Californian researcher unveiled a new way of imprinting sound qualities on objects. Their “acoustic voxel system” can be manipulated like Lego to create all kinds of sounds.

Earplugs and earmuffs are great for blocking out unwanted sounds. Unfortunately, they can be tough to deal with as they may also block out important sounds like road traffic or sirens. What if scientists could create earmuffs that block out specific sounds and let others through? These researchers have combined 3D printing and algorithms to create a system that could, in the future, do just that.

Researchers from Columbia University, MIT, and Disney Research wanted to create objects with very specific acoustic properties. In the past, this would have been hugely difficult. According to said project lead Changxi Zheng, that’s about to change.

“With 3D printers today, geometric complexity is no longer a barrier. Even complex shapes can be fabricated with very little effort. So the question is: can we use complex shapes to improve acoustic properties of products?”

Acoustic Voxel System: Like Lego For Audio

All3DP readers may be reminded of the Zoolophone, a project also headed by Changxi Zheng, wherein researchers were able to make different animal-shaped keys for a metallophone. Zheng has taken what he learned a step further.

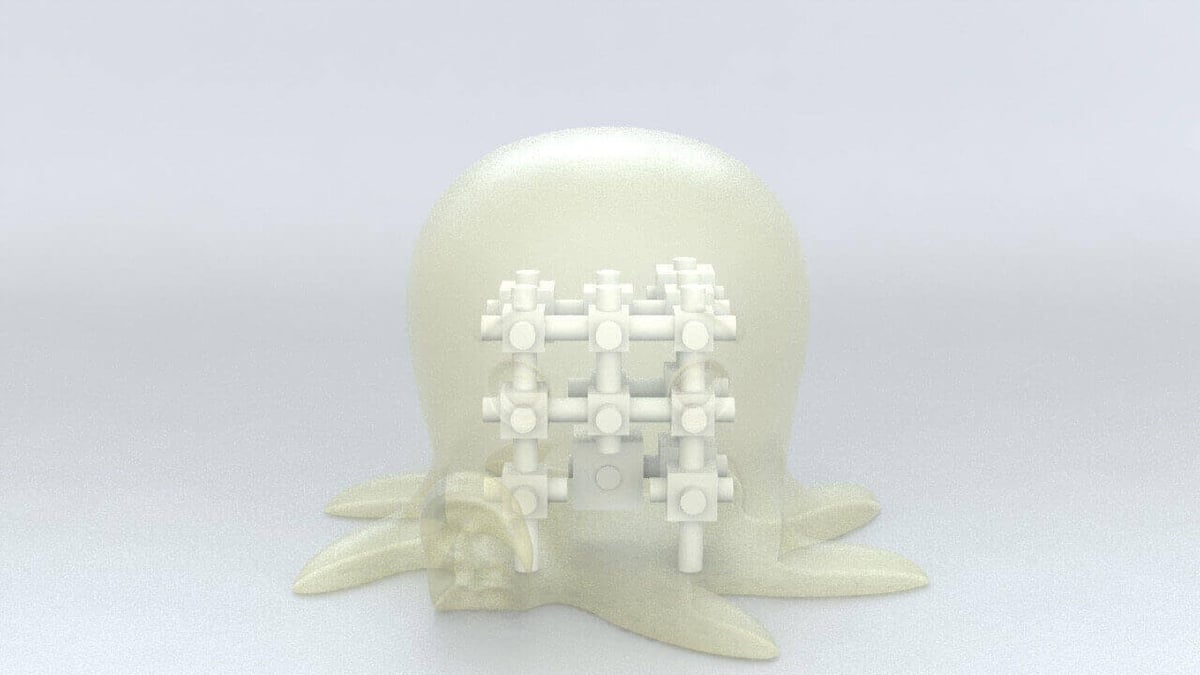

Zheng and his team have created “acoustic voxel”, tiny chambers through which sound enters and exits. These chambers are interconnectable and may vary in size and geometry. They can give an object a distinctive sound, as you would do with an equalizer. The acoustic voxel can be compounded almost like Legos to create an adjustable and complex system that yield different acoustic results.

You can see a network of these voxels depicted below.

Much like a Lego design, the researchers also need a sort of a “map” to correctly assemble the pieces. This comes in the form of an algorithm.

“Our algorithm enables new designs of noise mufflers, hearing aids, wind instruments, and more – we can now make them in any shape we want, even a 3D-printed toy hippopotamus that sounds like a trumpet.”

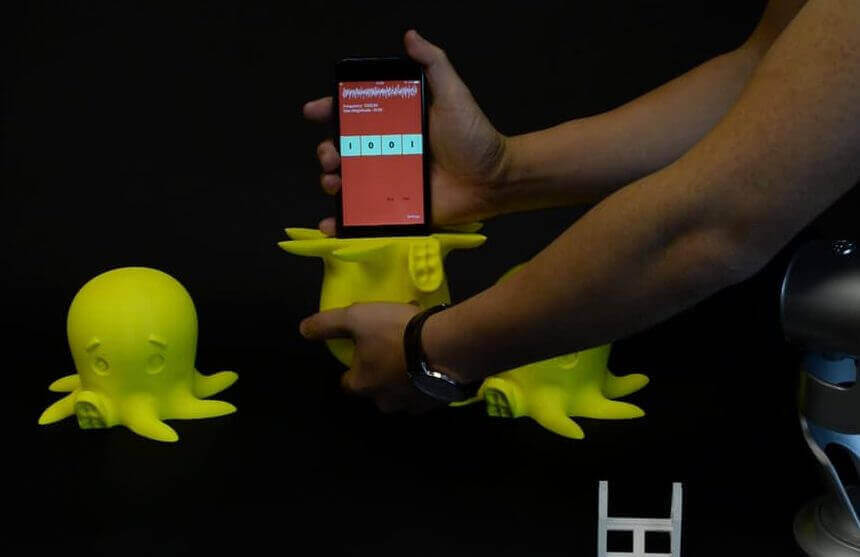

The resulting voxel system can be put it nearly any object. This means five identical looking objects could be filled with five entirely different audio systems – an interesting approach for everyone building instruments.

From DRM to Better Mufflers: The Many Possibilities of Acoustic Voxel

As these 3D printed acoustic voxel structures result in a distinct frequency spectrum, this could even be used for a sort of digital rights management not only for songs but also of instruments and objects. Zheng adds,

“We also have proposed a very intriguing new way to use acoustic filters: we can use our acoustic voxels as acoustic tags, unique to each piece we 3D print and encode information in them. This is similar to QR codes or RFIDs, and opens the door to encoding product and copyright information in 3D printing.”

So, what else can acoustic voxels do for you? Think of motorcycle earmuffs that could minimize traffic and wind noise but allow the sounds of honking cars to get through. In future, ultrasound waves are the next target for the project.

The team will be presenting their paper on July 27th at the SIGGRAPH 2016 conference. The project’s only remaining proposition includes using these voxels as acoustic tags, much like a QR code or RFID. Could this open the door to wiring copyright information into 3D printed objects?

License: The text of "“Acoustic Voxel” Give Sound to 3D Printed Objects" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.