The latest version of E3D’s popular RapidChange Revo lineup is the Revo CR, designed as an easy drop-in replacement for the MK8-style hot ends on Creality 3D printers like the ever-popular Ender 3 series.

Last year E3D announced its RapidChange Revo hot end system to much anticipation. Launching with three variants: the Six (V6), Micro, and Hemera XS, the series has grown to include the Revo Voron and, most recently, Revo CR.

Revo hot ends are appealing for many reasons, but the Revo CR strikes us as uniquely suited for those looking to take their first steps into modding 3D printers. If you haven’t modded your 3D printer before, taking things apart for the first time can be a little daunting. Where do you even begin? Without having some sort of background experience, exciting new parts that bring 3D printing forward can easily pass you by.

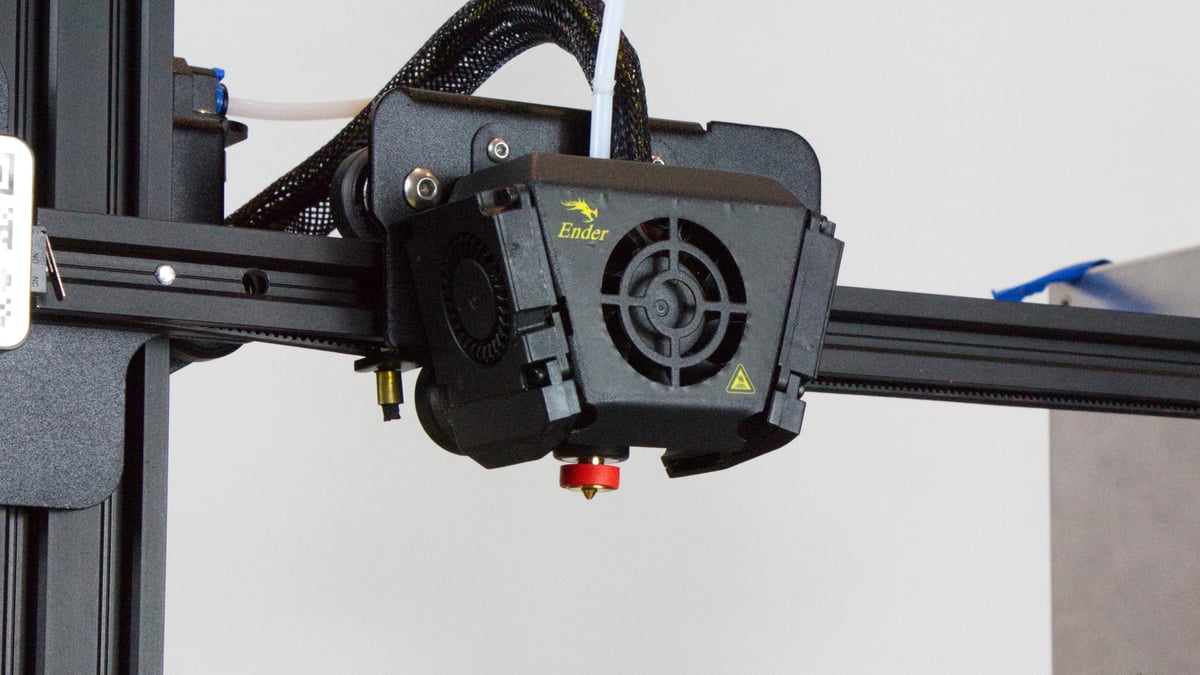

That’s where 3D printer-specific part variants can be a huge help, so we’re taking a look at the Revo CR and installing it in our otherwise stock Ender 3 Max.

What’s Rapid About the Revo?

There’s more to it than that. The Revo hot end uses a compact circular ceramic heater block (E3D’s patented HeaterCore) that has a positive temperature coefficient which E3D says reduces thermal runaway risks by requiring less power as heat rises. A nice little hot end all around.

Why Start Modding Here?

With the Revo CR, E3D has introduced a practical drop-in replacement for MK8-style hot ends that can help those with compatible Creality 3D printers get started. More than just matching mounting holes on the cold side, the Revo CR includes a 100K NTC thermistor, which matches the response time of Creality stock thermistors and eliminates the need to tweak the firmware after installation.

