In a landmark technological stride, the University of Arizona’s microcampus in Kazakhstan, Kozybayev University, has received its first industrial metal 3D printer – the HBD 350. This sophisticated machine, manufactured by HBD and supplied in partnership with Top 3D Shop, is set to revolutionize the university’s research and development capabilities.

What is the HBD 350?

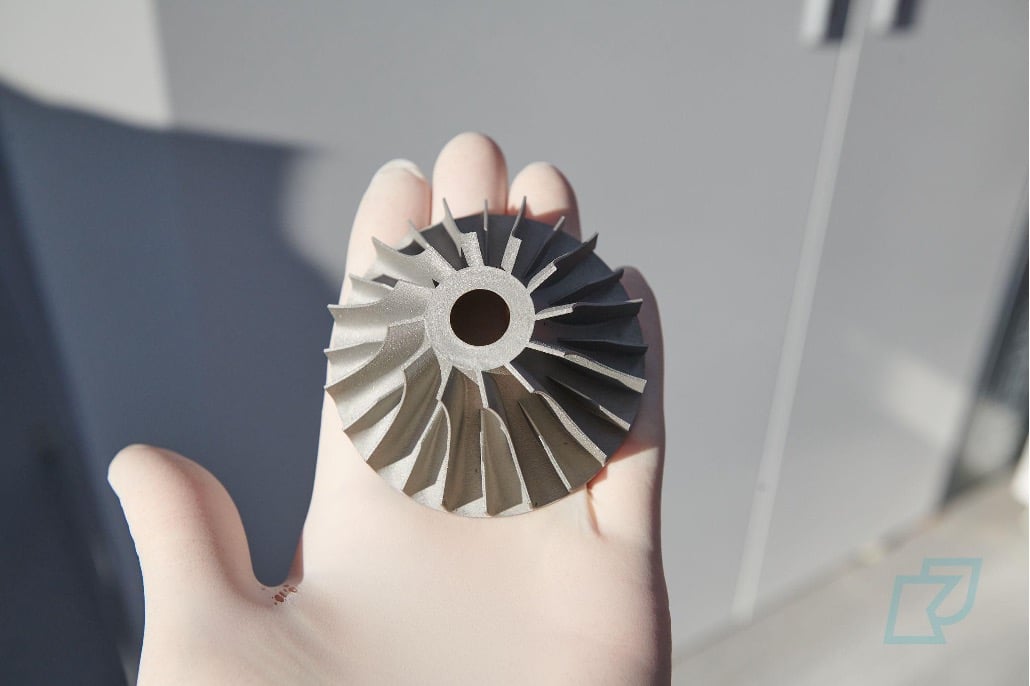

The HBD 350 is an industrial-grade 3D printer that harnesses selective laser melting (SLM) technology to build intricate metal parts. Fitted with dual 500 W fiber lasers, this powerhouse is adept at creating components as large as 325 x 325 x 400 mm from a variety of metals, including aluminum, stainless steel, titanium, and more. This positions the HBD 350 as a critical asset for sectors ranging from aerospace to medical industries, enabling innovation in product development and manufacturing.

