3D Printer That Delivers

Zmorph just unveiled a new website along with a new brand image and a new printer in their product portfolio called the Zmorph Fab. The rebranding will be followed by a new marketing strategy that places the company in a professional market sector, and allows further growth in the industrial area.

The new brand look shows the evolution of Zmorph since its founding in 2012. The company is shifting toward a professional market segment. The new brand image features a modern, technical appearance that goes with the new Zmorph core built around brand essence: 3D printer that delivers.

The company’s mission is to learn, improve, and deliver exactly what customers need. Zmorph’s portfolio will grow with new reliable and high-quality 3D printers in the following years.

“It’s the single most important moment for Zmorph brand since its founding back in 2012,” says Bartosz Lanc, ZMorph’s CMO. “We evolved from a dynamic startup into a reliable brand and partner for professionals in over 120 countries. The rebranding will enable Zmorph to further expand into the global market, accomplish global growth objectives and strengthen the professional image. Today, more than ever Zmorph is becoming more competitive and offering more capabilities to our customers and business partners.”

Zmorph has had rapid growth in recent years. In 2020, the company acquired 3D Printers, owner of the HBOT brand. HBOT’s experience in industrial-grade 3D printer manufacturing enables Zmorph to create a synergy in R&D and prepared the company to move into a professional market segment. The fusion results in a stronger engineering team working on expanding Zmorph’s product portfolio with new 3D printers and solutions for modern manufacturing.

Additionally, Zmorph established partnerships with well-known distributors, such as Profound3D and Matterhackers in the US; 3D Criar in Brazil; 3D Prima, Hava3D, and RS Components in Europe; Maxwell, Beets 3D, and Maha Chem in Asia; and Torstar in Australia among others. The company gained 5 million PLN (around $1.3 million) in a financing round at the beginning of 2020, and is talking with new investors, both are further signs of the company’s growth.

The Industrial Zmorph i500

In the first quarter of 2021 the company plans to present Zmorph i500, the workbench 3D printer for professionals that includes a huge work area, single and dual extrusion 3D printing, and competitive quality-to-price ratio. Stay tuned for more news to be announced soon.

“We have had a very good year despite COVID,” says Maciej Nawrocki, Zmorph’s CEO. “I do not want to say that we are where we want to be, but our growth is secured as firm as never before and our strategy is solid, reliable, and backed up by investors who trust in it as strong as we do in Zmorph.”

“The 3D printing market is maturing, moving towards professional and industrial applications,” Nawrocki continues. “Anticipating this direction two years ago thanks to our smart marketing guys and customer-sensitive sales, we have created a product roadmap that addresses the trend. Next year is the year of launching our new products.

“Our proposal for the professional and industrial market will be a strong hit in the segment. We take lots of experience coming from HBOT F300, an industrial printer which was successful in Poland, and our workhorse Zmorph VX, now Fab, that paved the way to the most demanding customers in the consumer segment. We have acquired the industrial product technology and know-how together with the acquisition of 3D Printers company last year. Our joint R&Ds, I mean Zmorph and HBOT, are working now on the product which addresses professional expectations in terms of reliability, repeatability, and reproducibility, as well as serviceability.”

Zmorph has plans to deliver a full industrial ecosystem including the machine, a redeveloped slicer software and on-machine firmware, plus the company is in the process of acquiring a renowned producer of quality filaments. These moves will secure a predictable performance from the new Zmorph i500.

“We work together with our great distributors and resellers to place it on the market in the first half of 2021,” says Nawrocki. “This will be a global launch where our current rebranding and wide marketing campaign is to support our partners in efficient reach to our end customers who we are sure will benefit from the value we bring with our new Zmorph i500.”

Zmorph Fab, the Most Advanced and Easiest to Use, All-in-One 3D Printer

The new Zmorph Fab, the company’s most advanced and easy-to-use all-in-one desktop 3D printer is the successor to the well-known versatile ZMorph VX. Zmorph Fab features an interchangeable toolhead system that allows 3D printing, CNC milling, laser engraving, and cutting with the same device.

