Researchers from Queen Mary University of London have developed a 3D bioprinting method that enables the creation of biological structures from cells and molecules that are commonly found in natural tissues.

NASA is launching the Omics in Space project, using 3D printing to develop tools to study omics aboard the ISS. These tools would allow astronauts to analyze biological samples and also assess how the space environment impacts their health.

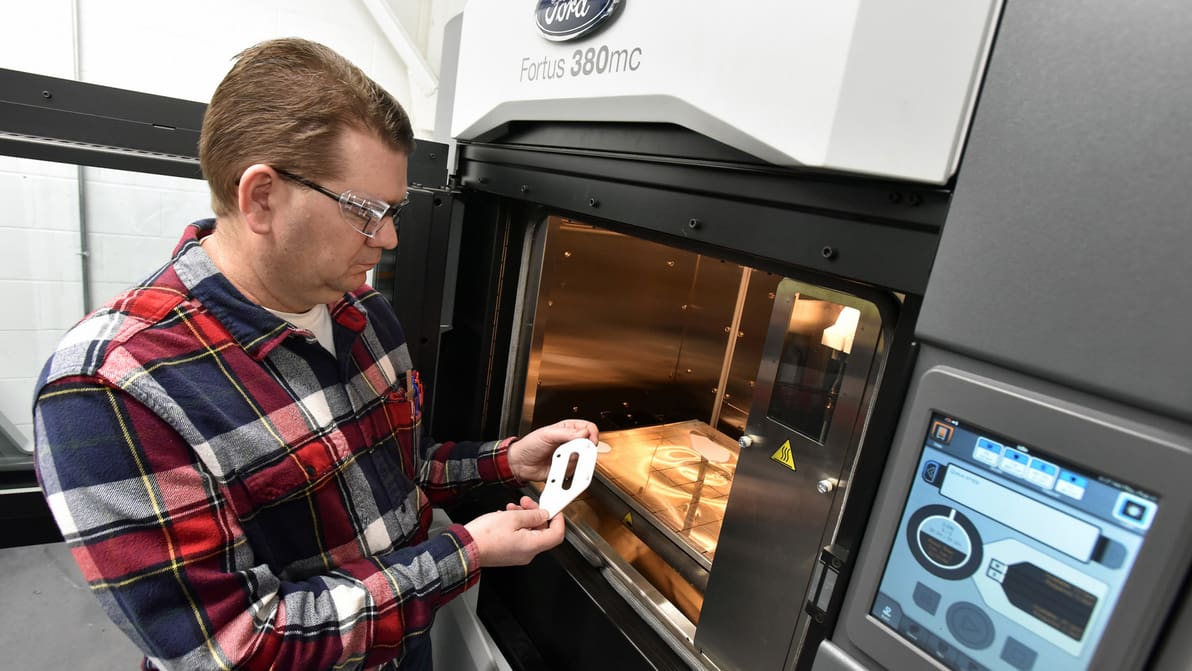

Following good sales performance of its Expedition and Navigator SUV lines, Ford has stepped up production by adding a Stratasys 3D printer and 400 new robots to its production plant.

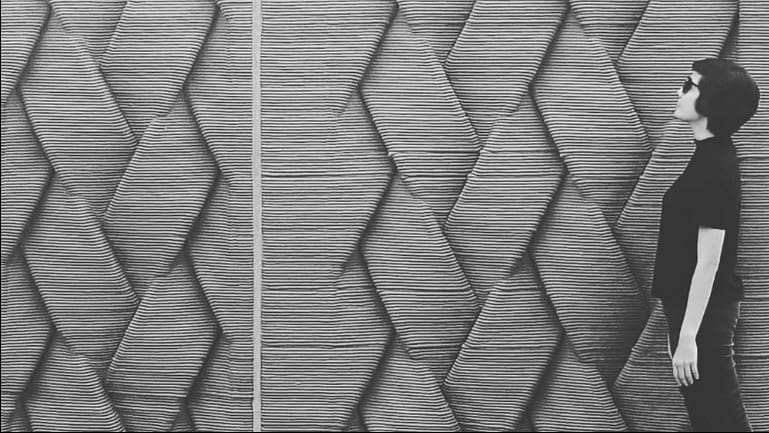

The Thai cement manufacturer SCG has developed a special concrete material to 3D print structures with a unique weaving pattern. The 3D printed concrete technique offers improved structural integrity and a stunning aesthetic.

