A new generation of smart 3D printers is under development which will use artificial intelligence to oversee and optimize 3D printed parts. The US Navy’s Office of Naval Research (ONR), which is funding the ambitious project, has recently announced a two-year $5.8 million contract.

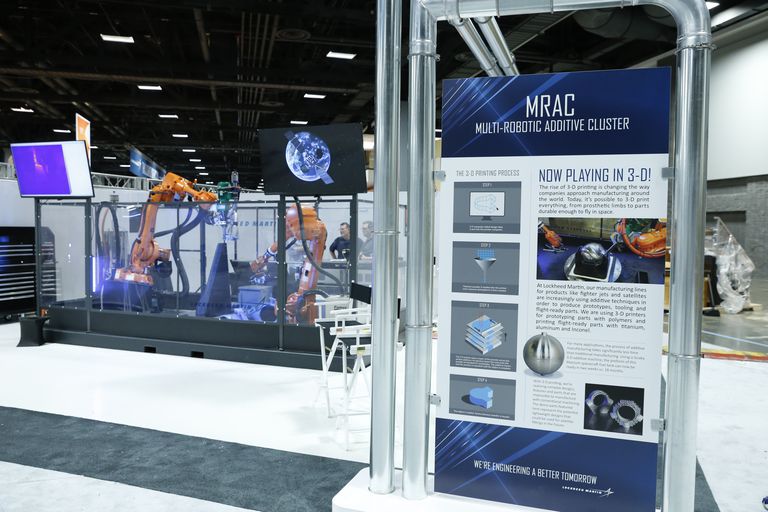

There are four partners working on this project, led by Lockheed Martin’s Advanced Technology Centre. The collective aim is to be able to create robots that can make independent decisions on how to optimize the production of complicated 3D printed parts.

Currently, 3D printing is useful in a huge number of industries, but still requires high levels of “babysitting” and constant monitoring to ensure success. This is the reason why the US Navy is researching how artificial intelligence can be applied to train robots to reduce this workload while still creating complex, high-quality parts.

Brian Griffith, Lockheed Martin’s project manager, said: “We will research ways machines can observe, learn and make decisions by themselves to make better parts that are more consistent, which is crucial as 3D printed parts become more and more common… Machines should monitor and make adjustments on their own during printing to ensure that they create the right material properties during production.”

Would You Trust Self-Determined 3D Printing Robots with Lasers?

The research project will specifically focus on customizing multi-axis robots that utilize high-powered laser beams to deposit certain materials. First, the team is focusing their experimentation on the commonly used titanium alloy Ti-6AI-4V.

The researchers are developing new software models and sensor modifications to result in better 3D printed parts. But, central to this contract is “verified analysis and integration into a 3D printing robotic system”. In other words, the 3D printers will be capable of making proper adjustments on their own by using machine learning algorithms. The 3D printing robots will learn from each other and train themselves, continuously optimizing the process.

According to Lockheed Martin, there is a lot of time and resources wasted when creating complex parts. For instance, consider the time that technicians need to spend testing quality after a print is complete, or the practice of designing parts that must compensate for inherently weaker sections.

Hopefully, when this two-year contract is complete, the researchers will have an AI robot that can monitor, control and optimize structures based on a previously verified analysis. These refined 3D printers could be critically useful for a variety of people, such as those who are in remote areas far away from major supply chains.

Zach Loftus, Lockheed Martin Fellow for additive manufacturing, said: “When you can trust a robotic system to make a quality part, that opens the door to who can build usable parts and where you build them. Think about sustainment and how a maintainer can print a replacement part at sea, or a mechanic print a replacement part for a truck deep in the desert. This takes 3D printing to the next, big step of deployment.”

Source: Press Release

License: The text of "US Navy and Lockheed Martin Are Building AI-Driven 3D Printing Robots" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.