Basically, the Revo CR hot end adds a practical and novel utility without any 3D printed or otherwise user-driven modifications, including firmware, that bring some potential for user error. Installing simple drop-in parts like the Revo CR is a great way to familiarize yourself with how the hot end and mainboard connect and get started taking the shroud off and various wires out. But, otherwise, it’s plug-and-play, baby!

First Impressions

In the Revo CR’s box, you get the hot end itself plus cable extensions for the heater block and thermistor; the red 0.4-mm nozzle, already threaded into the hot end; and, if you ordered a kit of four Revo nozzles, three other nozzles sizes: a yellow 0.25-mm, blue 0.6-mm, and green 0.8-mm. A pink 0.15-mm nozzle is also available from E3D, but it’s not a part of the bundle. The yellow 0.25-mm nozzle is likely to work for your extremely small and detailed prints in any case.

You can see why the Revo CR is an upgrade from Creality’s stock MK8 hot ends immediately. You’ll quickly notice the Revo CR’s heat sink curves out at the front, giving more room for heat dissipation. Some users have mentioned this enlarged heat sink gets in the way of custom fan setups, but it should be easy enough to accommodate.

The cabling is also clearly of a higher quality than that on the stock hot end. Both thermistor and heater block cables are braided and short, connecting to extensions that make removing the hot end far easier in the future. The crimped heater cables with ferruled ends are an important safety upgrade over Creality’s default tinned wires. The thermistor ends are a bit of a miss, though, with a slim Dupont connector instead of the Ender’s JST XH. This is ultimately fine – the Dupont connector works fine, but it would be better if it matched the Ender mainboard’s connector to ensure it doesn’t come loose.

These cables have proper strain relief under a braided cable cover, which is itself a nice upgrade from a simple Kapton tape cover. They’re stiff – good for safety – but fit snugly into the Ender 3 Max’s stock print head shroud. We wonder if other Ender 3 model shrouds might be a tighter fit. Fortunately, you can spin the heater block to route the cables in a different direction if needed.

The Revo CR uses a round heater block completely separate from the heat sink. When a Revo nozzle isn’t holding the two sides together, a small tension spring, which keeps the heater block in place when a nozzle is threaded through, is all that attaches them. The entire Revo hot side, both HeaterCore heater block and nozzles, are proprietary, so you can only source replacements from E3D. That’s especially important for consumable nozzles.

Beyond its general quality and quality-of-life improvements, the Revo CR hot end is also all metal. As such, it’s able to reach up to 300 °C and facilitate high-temperature material printing — but there’s a caveat. High-temperature materials, like nylon and polycarbonate, are also often abrasive, and Revo nozzles are currently only available in brass. A “wear resistant” option is on the horizon in the form of E3D’s ObXidian nozzles. Due to launch soon after the Revo, setbacks pushed the ObXidian to October 2022, some 12 months later than planned. Users excited about high-temperature printing with abrasive materials may want to wait until then.

But, hey, at least it won’t be hard to swap out these nozzles once they are finally released. That is the whole point, after all.

How Well Does It Work?

The Revo CR is a drop-in replacement for the MK8 hot end. Simple as that. Using the same size nozzle, we found our settings were perfectly interchangeable to good results. That said, it is still a different hot end, so you’ll have room to tweak things further. For one, given the Revo’s larger single-piece brass section that looks closer to a volcano-style nozzle than the MK8’s shorter nozzles, you may find you can push your print speeds a little higher due to the slightly larger melt zone.

E3D’s big pitch for the RapidChange ecosystem is how easy it makes swapping nozzles, and it really does. Some critics have pointed out that nozzle changes aren’t all that time-consuming once you’ve done it a few times, which is certainly true, but the Revo’s toolless changing adds a liberating simplicity. Eliminating any need to brace the heater block or to hot tighten the nozzle greatly reduces your chances of causing damage or getting burned, which shouldn’t be understated. Eliminating these small challenges removes any hesitation, making nozzle sizes something that can regularly be chosen on the fly.

We would suggest making one small change to your start and end G-code for best results, though: instruct your 3D printer to extrude a small amount before the nozzle wipe and to retract the filament at the end of a print. Otherwise, hardened filament will stop you from swapping nozzles on a whim and, instead, force you to heat up your printer to retract the material and let the hot end cool down again before you can swap it out. That’s not in the spirit of the system.