For this year's Winter Olympics in South Korea, the US Luge team worked with Stratasys to create custom sleds using additive manufacturing technologies.

3D printing with a Zortrax M200 has made it easier for NASA engineers to create vital tools for space walks to repair the International Space Station.

Grafter can remix 3D printing models into new, functional machines, without the need for extensive tweaking or testing.

KUKA, the Chinese-German industrial manufacturing company, creates specialist robotics by using 3D printing technologies. In collaboration with MakerBot 3D printers, KUKA develops robotic arms which are used across a variety of industries.

The Calgary-based company GravityB 3D is using a 60-camera 3D scanning system to create life-like 3D printed figurines of pets and people.

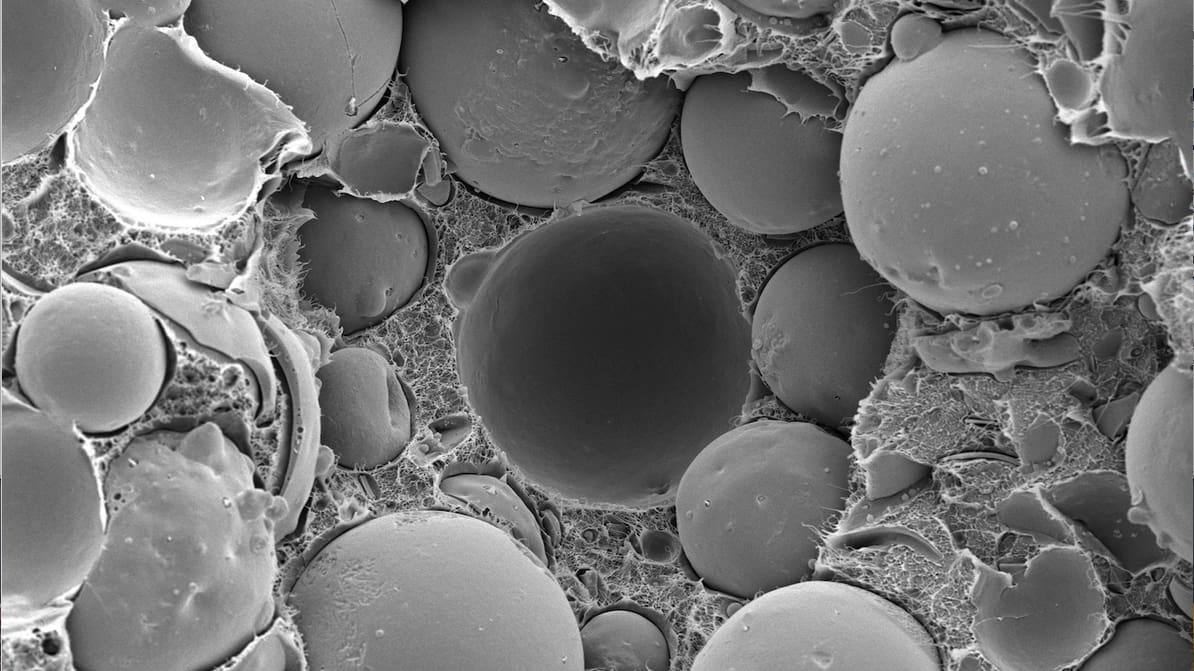

A team of researchers from New York University School of Engineering have developed 3D printable syntactic foam materials. These foams are lightweight composites that offer exceptional buoyancy and strength, and are commonly used for submarine components.

Stratasys is partnering with Dassault Systèmes to supply Unlimited Tomorrow with 3D printing and CAD software dedicated to producing affordable, patient-specific prosthetic devices.

The global community Precious Plastic has created a recycled iPhone case with CNC milling from 3D Hubs. The organization has created an open source production ecosystem that includes a plastic waste shredder, an filament extrusion machine, an injection molder, and a compressor to help process the molds.

Engineers at Rutgers, the state university of New Jersey, and the New Jersey Institute of Technology have developed a 4D printing method which may find application in tissue engineering and targeted drug delivery systems.

In collaboration with GlassesUSA.com and the Polish 3D printer manufacturer Sinterit, Finnish designer Janne Kyttanen has released 3D printable eyewear designs that you can customize and print as a single frame.

A team of Chinese plastic surgeons and tissue engineers have devised a method to 3D print cells which assemble into a replica of a patient’s ear.

