“Computational thermoforming” may sound like boring technobabble, but it’s actually a cool method to add color and detail to physical objects.

Yet again the team at Disney Research have come up with a fantastic application using 3D printing — this time in tandam with a vacuum former — to provide striking detail and color to a physical object.

According to their research paper: “We propose a method to fabricate textured 3D models using thermoforming. Differently from industrial techniques, which target mass production of a specific shape, we propose a combined hardware and software solution to manufacture customized, unique objects.”

So what does that mean in plain English?

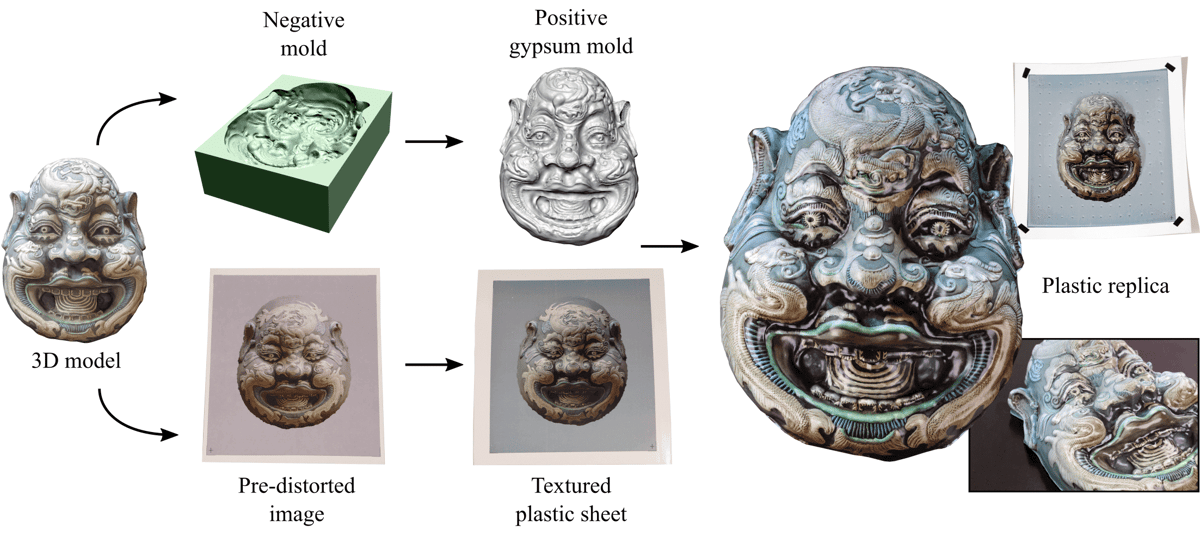

First, you use a 3D printer to make a negative mold, and then fill it with gypsum powder to make a cast object from the mold.

Next, using a vacuum former, you shrink a layer of plastic coating over the top of the object to add a layer of detail. Incredible, right?

Check out the video to see computational thermoforming in action. And bring popcorn, because this is amazing:

Computational Thermoforming Looks Awesome

The real trick to computational thermoforming is the computer simulation that performs this process over and over, to create an image that is deformed in just the right way so that it looks normal when the plastic sheet is stretched out over the object.

Disney Research are confident that this technique will have many applications, such as rapid prototyping in full color at a cheaper cost and more quickly than existing additive manufacturing techniques.

In the video you can see toy cars, computer peripherals, or scale replicas of geographical topography. In fact, there’s every chance that computational thermoforming could supplant the need for 3D printing in color altogether.

What do you think of this innovative new idea? Let us know in the comments.

(Source: Disney Research)

License: The text of "Disney Research Develops “Computational Thermoforming”" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.