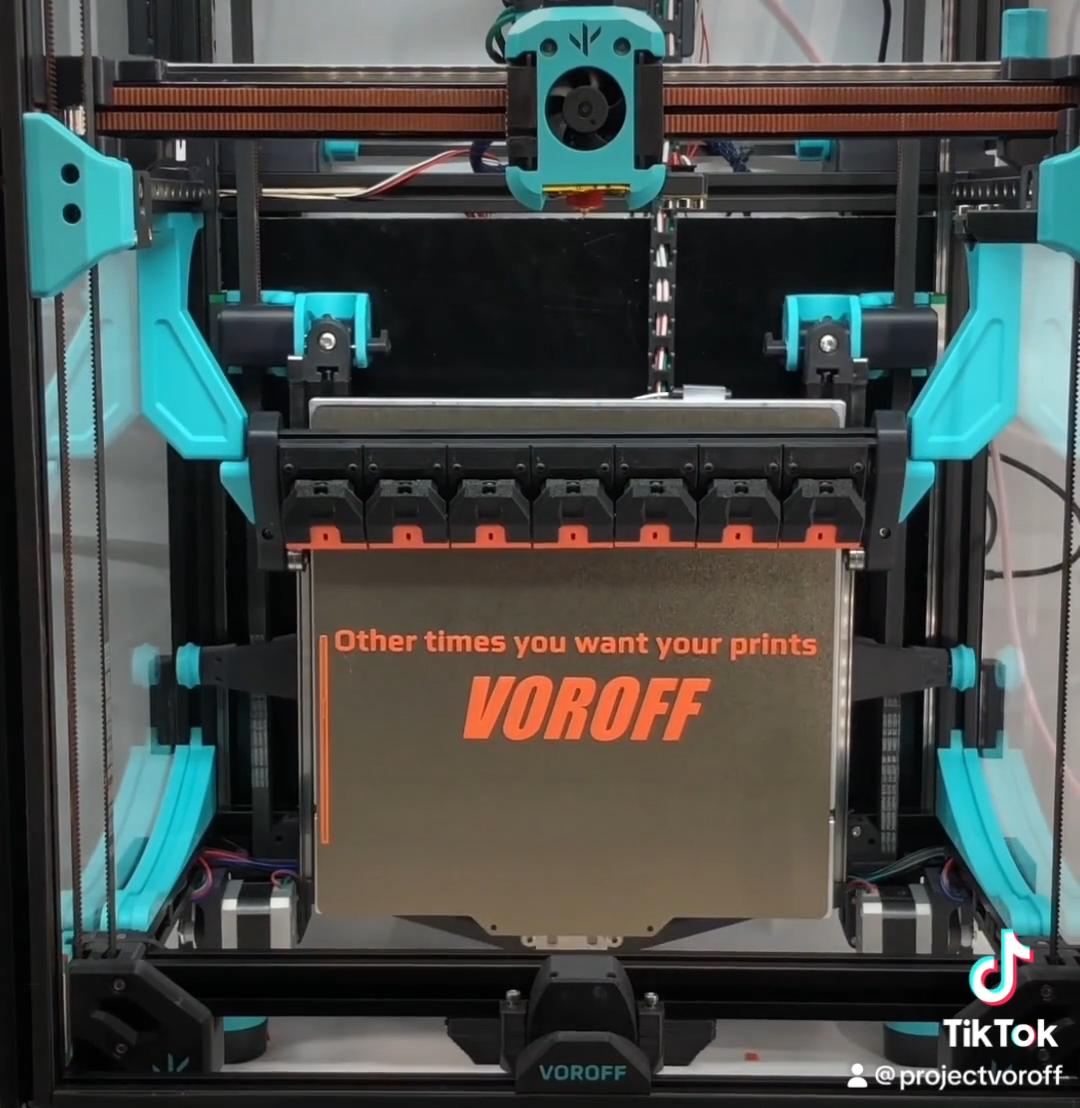

A recently revealed open-source project based on a mix of Voron designs, the “Voroff” boasts a CoreXY 3D printer with automatic print ejection that should pique the interest of print farm operators.

When released, the project plans to offer a unique “continuous printing system”, by rotating the print bed and raising it so a scraper bar can remove prints. The 3D printer is based on the form factor of the popular (and also open source) Voron Trident, but also takes notes from the Voron 0, Voron 2.4, and GitHub user gsl12’s Tiny-M project – a compact printer based on the Voron 0.

“The bed rotating and scraping assembly is all our own concoction. Yeah, it adds two more linear rails. But who doesn’t love linear rails? The electronics being on the back is also nice for serviceability,” says Josh Ariel, who, along with Baylin Bridges, makes up the two-man Voroff team. “The name is obviously a cheeky tribute to Voron: sometimes you want your prints ‘Voroff’. It is, however, its own build, from scratch.”

The Voroff project arose from frustrations that Ariel and Bridges experienced while running a print farm consisting of “about nine” Ender 3 V2 3D printers.

“While they worked reasonably well, they required substantial maintenance which took a lot of our time – and they were fairly limited in what type of geometries they could eject, the speed at which they could print, and the materials we could use,” Ariel said. “Both of us being engineers, we thought we could design something without ‘too much effort’ that would have Core XY speed, the reliability and precision of linear rails, and a truly robust scraping mechanism.”

“The scraper bar [also] has a unique mechanism that allows it to press to the bed and scrape a bunch of different materials, [such as] TPU, ABS, ASA, and PLA,” he added.

According to the team, this design reduces stress on the tool head gantry while leveraging gravity and the scraper to remove spaghetti, failed prints, or finished parts – even if they are only a few layers high.

Automatic print removal has long been a topic of interest, especially for print farm operators, as they hold the potential to vastly improve overall efficiency. Practical options, however, are fairly limited.

There’s the OctoPrint Continuous Print plugin, which features an automatic bed clearing function, but usually requires the user to outfit their machines with a method of doing so.

Perhaps foremost on the automatic print removal scene is 3DQue’s AutoFarm3D (formerly “Quinly”), which uses a tilt system – albeit one that appears less drastic than the Voroff’s – and uses the printer’s print head, rather than a scraper, and a specialized “VAAPR” print bed to remove parts.

Bridges said the Voroff will boast a smaller footprint than the AutoFarm3D, “as parts just exit out the bottom, presumably into a bucket, chute, or conveyor”.

“The four Z-drive assemblies are mostly stock from the Voron 2.4 at the moment, but eventually we’d like to move those to the top of the printer with our own design to make it easier and more flexible to have storage and a door underneath,” Ariel said.

While the Voroff isn’t yet ready for public eyes, the Voroff team is hard at work to make that happen. When the time comes, the idea is for the machine to be open-sourced. The team also plans on selling kits – and potentially fully assembled printers.

“We are buttoning up the design a bit before we’re ready to release it for others to work with,” Bridges said. “We do have a BOM, and it’s kind of a beast, with 107 unique printed parts, so far.”

Release date or not, it’s exciting to see another entry headed to the automatic print removal space – especially one that seems to function as effectively as the Voroff. In the meantime, you can check out the Project Voroff website for a bit more information. There, you can also subscribe to its newsletter so you’ll be first in line for updates.

You’ve read that; now read these:

License: The text of "This Voron-Based 3D Printer Automates Print Removal, Will Be Open Source" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

Stay Informed, Save Big, Make More

Stay Informed, Save Big, Make More