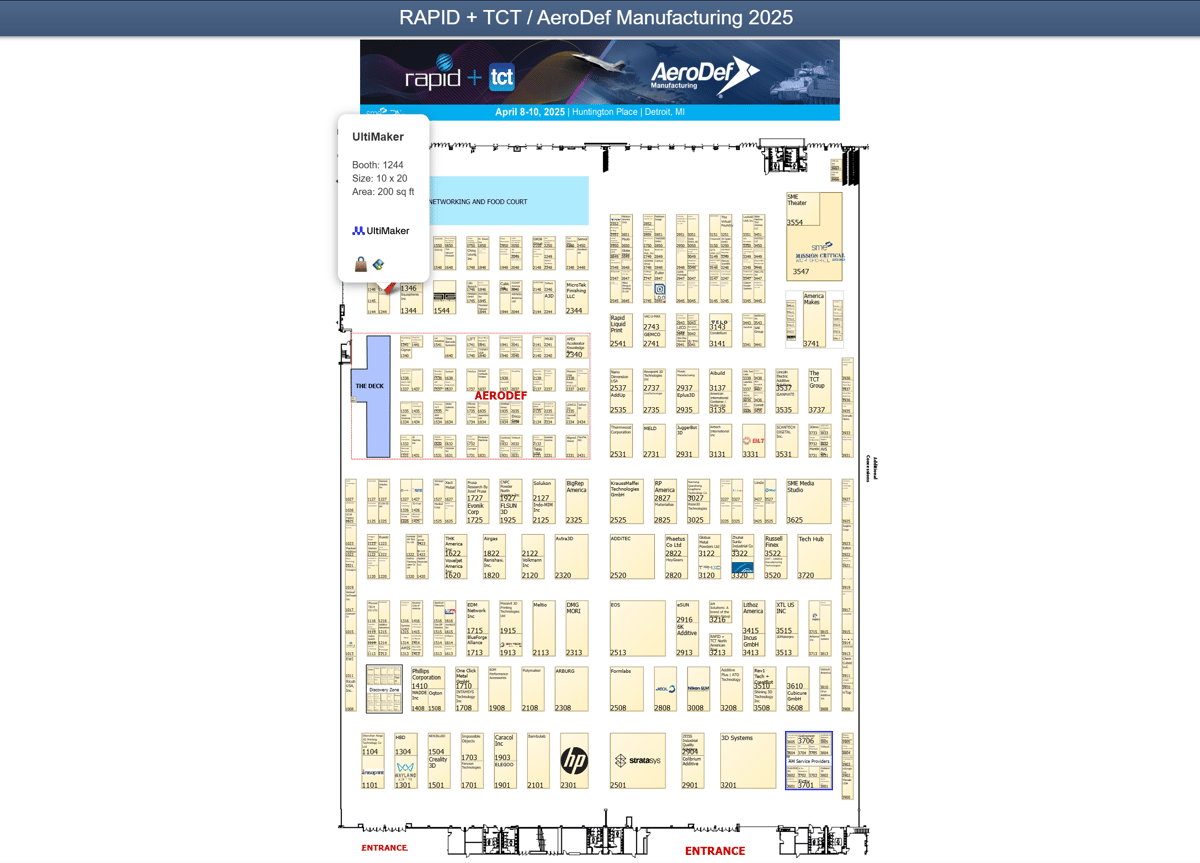

The UltiMaker booth (#1244) at Rapid + TCT 2025 will no doubt be decked out with the company’s many machines and materials, from the perennial favorite S5 to the industrial Factor 4 to the new nylon CF Slide filament. But the star of the show will be the new S8 with its upgrades in speed, precision, flexibility, and efficiency.

About two years ago, UltiMaker launched the S7, and, less than a year ago, the company took a new path in FDMs with the “light-industrial” Factor 4.

The S8 is not positioned as an upgrade or an improvement on either, according to UltiMaker, but a completely different chapter — even though from the outside it’s practically identical to the S7. Compared to the S7, the S8 offers four-times the speed, five-times the processing power, and improved part quality.

Although UltiMaker has never wanted to talk speed, preferring instead to talk about productivity, now they’re putting their money where their mouth is with a clear print speed of up to 500 mm/s and accelerations up to 50,000 mm/s2. This is equal to the Bambu Lab X1 Carbon in speed and betters it by 30,000 mm/s2 in acceleration.

Clearly, the core driver for UltiMaker was to make a faster printing machine without compromising its reputation for quality. This pursuit began with the “Cheetah motion planner” backed by a “newly developed electronics platform.”

Cheetah is the bit of programming that translates Gcode to printhead movement. One innovation here is that Cheetah is a “jerk-limited” motion planner, which means that you don’t experience any jumps in acceleration that can lead to bulging or blobs at sharp corners among other defects. Basically, the motion planner reacts on the fly to input from the system as it’s doing the job, rather than following prescribed movement instructions blindly.

“It’s a totally new way of calculating motion paths,” says Marc Uyttenboogaard, a mechanical engineer and the S8 product manager at UltiMaker. “We do have input shaping which is somewhat similar to Klipper, but jerk limited means that we cap the maximum change of acceleration which results in smooth motion with full control over motion path accuracy.”

At Rapid + TCT, UltiMaker is also debuting a new material that showcases the machine’s abilities. UltiMaker Nylon CF Slide, a nylon 612 CF copolymer offering wear resistance and temperature resistance of up to 180°C, the company says.

The S8 is compatible with 14 UltiMaker branded materials — from PLA and PETG to TPU 95A, PET-CF, PC, and nylon CF — and there are more than 300 other materials you’ll be able to use on the S8 with print profiles provided by the manufacturer downloadable via UltiMaker Marketplace.

For more on everything happening at Rapid + TCT, including new product launches and events, visit the All3DP Rapid + TCT Special Coverage.

License: The text of "UltiMaker at Rapid + TCT 2025: See the New S8 in Action" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.