The Unique Edge of the HBD 350

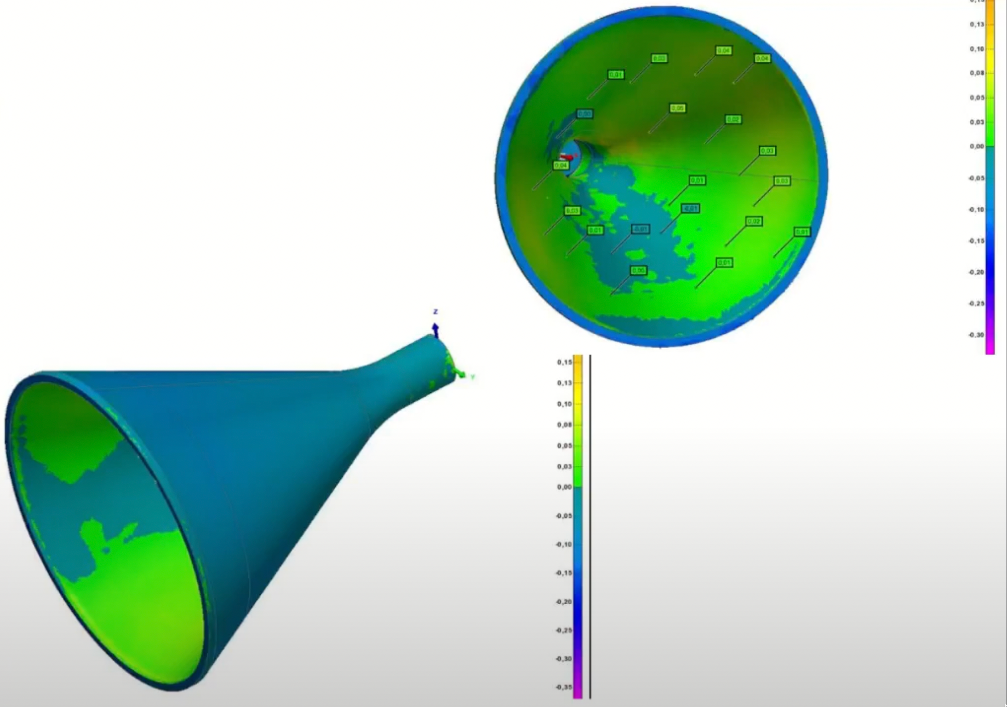

“The HBD-350 stands as the manufacturer’s flagship product, distinguished by its remarkable efficiency, large build volume, and high precision,” said Egor Driagin, Business Development Officer and Co-Founder of Top 3D Shop. “For instance, we have 3D printed several funnels using molybdenum-based powders and examined them with a metrology 3D scanner. The outcomes demonstrate that the printed model deviates only by 10–50 microns from the original 3D model, which is an excellent result for the university’s applications.”

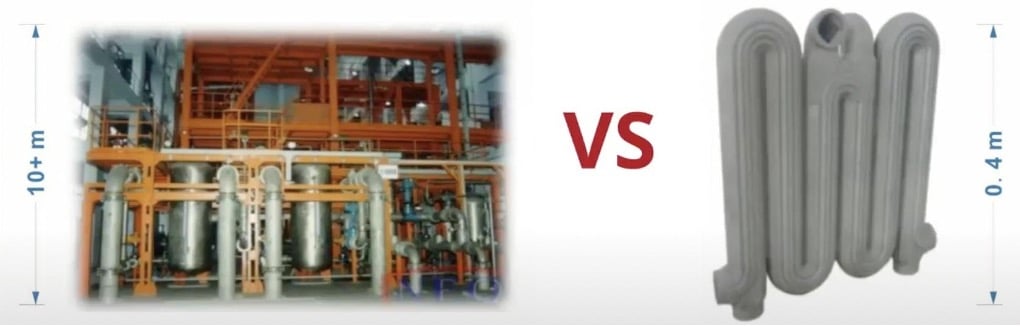

The build volume of 325 x 325 x 400 mm allows use of the HBD 350 not only for research and development, but industrial applications. A striking example is a reimagined nuclear reactor heat exchanger, which, thanks to the HBD 350, has been compacted from a towering 10 m to a mere 400 mm. This dramatic redesign results in a heat exchanger that is over 90% lighter and smaller, reduces production costs by more than half, and vastly improves energy efficiency.

Relevance and Advantages of Metal 3D Printing

The adoption of the HBD 350 carries implications far beyond the confines of the university. In terms of process, waste reduction, flexibility, lead times, material usage, and cost, the SLM 3D printing process marks a substantial improvement over traditional manufacturing methods.

This is particularly evident in the aerospace sector, where the precision and efficiency of 3D printed components have already been validated in rigorous testing environments.

“As a university, we plan to harness the capabilities of our new 3D printer to test innovative designs developed by the Department of Transport and Mechanical Engineering, and we are particularly excited about our new capabilities to produce complex geometries not achievable with traditional manufacturing methods,” said Savinkin Vitaly Vladimirovich, Head of Chair, Department of Transport and Mechanical Engineering at Kozybayev University

Educational Impacts and Advantages for Students

For students at the Kozybayev University, the HBD 350 is a gateway to experiential learning, rapid prototyping, and cross-disciplinary collaboration. The machine offers a practical demonstration of sustainable manufacturing, reducing material waste, and energy consumption. It also equips students with in-demand skills for the evolving labor market, fostering innovation and entrepreneurship.

