To support the continuous adaptation of 3D printing technology across several industries, XYZ Printing has set its sights on making affordable machines capable of industrial performance. The manufacturer recently brought the MfgPro236 xS and MfgPro230 xS, its two flagship Selective Laser Sintering Selective Laser Sintering (SLS) 3D printers, to the professional market.

Working towards the goal of making pricey powdered materials more affordable and accessible to customers, XYZ Printing has partnered up with AM Polymers, the German 3D printing material supplier, to develop a new batch of SLS 3D printing materials. The latest addition to XYZ Printing’s growing assortment includes a flexible and sturdy TPU material and PP01 Polypropylene, an FDA-approved food-grade material.

Produced by AM Polymers, the two new materials will be added to the growing line of SLS 3D printing materials offered by XYZ Printing, which already includes PA6, Ultrasint PA11, sPro12W, and sProTPU. Combining these material offerings with XYZ Printing’s SLS 3D printer line, customers now have access to affordable and professional-grade machines capable of producing highly functional and accurate parts.

By adding a new TPU and PP01 Polypropylene into the mix, XYZ Printing is expanding its presence in the professional market and introducing materials that will satisfy professionals and businesses that are leveraging SLS 3D printing for prototyping and end-use production.

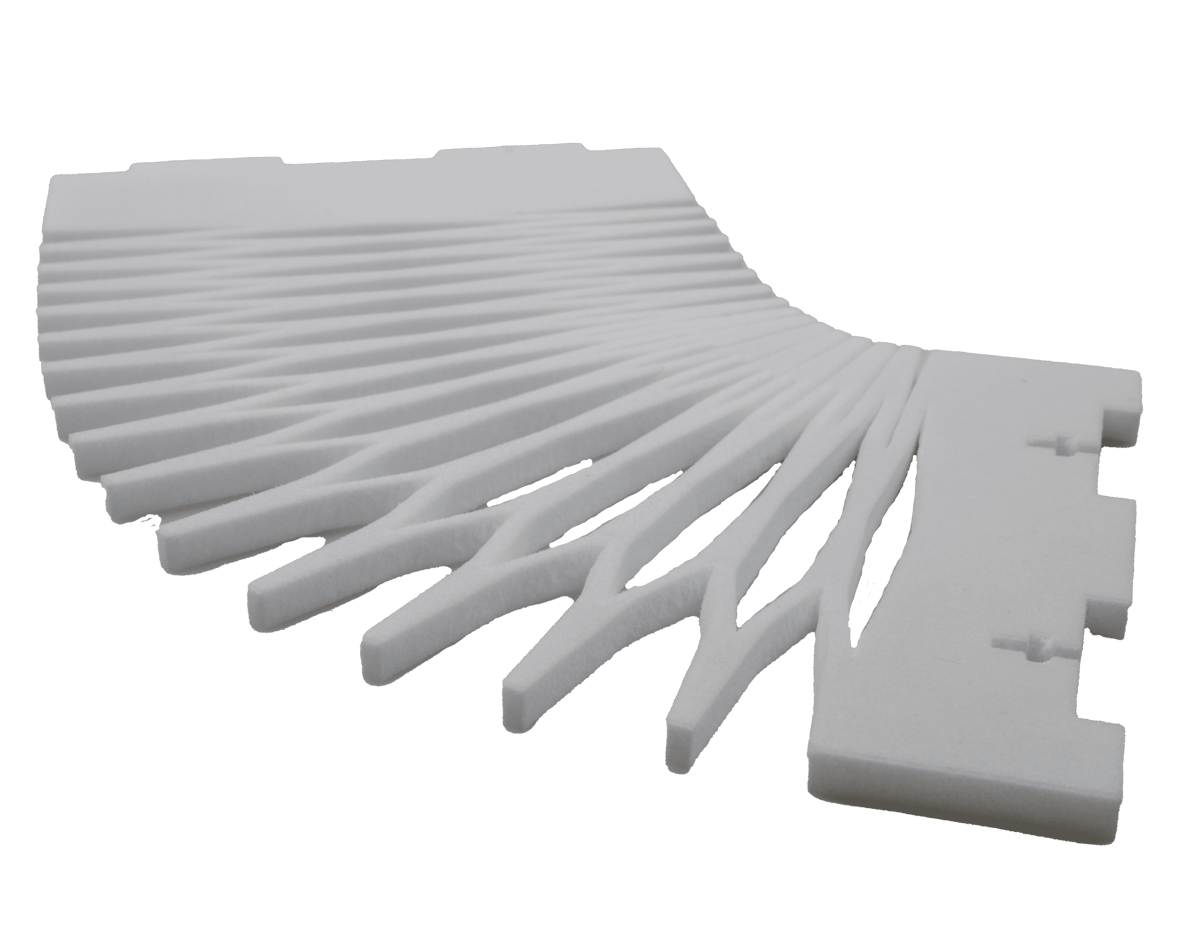

AM Polymers TPU: Soft, Strong, and Durable

Known for its flexibility and strong mechanical properties, TPU has long been a stable material for commercial endeavors of all sorts, from the medical sector to shoe industry. In collaboration with AM Polymers, XYZ Printing has created a new and improved TPU that is both highly durable and offers excellent elongation.

