Asya Ilgün is a designer and researcher at the University of Graz whose EU-funded Ph.D. project, “Hiveopolis,” is a fascinating study in creating mycelium bio-hybrid beehives, or “beesnest enclosures”. By integrating sensors and smart algorithms into beehives, the project aims to boost hive health and productivity.

Recently, Ilgün shared an Instructables project about her research into creating the fungal honey farms that serves as a digestible guide for anyone interested in sustainable beekeeping.

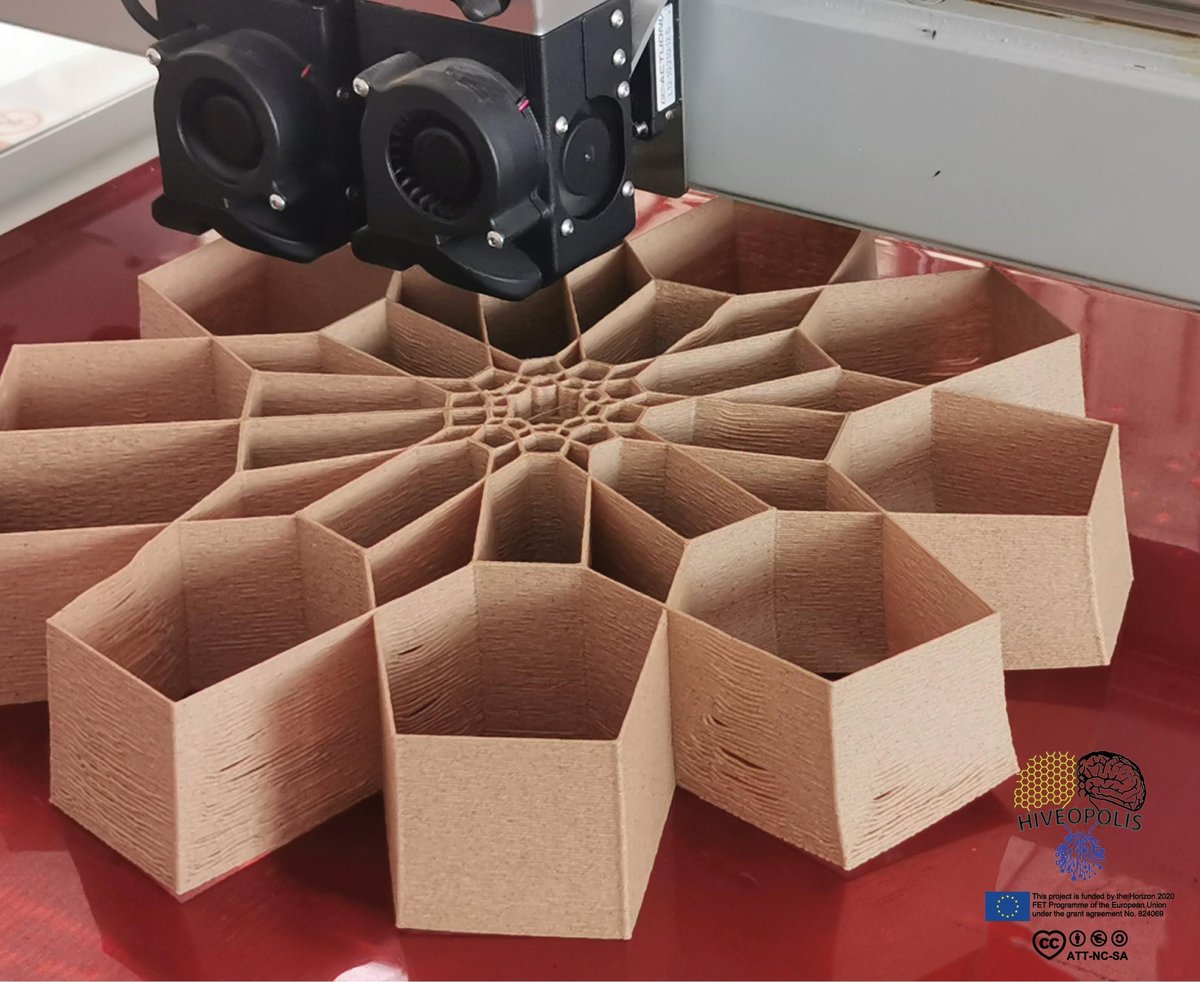

Mycelium beehives are made from the vegetative part of a fungus. This material is biodegradable and helps maintain a stable temperature inside the hive, crucial for bee health. A desktop 3D printer can craft molds or smaller components into which the mycelium can grow.

Creating a mycelium beehive yourself requires a 3D printer, mycelium spawn, common substrates (like flax, wheat straw, and beech wood particles), and basic tools such as buckets, cups, and a mixing tool.

Though Ilgün produced the study’s beehive molds on a large-format BigRep 3D printer, the Instructables project specifies that “you can start experimenting with smaller sizes using Prusa printers, i.e., Prusai3 MK2 since you can find the specific initial and end codes for the gCode in the grasshopper script.”

Ilgün’s mycelium beehives aren’t the first time bee colonies and 3D printing have intersected. Over in Australia, HiveHaven took a stab at 3D printing beehives with an environmentally friendly HPDE material derived from recycled milk bottles to tackle issues like pests and overheating. Unfortunately, the cost of 3D printing each hive with the material — about $900 — was a major roadblock compared to traditional wooden hives. The project was paused in 2016 the team looked for more budget-friendly options.

More recently, José Francisco Arteaga Alarcón, a master’s student at the Autonomous University of Chapingo in Mexico, garnered attention with his own 3D printed hives. Using resin 3D printing, Alarcón replicated the hexagonal structures of hives, sparing bees the laborious task of building their habitat as would be required in a typical bee box or beehive. Instead, Bees can focus on honey production, which not only reduces their fatigue but also avoids common issues like heat, noise, and space problems found in conventional hives. A less stressful environment means healthier, happier bees.

If you’re interested in taking on Ilgün’s project and creating a mycelium beehive yourself, be prepared for a time-intensive process, taking approximately a month. Unlike 3D printed hives that take 8 to 12 hours of printing time, mycelium beehives require a more patient, natural approach while the fungus grows.

With innovative projects like Hiveopolis and advancements from students like Alarcón, the future of beekeeping looks a-buzz with 3D printing potential. Whether you’re a seasoned beekeeper or a curious DIYer, creating a mycelium beehive offers a rewarding way to support bees and the environment at large. Share your experiences with our community and let’s keep pushing the boundaries of what’s possible for 3D printing in beekeeping.

Find more 3D printing projects:

License: The text of "You Can 3D Print Your Own ‘Bio-Hybrid’ Beehives Thanks to This Research" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

Stay Informed, Save Big, Make More

Stay Informed, Save Big, Make More