Researchers have developed a new tool to produce 3D printed "metamolds", which can be used to fabricate optimized silicone molds in a quick and cost-effective manner.

Researchers appear to have found a simpler method for 3D printing metal by using bulk metallic glasses (BMGs). The process is still theoretical, but the researchers believe it may soon become commercially usable.

OctoPrint, the open-source control software for 3D printers, has issued a reminder to its users to invest time to properly secure internal services and configure settings after a report from the Internet Storm Center (ISC) which shows the dangers of unsecured interfaces.

Carbon has launched MPU 100, the first-ever medical-grade material for its Digital Light Synthesis machines. It offers a combination of mechanical strength, biocompatibility, and sterilizability.

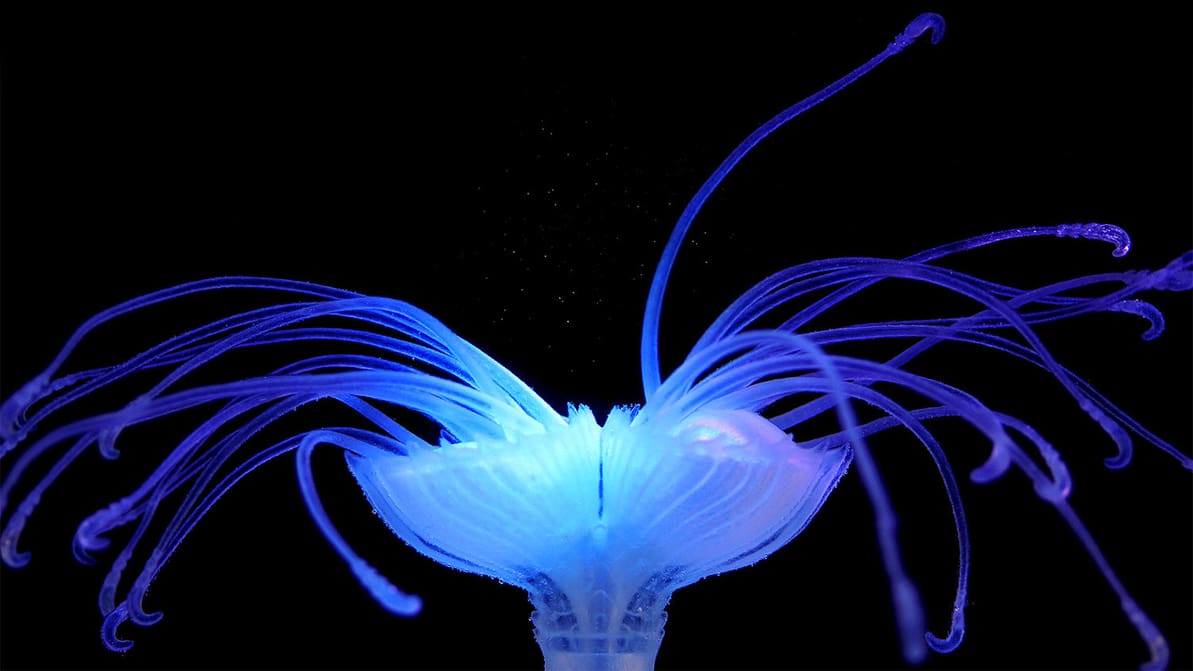

Industrial designer Nicole Hone has created a collection of 'Hydrophytes', which are futuristic, aquatic plants that are made with multi-material 4D printing technology.

Surgeons at the University Hospital Basel in Switzerland are cutting down on operating times for head, neck, face and jaw surgeries by 33% thanks to 3D printed surgical guides.