“Zmorph Fab is made to be easy-to-use and reliable,” says Eliza Wróbel, Product Manager at Zmorph. “The latter is crucial for a product that operates three different workflows and it’s meant to work 24/7. The new Zmorph Fab’s features are based on feed back from customers and business partners making it the most advanced yet easy-to-use all-in-one 3D printer on the market. With new features like HEPA fumes filter Zmorph Fab is a great addition to modern classrooms, FabLabs, workshops, and design labs.”

The Brand New 3D Printing Single Extruder Toolhead

The all-new single extruder toolhead delivers faster prints with best quality. The new extruder gains motion sensors for filament detection. It’s now easier to feed the filament, and the machine will stop once it runs out of material and wait for the user to feed the next spool of filament. The redesigned cooling fan improves the air flow, which allows faster overhangs in 3D printing.

The Advanced CNC Environment

Zmorph Fab features an expanded CNC workflow. The new CNC worktable was designed to allow easy and very stable material mounting (and is open for custom designs). It features a refurbished Voxelizer with CAM-standard workflow for CNC procedures with STEP operations and the ability to change the tool within one G-code, plus path visualization.

The Safety Measures Air Filtration and Smart Toolheads

Due to the demand for educational standards and user safety, the new Zmorph Fab is equipped with an optional HEPA carbon filtration system. The air filtration process makes it safer and cleaner to work with materials producing semi-toxic fumes and particles, such as ABS, or fumes created during laser engraving.

Zmorph Fab detects which toolhead is installed with the SMART Toolheads System. The toolhead changing is now easier than ever before, which cuts time of workflow switching.

Last but not least, the new machine is equipped with industry grade electronics, meaning that it is a desktop 3D printer, but with a heart of a professional industrial machine.

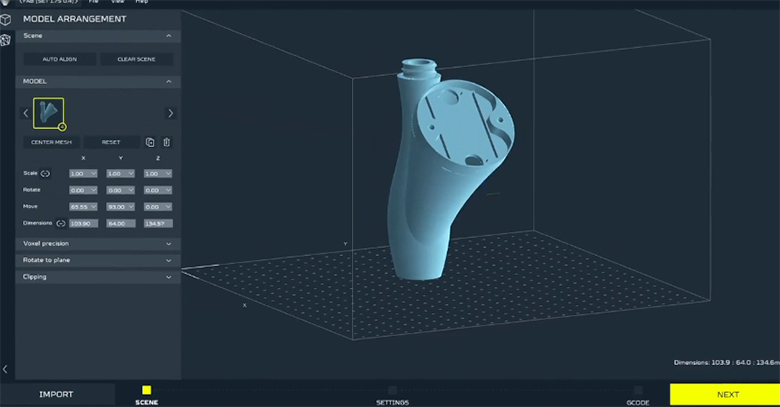

The New Voxelizer

To celebrate the release of Zmorph Fab, the company is also updating the slicing software. The new version of Voxelizer is ready for the refurbished CNC workflow, features more presets for 3D printing, and underwent rebranding to reflect the current brand image

Technical specification

Technology: FFF/FDM, CNC mill, laser engraver/cutter, thick paste syringe

Build volume: 250 x 235 x 165 mm (toolhead dependent)

Layer resolution: 0.05-0.4 mm (depending on the nozzle diameter)

Material diameter: 1.75, 3.00 mm

Nozzle diameter: 0.3 – 0.6 mm

Work area leveling method: automatic, manual

Connectivity: USB, Ethernet, SD card

Materials: PLA, ABS, PET, Nylon, PVA, HIPS, ASA, TPE, PP, PC, PMMA, PC/ABS

Maximum extruder temperature: 250° C

Maximum platform temperature: 115° C

Filter type: HEPA/Carbon

Software bundle: Voxelizer

Supported operating systems: Windows (7/10 64 bit) and macOS (10.13 or later).

Full specification available at the manufacturer’s website.

Pricing

Zmorph Fab is available in two bundles. The All-in-One set includes Single Extruder Toolhead 1.75, CNC Milling Toolhead and Laser Toolhead and costs 3999 USD. The 3D Printer option is a cheaper variant for people and companies interested in the 3D printing toolhead only, and it costs 2959 USD. There’s an extra option of making a custom set.

You can order Zmorph Fab via Zmorph online store or via one of the authorized resellers worldwide beginning today.

License: The text of "Zmorph Unveils Rebranding & New 3D Printers" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.