ACEO, part of Wacker Chemie, is revealing a method to 3D print multiple materials at the same time at this year’s Formnext trade show

ACEO is a team which is part of Wacker Chemie AG, one of Germany’s biggest chemical companies. At this year’s Formnext in Frankfurt, Germany, the team has revealed they’ll be presenting a new way of 3D printing silicone for professional use.

The latest update of their technology works by simultaneously printing more than one silicone at once. The team is calling this a milestone in 3D printing silicones, as this could mean printing silicone parts that were previously unthinkable.

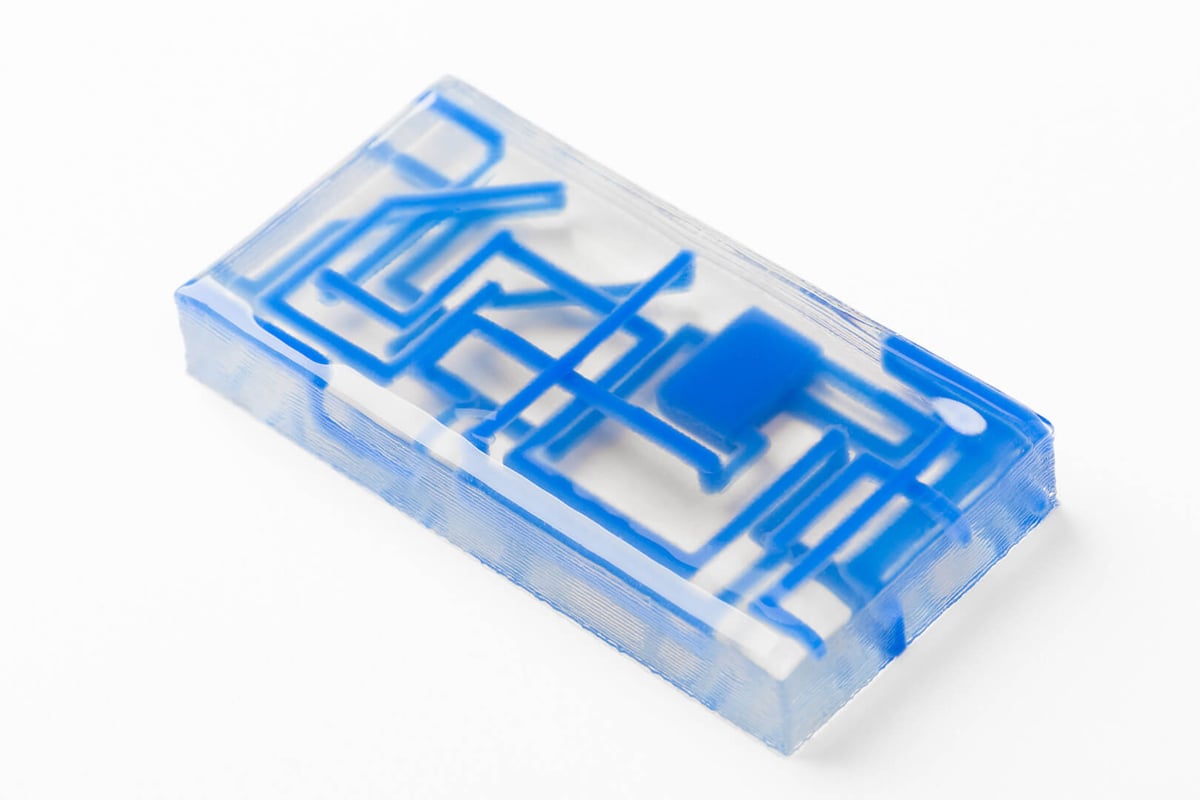

As the company puts it, by 3D printing with silicones, it becomes possible to create small product series, bio-models, and functional prototypes more easily than before. Better yet, 3D printing silicone makes creating inner structures of parts possible.

“Silicones of different colors, hardness or even chemical or physical properties can now be placed independently from each other at any given point throughout the process, which allows sharp as well as merging gradients,” explains Dr. Bernd Pachaly, Head of Project 3D Printing. “The result: even more freedom of design in the construction of objects with multiple materials 3D printed in one single process, in particular, soft and hard segments.”

Drop on Demand: ACEO’s 3D Printing Silicone Technology

ACEO’s technology relies on a “drop-on-demand” principle. This means single drops of silicone are printed and built up, flowing together smoothly. After one layer is finished, it is cured with UV light before the process begins again.

However, it’s also possible to create complicated structures as a support material is printed and can be removed after the print is finished. Simply wash the finished print with water and finally, to achieve mechanical properties, the object should be post-cured at elevated temperatures.

It’s been a busy couple of years for ACEO. When the technology was first revealed by ACEO back in 2016, their silicones were the first elastomers which could be 3D printed and maintain their properties.

Soon after, the company launched a web shop for 3D printing with silicones. As well as this, All3DP recently covered the company’s opening of their Open Print Lab in Burghausen.

If you’re at formnext in Frankfurt between November 14th and 17th this year, visit the ACEO booth. The development will be presented at the Wacker Chemie AG booth: C-18, hall 3.1.

However, if you want to find out more and won’t be in Germany this November, simply visit the ACEO website.

Source: Press Release

License: The text of "ACEO to Reveal Silicone Multi-material 3D Printing at Formnext 2017" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.