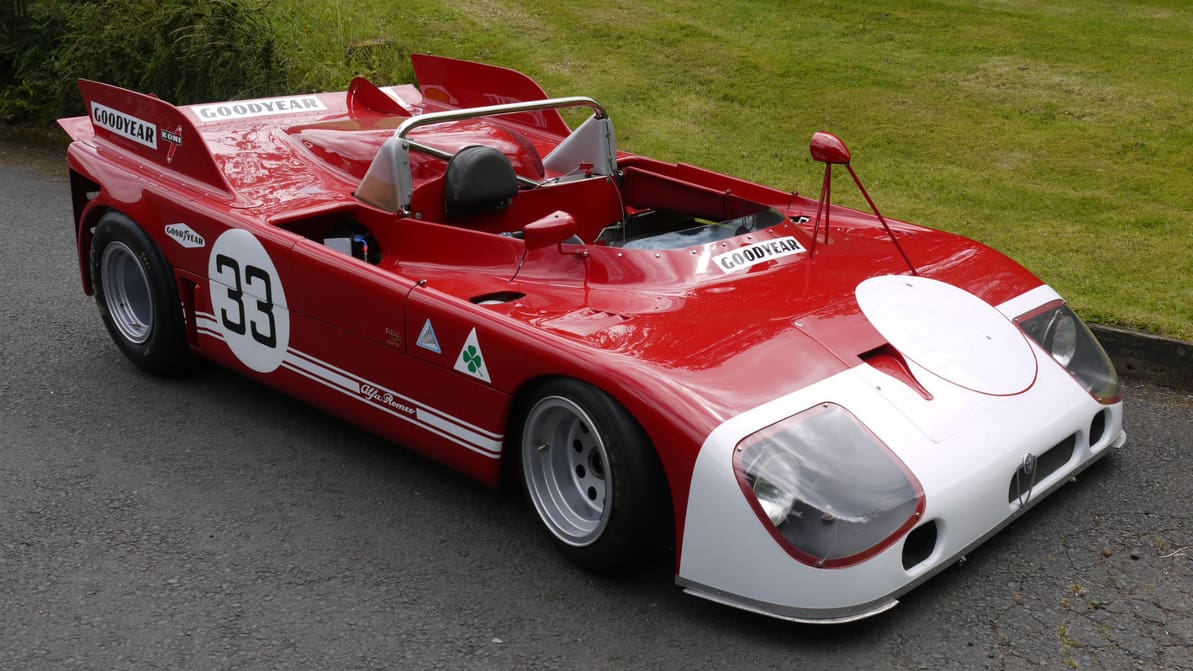

KW Heritage, a restoration service from engineering firm KW Special Projects, used 3D scanning and 3D printing to restore the engine cover of a rare Alfa Romeo Tipo 33/3 racing car, which will be on display at the Goodwood Revival motor racing festival.

A British engineer, programmer, and maker recently took to YouTube to display his upcycling creation. Using 3D printing and electronics, Robin Hartley turned an empty Cadbury's hot chocolate tin into a portable speaker.

A new crowdfunding campaign for an interactive and home-printable 3D Zoetrope has smashed its funding goal. The project, called 4-Mation, uses 3D objects and strobe lights to create impressive, moving visuals. There are four different animations available to back on Kickstarter.

Dazz 3D, a Chinese technology company has launched a Kickstarter campaign for the Dazz 3D LCD 3D printer. Promising high-quality resin 3D printing, a safe air purification system and an automatic refilling system, the campaign has already smashed its funding goal of $30,000 with over $100,000 raised.

Engineers from MIT developed a new technique called the direct-write colloidal assembly process. It can build centimeter-high crystals made from billions of individual colloids. They did this by uniting the principles of 3D printing and self-assembly.

University of Calgary students are working on a project which could provide astronauts with 3D printed plastic tools made from feces and genetically engineered bacteria. The students recently tested the tools out during a flight on the "Vomit Comet".