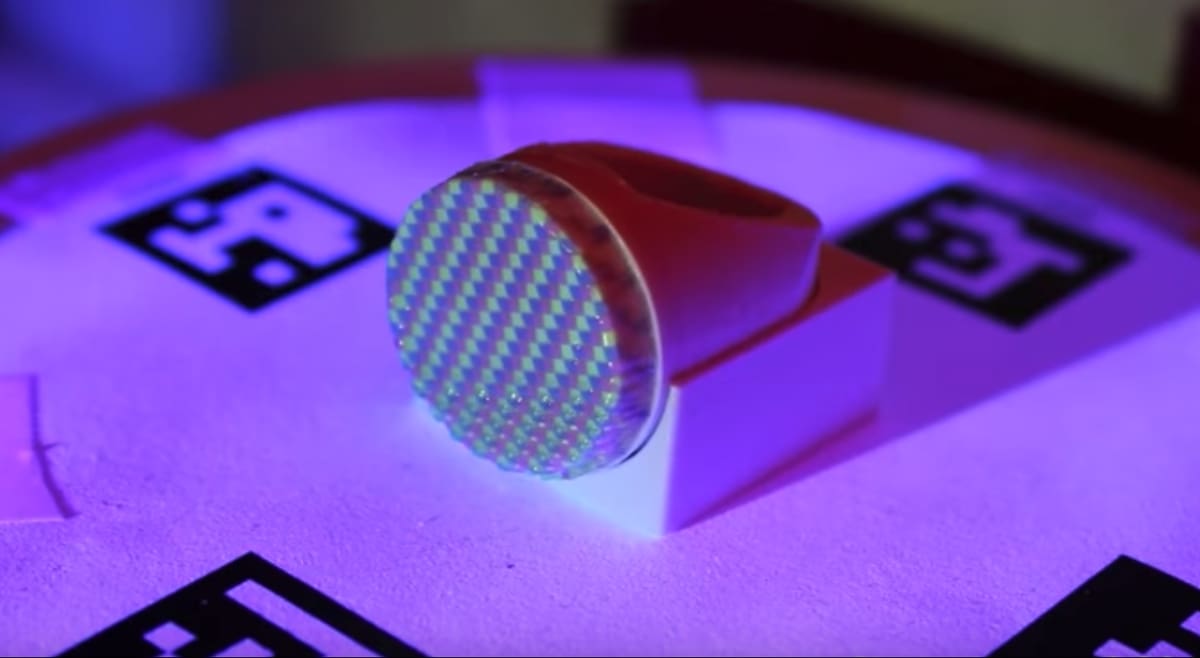

A team of researchers from MIT CSAIL have developed ColorFab, a platform that enables the creation of 3D printed objects that change color after production. This process could be integrated into the fashion and jewelry industry, and would help promote waste reduction.

The Real Play Coalition has released a 3D printed replica of Albert Einstein’s famous Anker Steinbaukasten toy set. These blocks, which can now be 3D printed at home, are designed to foster the imagination and creativity of children.

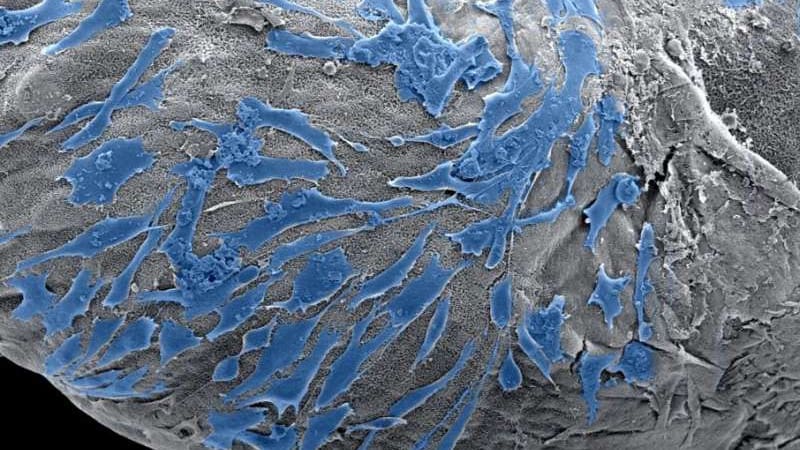

Researchers from the Singapore Institute of Manufacturing Technology are using 3D bioprinting method to control melanin-production in skin cells on a biomimetic tissue substrate, creating human-like skin pigmentation.