AM Polymers PB01 TPU was engineered for high performance, providing tremendous elasticity, resistance to wear and fatigue, and exceptional detail resolution. The powder formula ensures a 20% powder refresh rate, while also ensuring easy flowing and no smoke during the printing process. Here’s more detail on the mechanical properties of AM Polymers PB01 TPU:

- Hardness shore: 75 A

- Tensile strength: 8 MPa

- Young’s modulus: 55 MPa

- Elongation at break: 550%

This TPU material is useful for several applications, ideal for producing the following:

- Sports protection equipment

- Midsoles

- Designer shoes

- Orthopedic insoles

- Car interior components

- Lattice engineering

- Tools, grippers and pipes

- Medical

- Robotics

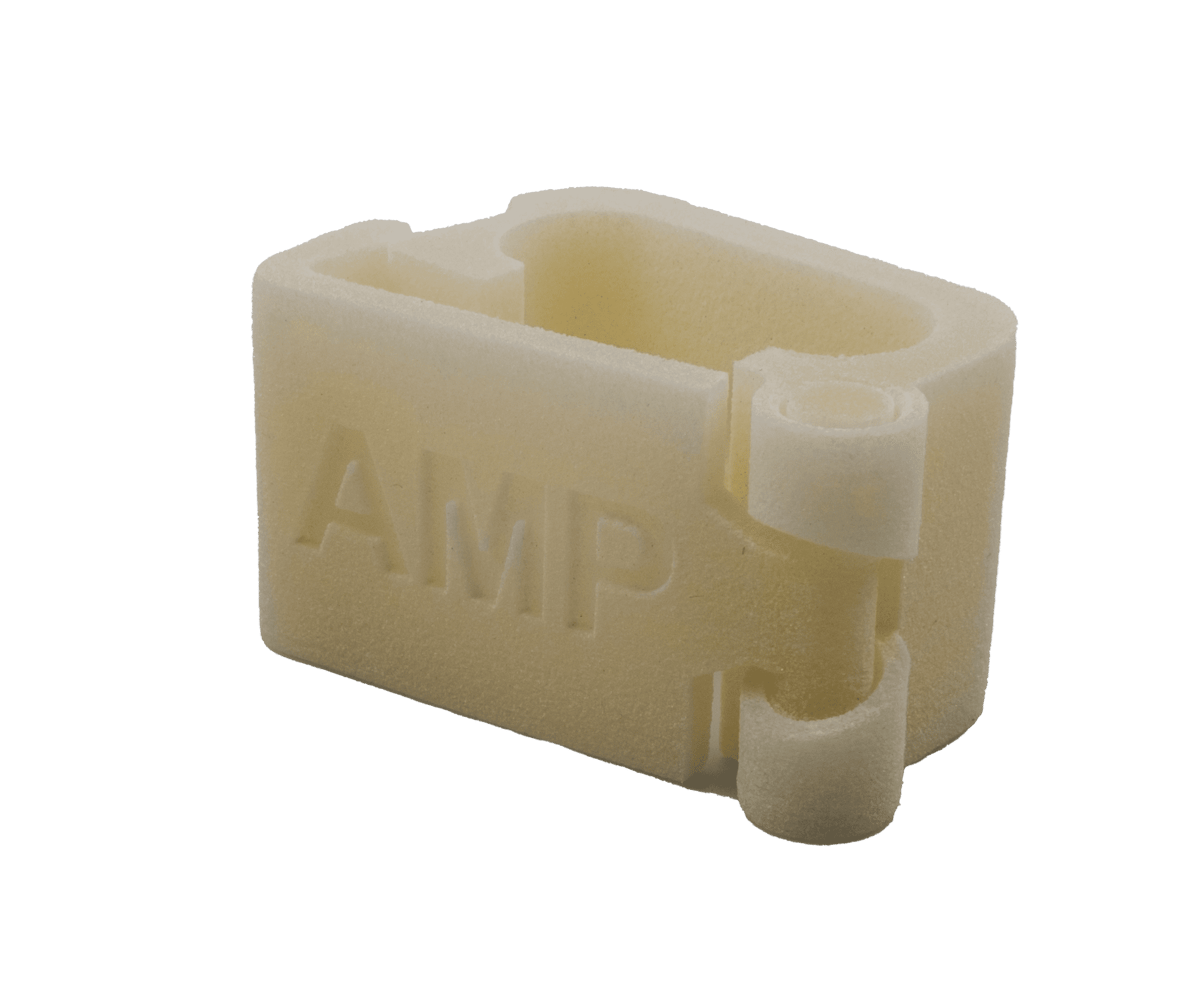

Polypropylene PP01: FDA-Approved Food-Safe Material

Despite the many recent advancements that have taken place in the 3D printing industry, there remains a need for materials that are food-safe. In collaboration with XYZ Printing, AM Polymers developed an FDA-approved food-grade PP01 Polypropylene material for SLS 3D printing.

According to XYZ Printing, PP01 Polypropylene may be safely used in articles that contact food, except for packing or holding food while it’s being cooked or heated up. The material offers low warpage, easy post-processing, and excellent detail resolution. Compared to other Polypropylene on the market, this powder is incredibly cost-efficient and provides a 50% powder refresh rate.

The mechanical specs of AM Polymers PP01 Polypropylene are:

- Tensile strength: 20 MPa

- Young’s modulus: 820 MPa

- Elongation at break: 30%

While the FDA stamp of approval is the primary characteristic of this material, PP01 Polypropylene can be leveraged for more than the production of food-grade parts. It can be used for several applications, including:

- Automotive

- Medical

- Packaging

- Chemicals

- Toys

- Robotics

- Snap fits

- Sports equipment

- Education

All in all, the expansion of SLS materials showcases XYZ Printing’s dedication to making commercial 3D printing more accessible and affordable for pro users and small businesses.

Visit XYZ Printing to learn more about its professional 3D printing offering, including its new array of materials, and request a quote for a MfgPro236 xS or MfgPro230 xS SLS 3D printer.