Algorithm developed by engineering researchers at University of Michigan allows desktop 3D printers to boost speed without impacting quality.

A team of engineering researchers at the University of Michigan have written an algorithm that can reduce the time required to 3D print an object by half.

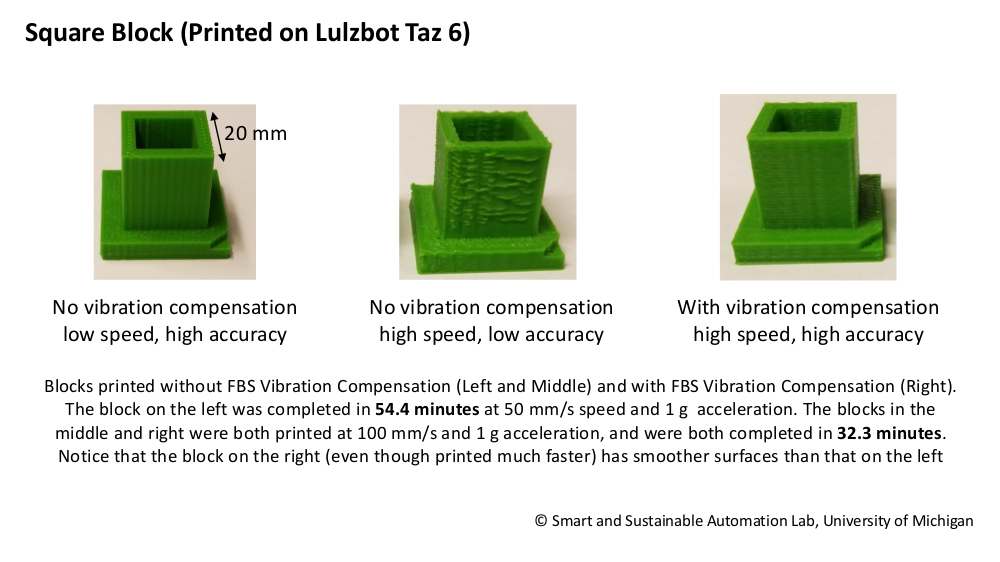

The solution is specifically applicable to desktop fused deposition modelling (FDM) machines. As the print head of a 3D printer deposits layers of molten plastic, its moving parts cause vibrations. This can lead to errors when fabricating an object; the faster a print head moves, the more the machine vibrates and the greater the chances of a printing error.

“Armed with knowledge of the printer’s dynamic behavior, the program anticipates when the printer may vibrate excessively and adjusts its motions accordingly,” says Chinedum Okwudire, an associate professor of mechanical engineering who directs the University’s Smart and Sustainable Automation Research Lab.

The findings were published in the academic journal Mechatronics in a paper titled: “A limited-preview filtered B-spline approach to tracking control – With application to vibration-induced error compensation of a 3D printer.” The consumer printers used in the research were a HICTOP

3D Printing Algorithm Addresses Need for Speed

In a news release from the University of Michigan, Okwudire pointed at recent comments by the CEO of XYZprinting, Simon Shen, who argues that slow print speeds are preventing 3D printing from finding wider adoption.

“We’re just waiting for the next evolution of the technology,” Shen told TechCrunch last year. “If they can do it much faster, more precise and easier, that will bring more people to 3D printers. Not waiting for four to six hours for a print, but 40 to 60 minutes.”

“Armed with knowledge of the printer’s dynamic behavior, the program anticipates when the printer may vibrate excessively and adjusts its motions accordingly.”

The software is not only applicable to consumer 3D printers, but also some large industrial-grade printers. Okwudire reckons they can integrate the algorithm with printer firmware in the future.

“Eventually, one of the places we would want to see the algorithm applied is in the firmware — the software that runs on the printer itself,” he says. “That way, it will be integrated with the printers, regardless of the size.”

Many folks in the 3D printing industry will be very glad to see widespread adoption of this algorithm. While we wait, check out the software in action in the video below.

Source: University of Michigan

License: The text of "New Algorithm Cuts 3D Printing Times by Half" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.