Volkswagen (VW) Group is using Artificial Intelligence (AI) and 3D printing produce car components which can be more complex and light-weight. The Germany-based company recently showcased its new process at its Innovation and Engineering Center California (IECC).

On display was its first vehicle to have parts designed using AI and manufactured with a 3D printer, the company’s modern electric version of a retrofitted 1962 Microbus.

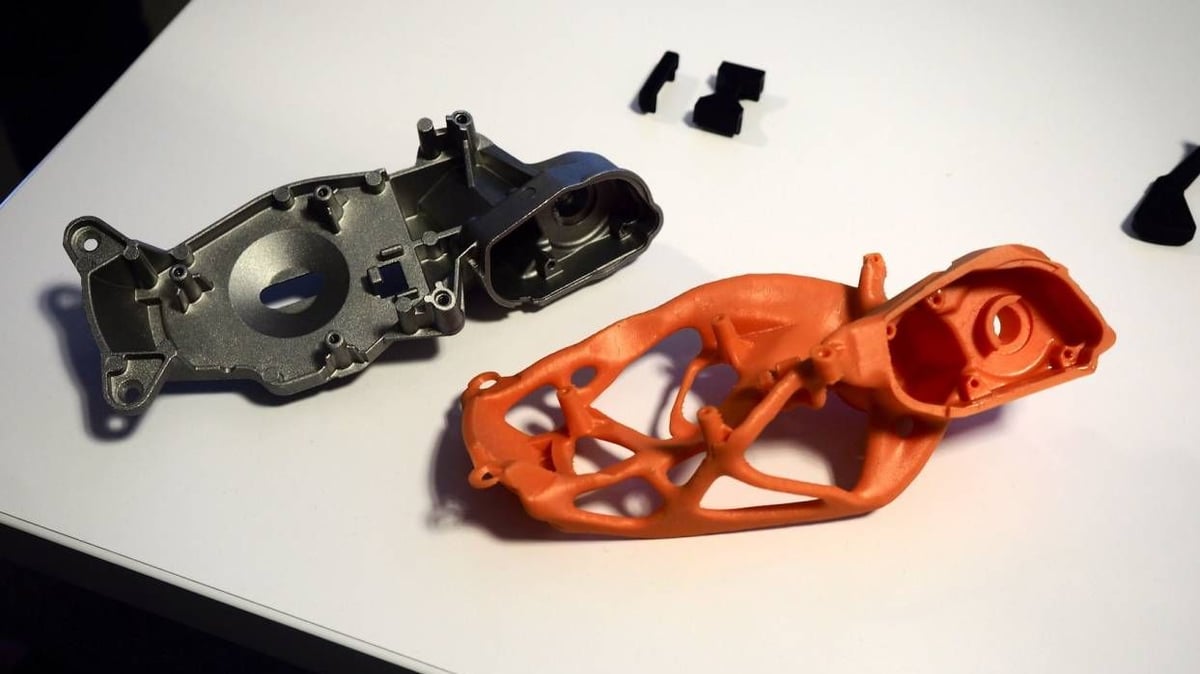

The vehicle has many bright orange components which make it easy to spot the Generatively Designed shapes. These parts include the steering wheel, side mirror supports, and even the wheels.

By training AI, engineers can use the Generative Design program to focus on their priorities and the technology meets these criteria, producing a lightweight yet structurally sound design.

From Straight Lines to Curved Shapes

Interestingly, it seems that VW’s AI produced parts look a lot less modern chic – with straight edges and hard lines – and a lot more like tree roots.

To produce these complex shapes, 3D printing is the obvious answer. But, as all vehicles have thousands of components, the team are working on figuring out which can be effectively replaced with 3D printing. To do this, they’re also relying on AI to flag potential parts.

In the future, VW has big plans to use technology to create a closed-loop recycling system in which it can use plastics from old components to create new ones. Not only does this save fuel it also results in less waste which is good news for the planet.

Although a fully 3D printed car is not yet possible, VW has proven that using AI and 3D printing in car design results in more flexible designs, lightweight parts and financial gains.

Source: Slash Gear

License: The text of "Volkswagen uses AI and 3D Printing to Produce Lightweight Car Parts" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.