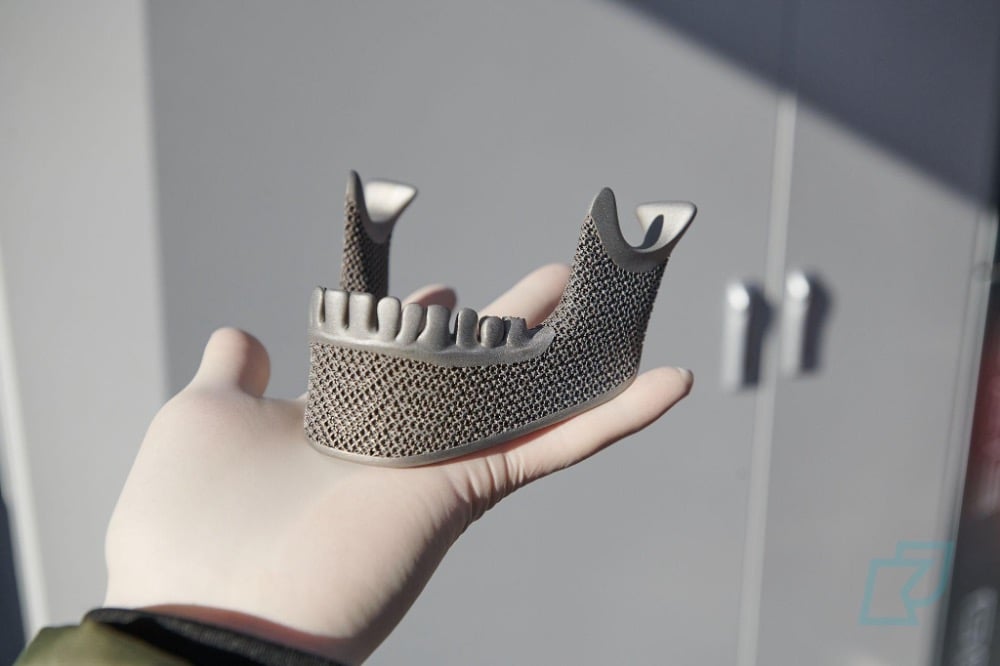

Broader Adoption in Kazakhstan

The installation of the HBD 350 at the Kozybayev University is the first SLM metal 3D printer deployed in Kazakhstan in an educational setting. The only other enterprise to leverage SLM 3D printing is the JSC NC “Kazakhstan Gharysh Sapary”, which is using SLM 3D printing to produce affordable titanium medical implants.

Partnerships in Progress

Top 3D Shop is the global value-added reseller and systems integrator of HBD, including regions of the USA and Kazakhstan.

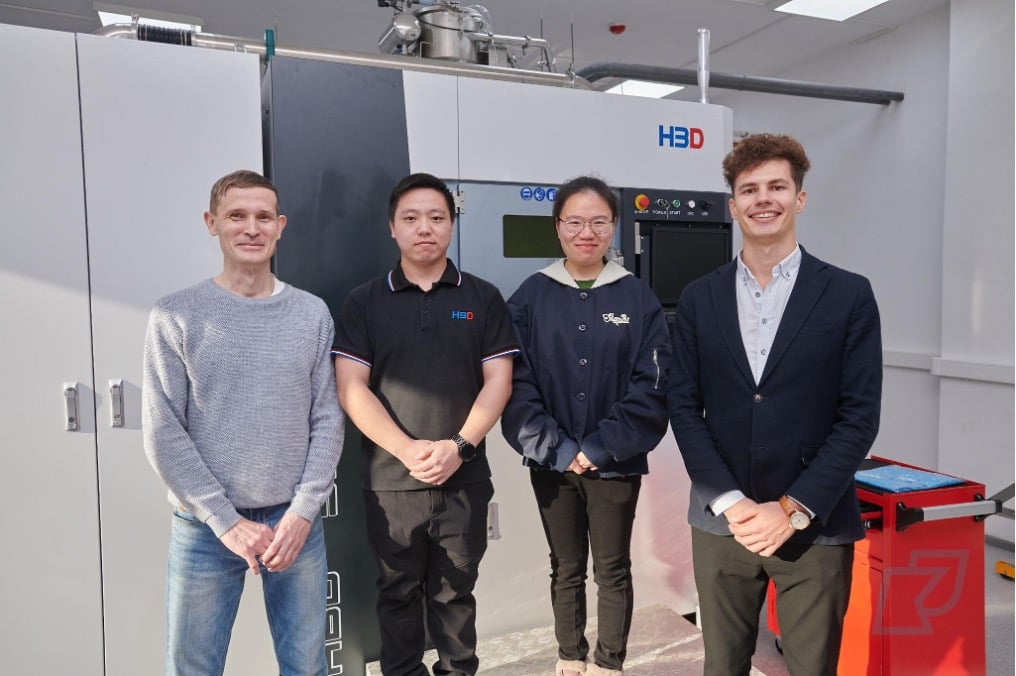

“The Top 3D Shop team excelled not just in delivering the HBD 350 printer, but also in their comprehensive training and setup support at our university. Their experts, along with HBD engineers, devoted two weeks to thoroughly commission the equipment and train our staff, guaranteeing proficiency in the system’s operation, maintenance, and software use,” Vladimirovich said “This thorough preparation culminated in our successful certification by HBD, affirming our proficiency and enabling us to certify others in this cutting-edge technology – a testament to Top 3D Shop’s exceptional partnership.”

The deployment of the HBD 350 at Kozybayev University marks a significant milestone in the field of additive manufacturing education, and is set to propel Kazakhstan into a new era of industrial innovation and academic excellence.