Considering the massive amount of plastic that is used in modern society, it’s critical to the environment that we recycle as much as possible. But, what if there was a way to use this plastic waste to develop something as awesome as a large-scale kinetic Tyrannosaurus Rex structure?

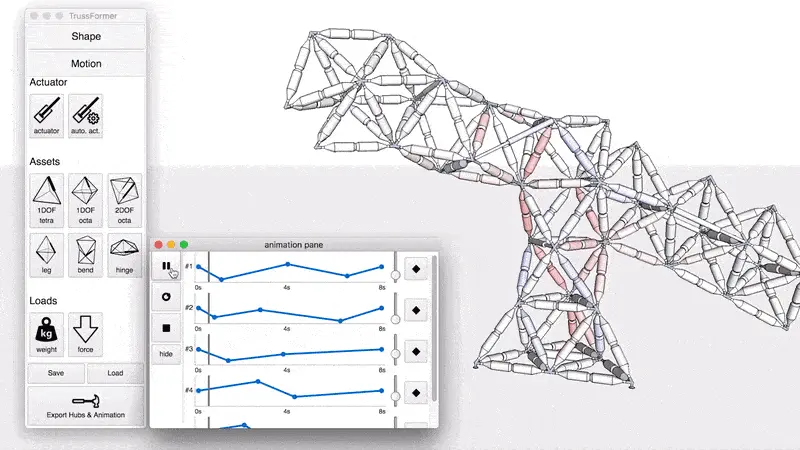

The scientists at the Hasso Plattner Institute in Germany have made this plastic Jurassic world possible with TrussFormer, an integrated end-to-end software solution that allows users to design and 3D print large-scale kinetic structures using plastic bottles.

TrussFormer is the next iteration of a previously developed software called TrussFab, a system that enabled users to design structures made from plastic bottles and 3D printed connectors. TrussFab essentially takes a 3D model and turns it into a weight-bearing structure that is optimized for plastic bottles and 3D printed connectors. It also figures out how many plastic bottles you’d need to build the structure with and generates custom plastic connectors for the entire design.

With TrussFormer, it works similarly in that it also uses 3D printed connectors and PET bottles to construct complex structures. The difference is that the resulting structures are kinetic, which means they can be set in motion and deal with dynamic forces. As you can see in the video below, the research team has already come up with some terrifying results…

TrussFormer Generates Large-Scale Kinetic Structures That Come to Life

In order to set the large-scale structures in motion, the software utilizes linear actuators and an underlying hinge system. This hinge system consists of custom connectors that can be 3D printed on your standard desktop printer.

The resulting structures are mechanically sound and can withstand dynamic forces that result from movement. To prove this, the scientists have developed multiple examples, one of which is a 4m-tall animatronics dinosaur that can move with 5 degrees of freedom.

Better yet, developing such structures on TrussFormer doesn’t require the user to be a knowledgeable designer or engineer. The scientists have focused on making the software accessible to non-expert users who are interested in designing their own kinetic creatures.

The design process begins in the program’s editor where the user will create a static design. The next step is to add movement to this structure using either automated placement, placing assets, or manual placement. A virtual simulation is generated to test the motion that is integrated into the structure, showing a color-coded depiction of where compression and tension will take place.

The TrussFormer software also generates an animation sequence to check whether or not the structure will hold up against inertia. If the model is unable to withstand this and breaks, the software will allow users to repair it by reducing the speed or motion. Finally, the algorithm will determine the placement and configuration of the hinges and their exact dimensions, preparing the auto-generated connectors for 3D printing.

In addition to producing these magnificent structures, TrussFormer will also export its animation patterns as Arduino code, which users can directly upload to a microcontroller. With TrussFormer doing all of the nitty gritty work, the most challenging aspect of creating your own 4m tall T-Rex will be sourcing enough plastic bottles to bring this dinosaur to life.

Want to find out more about this groundbreaking software system? Read the research team’s paper here.

License: The text of "TrussFormer Creates Large-Scale Kinetic Structures Made From Plastic Bottles and 3D Printed Connectors" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.