Remember in CSI, when Gil Grissom and Catherine Willows would trace a photocopy back to a suspect’s house? Well, unlike some of their other techniques (cough enhancing images cough), it turns out that that’s actually plausible! At least, it is for 2D prints…

Now, thanks to a research team out of the University at Buffalo, NY, it’s also possible for 3D prints! Under the leadership of Wenyao Xu, an associate professor of computer science and engineering, the group has developed a 3D printer identification system that can physically link a 3D printed object to its source machine.

They tested their system, called PrinTracker, against 14 3D printers, 10 fused deposition modeling (FDM) devices and 4 stereolithography (SLA). Each machine was made to create five typical door keys, which were then analyzed for imperfections.

To begin, the team generated digital images of the keys using an inkjet scanner. Then, by applying multiple filters to the images, they were able to identify distinct variations. Interestingly, these corresponded to patterns that were similar within but not between sets of five keys. In other words, the printers were successfully shown to have unique “fingerprints”.

The fingerprints were identified using an algorithm that the team themselves developed. Their hope is that the technique could be applied to law enforcement, especially in the context of tracking illegally 3D printed objects like guns.

“3D printing has many wonderful uses, but it’s also a counterfeiter’s dream,” says Xu. “Even more concerning, it has the potential to make firearms more readily available to people who are not allowed to possess them.”

How To Spot a 3D Printer’s Fingerprint

Enthusiasts will be familiar with the additive manufacturing processes behind FDM and SLA. While one deposits molten plastic and the other cures photosensitive resin, both produce 3D objects one layer at a time.

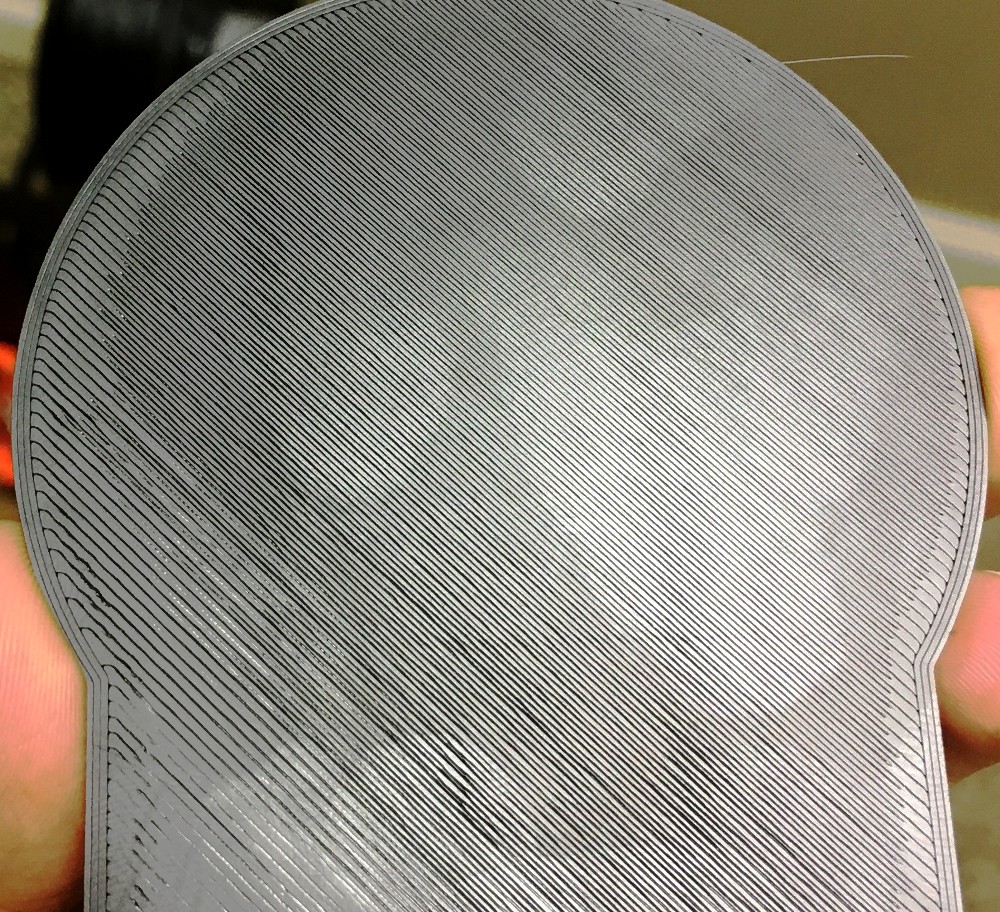

Ideally, the lines in each layer should be consistently and uniformly drawn. Unfortunately for those of us who like to print, that’s rarely the case. In FDM, for example, what normally happens is that tiny ripples form throughout each layer. Even the best prints can have wrinkles on the sub-millimeter level.

These imperfections, according to the group at UB, are unique for each printer. And that’s not hard to believe when you consider that they’re caused by things like the machine’s nozzle, frame stability, and stepper motors.

“3D printers are built to be the same,” says Xu, “but there are slight variations in their hardware created during the manufacturing process that lead to unique, inevitable and unchangeable patterns in every object they print.”

And that’s the key to PrinTracker: repetition. The aspects of a machine that cause it to produce imperfections one time are likely to do so every time. In this way, every 3D printer has a fingerprint.

The study will be presented tomorrow at the Conference on Computer and Communications Security (CCS) 2018, which is hosted by the Association for Computing Machinery (ACM). For more information on PinTracker, check out the team’s research paper or stay tuned for the conference proceedings.

Source: University at Buffalo News Center

License: The text of "UB Researchers Develop System to Identify 3D Printer Fingerprints" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.