Magigoo is an all-in-one 3D printing adhesive which makes it easy to adhere and release parts from a heated build plate of an FDM 3D printer. Now, Thought3D, the Malta-based startup behind Magigoo, is releasing new specialty mixes of its product designed for industrial use.

The original formula for Magigoo works with commonly 3D printed plastics such as PLA, ABS, HIPS, PETG, TPU. It is sold in over 25 countries as an alternative to glue sticks, sheets, and sprays.

Although it was released in late 2015 for glass and aluminum surfaces, the 3D printing community inspired Thought3D to begin evolving the formula so it would perform more consistently with other bed materials like Kapton or PEI sheets.

Now, the company is gradually rolling out new and improved formulations which provide even better results for engineering-grade materials. Some changes to the product include using natural ingredients and making them biocide and solvent free. Furthermore, this new formula is more resistant to environmental spoilers.

New Magigoo Formulation for Industrial Use

Thought3D has also been improving the formula to resolve common sticking and warping problems for large format 3D printers and engineering-grade plastics such as Polypropylene, Polycarbonate, and Nylons.

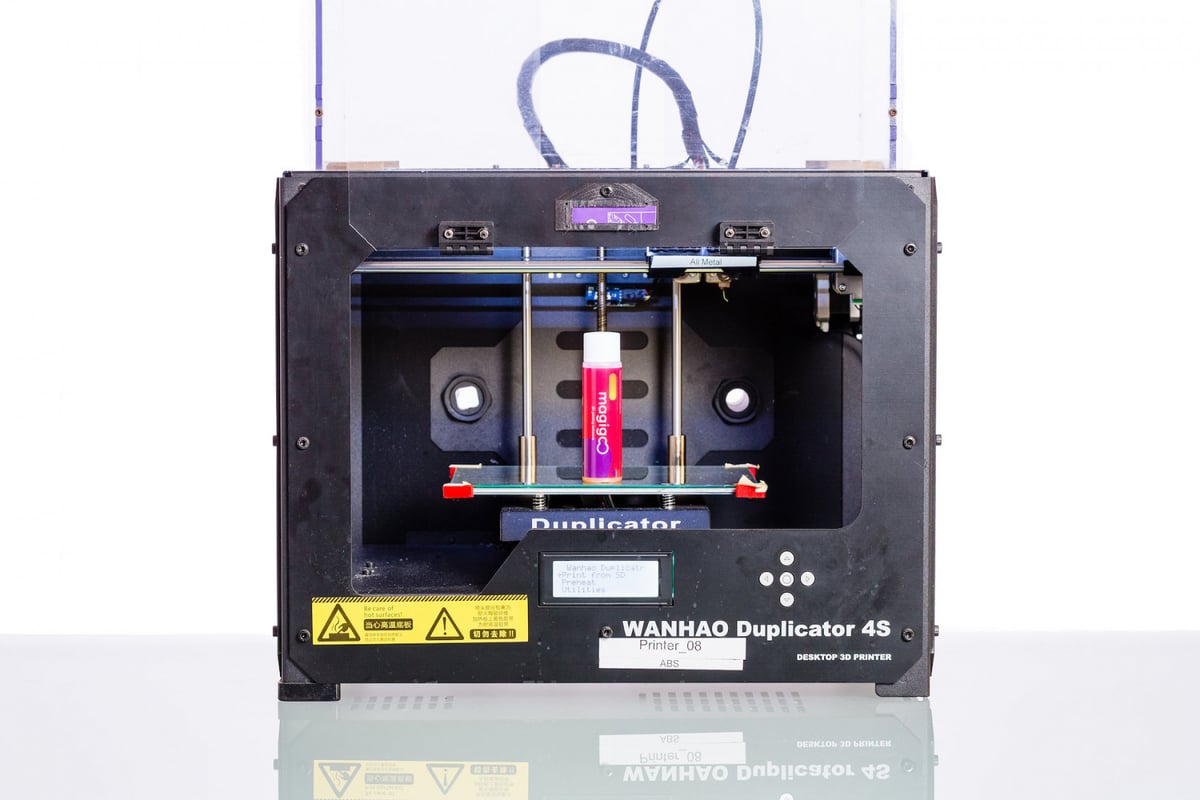

In fact, this past year, a super-sized Magigoo was released to serve BigRep and other large-format 3D printers. And, as FDM is being used more for industrial applications, even more formulations of Magigoo are being launched in the near future.

“The manufacturing industry wants to 3D print with materials it is already accustomed to. From a practical perspective the variety in materials is needed because each presents its own beneficial properties, such as the required hardness, durability to wear and tear, robustness, flexibility, temperature durability and chemical resistance,” said Dr. Keith M Azzopardi, the lead scientist behind Magigoo, explains.

Dr. Azzopardi and his team have decided that a “one-product-fits-all solution” was inadequate for the unique properties and challenges that each 3D printable plastic presents. That’s why they decided to create multiple mixes geared towards specific materials, providing customers with customized solutions that fit their needs.

Thought3D is rolling out new layer adhesives for Polypropylene, Polycarbonate, and Polypropylene with Glass Fibre. Each new product is named according to the corresponding 3D printing material, including Magigoo PP, Magigoo PP-GF, Magigoo PC and Magigoo PA.

To distinguish them from the original formulation, Magigoo Pro professional use products will come packaged with grey and orange labels.

License: The text of "Thought3D Releases Speciality Mixes of Magigoo for Industrial Use" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.