We won’t go into detail here about why you might want to use a larger or smaller nozzle diameter. If you’re interested in learning about that check out our guide to Ender 3 nozzle size choices. Suffice it to say that, in the most basic sense, nozzle bore diameters are a balancing act between speed and detail. Larger nozzles print in larger layers, which sacrifices detail to push more filament faster. Smaller nozzles do the opposite, pushing less material out but achieving higher resolution all around.

We started things off with the 0.4-mm nozzle, leveling our newly modded Ender 3 Max and printing a 3D Benchy with our old Cura profile to see how it compares. The part printed well within expectations. Extrusion was a little more even, but it’s clear, given the slightly poorer layer uniformity, that we can reduce the flow rate a touch given the larger melt zone. The new hot end did introduce some stringing, so retraction and heat will need to be tuned to manage it. We monitored temperatures via OctoPrint, which reported stability – no need for PID tuning.

From here, we changed to the 0.8-mm nozzle and immediately printed a stand for the Filler filament holder that the ~8-hour print time with the stock 0.4-mm nozzle has put us off attempting. The larger nozzle cut this print time down to just 4 hours.

We encountered a problem with warping here, but it was because of user error. We’d rushed to the larger nozzle without adjusting our printing temperature and so, because of the wider bore, our filament wasn’t heating up enough and not adhering properly. Adding 20 °C to our typical 0.4 mm printing temperature sorted the issue, and we printed a fantastic-looking Moai figure to confirm.

Finally, we tried the 0.25-mm nozzle, printing a Bugbear miniature from Lost Adventures Co. with a new filament. We had some major issues with under extrusion here while finding the right temperature but, again, 20 °C higher than our preferred 0.4-mm nozzle temperature did the trick.

Here we also experienced a minor problem from one of the Revo’s practical limitations: bed leveling.

You need to adjust the Z offset every time you install a new nozzle. There’s just no getting away from it, each nozzle will have very slight differences that must be accounted for. Without an integrated sensor like a strain gauge or load cell, you’ll have to manually apply an offset, and Revo nozzles are no exception.

To do these adjustments on the fly, we printed parts with slightly larger skirts than we typically would, giving us time to baby step a new Z-offset before the print started. It was never especially far, but the 0.25-mm ended up being the furthest. Still, we printed our Bugbear too close to the bed and had trouble getting it off, resulting in some damage to the base when we eventually pried it free.

That said, we were extremely pleased with the 0.25-mm nozzle’s print quality. The part printed with little stringing, but it could likely be further managed. Details printed exceptionally well, in far greater detail than we typically expect of FDM with barely visible layer lines. This is on a barebones budget printer, and one with a taller-than-average gantry that makes it less than ideal for this sort of detail work. Versatile.

Is It Worth It?

Here’s the catch: at around $95 from resellers or ~£70 (~$80) from E3D directly, the Revo CR is pricey. And that’s for the hot end with just a single nozzle. There are other drop-in hot ends such as Micro Swiss’ All-Metal, or the Phaetus Dragonfly BMS, both approximately $60 and both fine options.

Then there are the nozzles themselves. Since E3D opted to patent its entire hot side design, heater block, and nozzles, the company is your only source for replacement parts. And these heat break integrated nozzles are pricey at $26 a pop.

Getting your hands on them in the US seems to be somewhat difficult, too. Matterhackers is one of a handful of stores stocking the parts and sells the non-standard sizes (all but the 0.4 mm) exclusively in a pack for $68. Just need a new 0.8 mm nozzle? You might have to order it from E3D in the UK directly and eat whatever shipping and import fees it charges. This is before we rehash the delay on E3D’s wear-resistant ObXidian nozzles and the lack of alternate options for the Revo.

All that said, though there are cheaper hot ends out there, there are also more expensive options. The Revo CR sits firmly in a mid-range with an offering that adds excellent utility. Though the nozzles may be expensive, they add tremendous value in terms of ease of use and, at least somewhat, a stronger melt zone.

We’ve had a fantastic experience with the Revo CR and feel that it provides a touch of extra power compared to Creality’s stock MK8, reduces the risk of damage and injury while changing nozzles, and makes frequently changing nozzle sizes more realistic for those who typically just can’t be bothered.

License: The text of "E3D’s Drop-In Ender 3 Hot End is an Easy Upgrade for Toolless Nozzle Swapping" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.