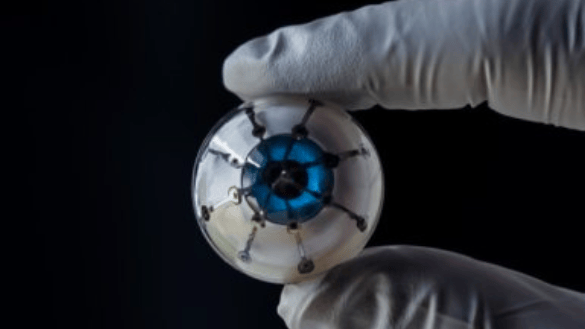

Researchers at the University of Minnesota have 3D printed an image sensing array on a hemisphere: in essence, a bionic eye. It is the first-of-its-kind and, hopefully, will be used to help blind people see.

Material scientists from the US Army Research Laboratory are using an atom probe to explore the structure of metal and ceramic specimens at the atomic-level and creating 3D models of the results.

When a German designer, Studio 7.5 collaborated with a French 3D printing company, XtreeE, the result was an interesting 3D printed bench with a woven pattern.

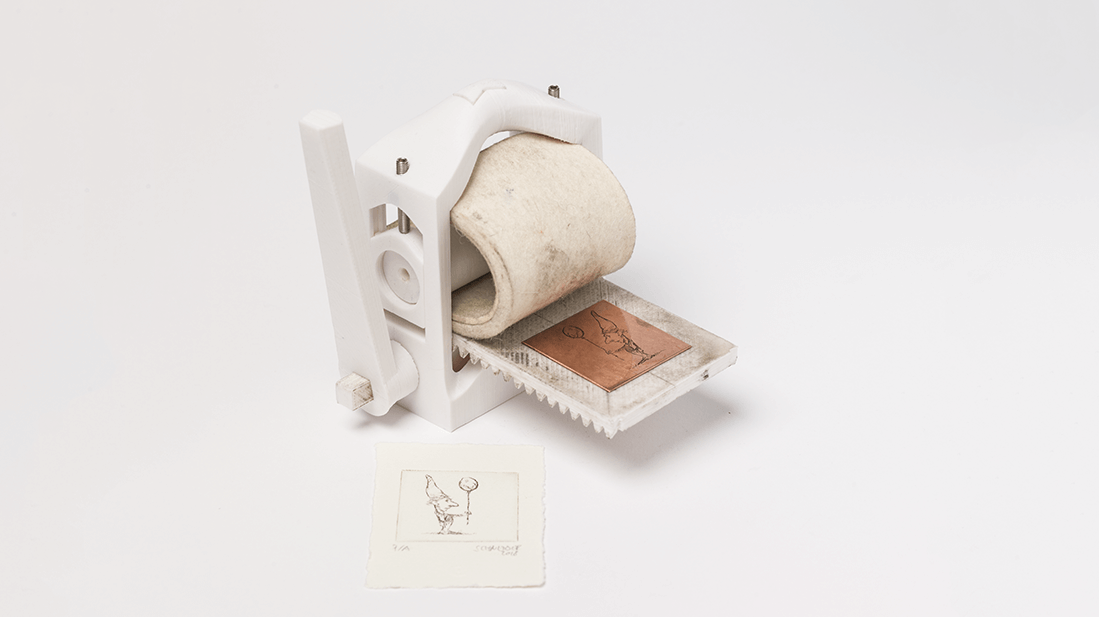

The Open Press Project is the world's first 3D printed printmaking press which is a lot less expensive than traditional presses and just €5 in materials.

3D printing could reduce the wait time for vital parts that soldiers in the US Army face while on the battlefield or in remote locations. Researchers have found a way to use recycled materials from the base to create strong and usable filament.

A Waikato University masters student is using 3D bioprinting to grow life-size tumor cells in 3D which may help improve treatments. Eventually, it may be possible to take cells from a patient, grow a tumor and see which treatments work best on it in a laboratory.

A team of US Marines in Maryland were tasked with finding a landing gear component that attached to the door of a F-35 stealth fighter aircraft. By using 3D modeling and printing, they were able to replicate the component for just 9 cents.

Researchers at NYU Tandon and NYU Abu Dhabi have developed the means to insulate 3D printing from piracy by converting flat QR codes into hidden features within a printed part.