Aeronautics company, Airbus, has installed a titanium 3D printed bracket for the engine pylon on its in-series production Airbus A350 XWB.

With the advancement of 3D printing, more and more companies are using the technology to develop end-use parts for their designs. This is especially true for the aerospace industry, where every gram counts. The latest company to use metal 3D printing for an important production part is Airbus.

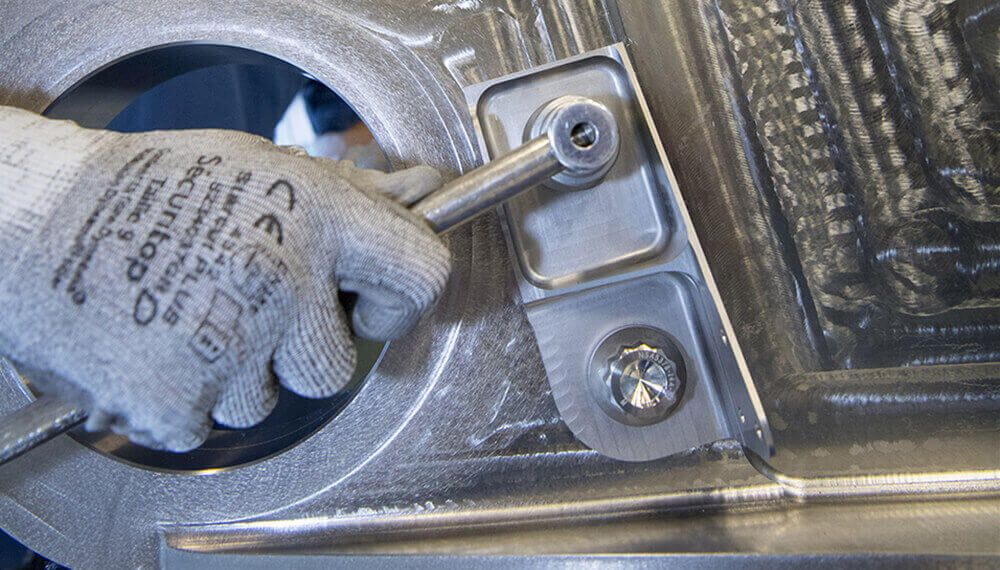

The European aeronautics company revealed that they have completed the installation of a titanium 3D printed bracket on an in-series production A350 XWB. The 3D printed part is a bracket which is part of the aircraft pylon. This is the junction section between the wings and engines.

Although the 3D printed part is relatively small, it brings with it big changes. In fact, the company hopes that it’s the first step towards more complex, 3D printed parts.

If this part does well, we could see more 3D prints in production aircraft next time you’re flying with commercial airlines which use the company’s planes, such as Finnair or Qatar Airways.

Airbus Continues to Grow with 3D Printing

In fact, the company has been using 3D printing for some time now. For example, both for its jets and even for creating 3D printed concept aircraft, Thor. The company explains in a statement:

“Additive-laying manufacturing ‘grows’ products from fine base material powder-such as aluminium, titanium, stainless steel and plastics-by adding thin layers of material in incremental stages, which enables complex components to be produced directly from computer-aided design…. 3D printed parts are already flying on some of Airbus A320neo and A350 XWB test aircraft. These include metal printed cabin brackets and bleed pipes.”

However, Airbus adds that they would like to integrate more intricate parts. But, due to the quality which can be provided by 3D printing, it’s a great choice for the aeronautics leader.

As we regularly see with 3D printed prototyping and components, the savings can be great. All the while, companies are also creating complex parts in a simpler process compared to traditional methods.

If you want to find out more about Airbus, you can visit their website, here. Or, read more about how 3D printing is being used in aviation on All3DP.

Source: Aviation Tribune

License: The text of "Airbus Production A350 Aircraft has First 3D Printed Titanium Bracket Installed" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.