As professional 3D printers get more sophisticated, they actually get easier to use. Businesses want equipment that will boost their productivity, not saddle them with new technology to master. Today, 3D printing parts and tools can be as easy as pushing one button. Designing the parts, however, hasn’t simplified much, but that’s changing.

One company, Trinckle, a Berlin-based software start-up, makes a product for automating design in additive manufacturing. It just closed its Series A financing round of nearly $3 million (€3 million). With the fresh capital, Trinckle plans to expand its technology, strengthen its team, and roll out the software solution on a broader scale.

“By significantly reducing the entry barriers to design creation and allowing recurring design tasks to be fully automated on-demand, trinckle can give the whole additive manufacturing technology a decisive boost,” says Kerstin Herzog, managing director of the HZG Group, which is the lead investor in the latest financing round.

Trinckle says its Paramate software targets a central problem of additive manufacturing: every application – regardless of the industry – is associated with a high manual design effort. So far, this construction or design work can expertise in computer aided design programs.

“Users without CAD know-how can configure product designs via Trinckle’s cloud platform, while experienced designers can achieve significant leaps in efficiency in their work routines,” says Florian Reichle, co-founder and managing director of Trinckle.

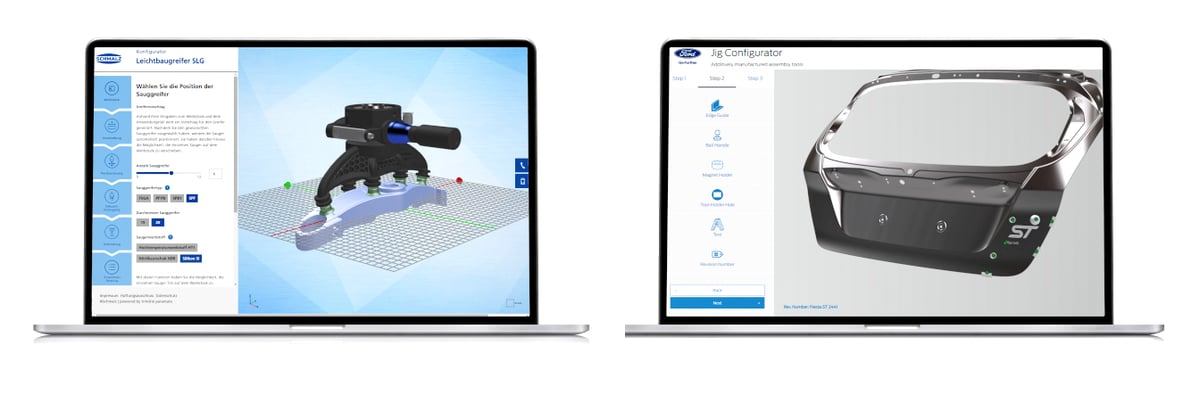

By not reinventing the wheel for every part, Paramate users start with customizable templates for products in various industries. Typical areas of application are medical products tailored to patients such as 3D printed orthoses, prostheses or dental applications; components in robotics and automation; jigs, stencils, and gauges for components for industrial manufacturing; along with lifestyle products. The Paramate architecture enables the combination of algorithm-driven CAD with intuitive and interactive configuration interfaces. The modular components can be tailored and orchestrated for your application.

“Many additive manufacturing business models are becoming economically viable for the first time due to the drastic cost reduction in the design process,” says Riechle. “Especially in terms of production aids, fixtures and tools, there is enormous potential for companies to make savings.”

Today, Trinckle’s solutions are already in use at manufacturing companies worldwide, including Ford, Volkswagen, Audi Sport, Airbus Helicopters, Phoenix Contact, Schmalz and Deutsche Bahn.

With its new investment, the HZG Group brings in not only capital but also entrepreneurial and technical expertise in additive manufacturing to manage the targeted company growth and to drive market penetration. The HZG Group founded Concept Laser in 2000, which was later acquired by GE for nearly $600 million.

License: The text of "Trinckle 3D Design Software Secures $3 Million Investment" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.