In a memo last week to senior Pentagon leadership, U.S. Secretary of Defense Pete Hegseth called for a transformation of military readiness that includes a major reform to the existing equipment acquisition strategy: the right to repair.

Contract manufacturers that supply the U.S. military with everything from night-vision goggles to aircraft often control the design rights, technical data, and manufacturing know-how needed to build, repair, or reproduce the item and its spare parts. Because contractors often fund some or all of the R&D, they then retain IP as a way to recoup investment.

However this can lead to a dependency on a single manufacturer for replacement parts, slower maintenance, limited field support, and higher costs.

To counter this, Hegseth has instructed the Secretary of the Army, Daniel P. Driscoll, to “seek to include right to repair provisions in all existing contracts and also ensure these provisions are included in all new contracts.”

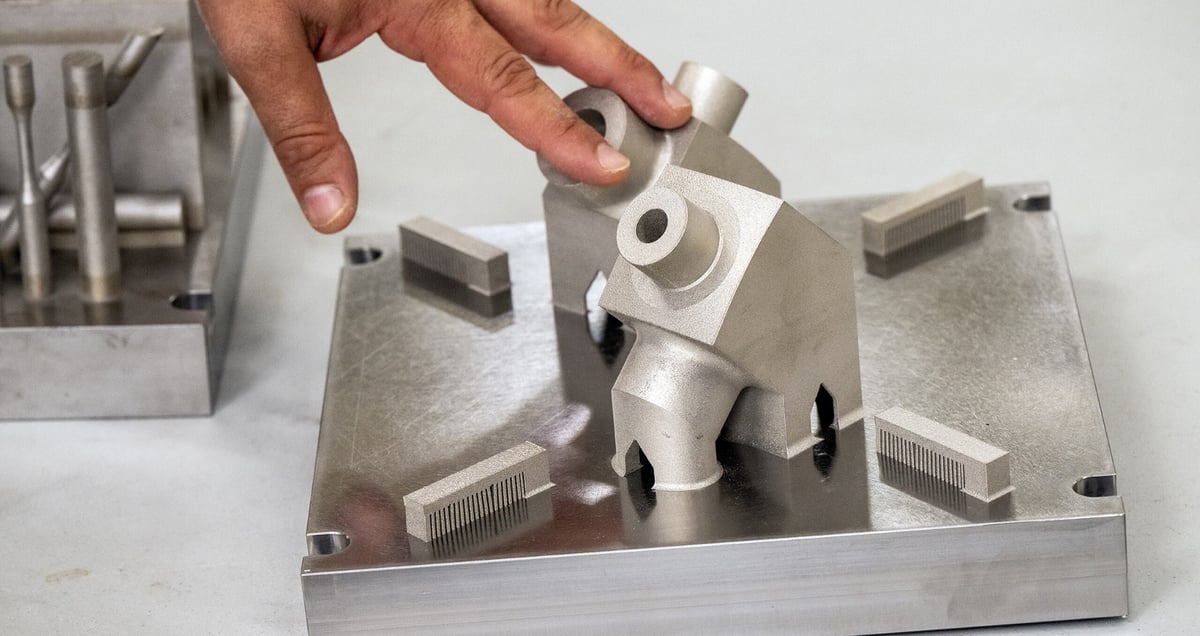

This major shift could be a green light for the military’s various additive manufacturing centers to ramp up production of legacy and spare parts without having to go through the original manufacturers.

There’s been strong focus since the beginning of the Trump administration on military readiness through advanced technology.

One program, underway for the past year s the Battle Damage Repair and Fabrication (BDRF) initiative to use 3D printing to rapidly restore battle-worn ground vehicles, cutting repair times and boosting operational efficiency. Although this program is designed to produce only temporary vehicle parts, the quality has reportedly outperformed original parts in testing, prompting discussions about the potential for this program to serve as a permanent secondary source of supply.

A recent study from Additive Manufacturing Research on military and defense spending on 3D printing forecasts a $2.6 billion market by 2030.

Additive manufacturing has been a game-changer in helping to create parts and equipment for DOD’s industrial base, according to the Department of Defense.

Last week, leaders from across the defense and manufacturing sectors came together in Danville, Virginia, for the fourth annual joint summit hosted by the Accelerated Training in Defense Manufacturing program and the U.S. Navy’s Additive Manufacturing Center of Excellence. Held at the Institute for Advanced Learning and Research (IALR), this year’s event, themed All Hands on Deck, focused on addressing workforce and manufacturing shortfalls in Navy shipbuilding and repair.

The summit highlighted the growth and momentum of the defense manufacturing program with its new 100,000-square-foot training center to graduate up to 1,000 students per year to meet challenges in shipbuilding and advanced manufacturing.

You May Also Like:

License: The text of "U.S. Army’s New Right-to-Repair Mandate Could Ignite Demand for 3D Printed Spare Parts" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.