The evolution of 3D printing should not be a matter of additive manufacturing companies competing with each other. It should be about them collaborating in order to compete with traditional manufacturing. Autodesk, the leading publisher of 3D software, wants to be the spark that will set off a new phase in 3D printing. Autodesk’s Spark will be a complete ecosystem, where 3D software, 3D imaging and 3D printing companies work together, leveraging on each other’s strengths to reach millions of people.

A maker’s dream

Autodesk will help the process by investing up to $100 million in Spark, following the vision of its CEO Carl Bass. The company has already introduced a number of free, easy to use smartphone/tablet apps, web apps, and programs within its constantly evolving 123D App suite of software. Last month, Autodesk launched Ember, the first professional, SLA/DLP-based, open source 3D printing platform. What is more, the company established partnerships with some of the most interesting start-ups and companies involved with 3D printing.

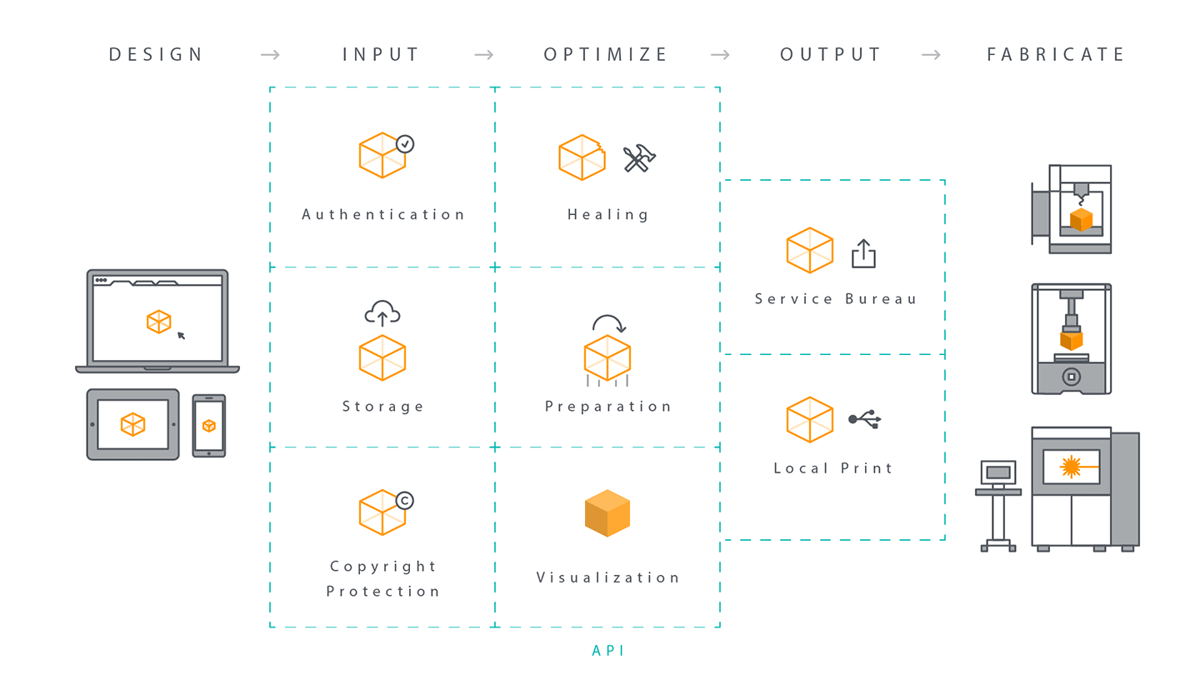

Spark is a set of open source APIs and free cloud services that enable 3D applications and services to better prepare, optimize and deliver 3D models for any 3D printer or service bureau. It is based on the conception that, while additive manufacturing offers unprecedented opportunities, it is still complex, expensive and not always reliable. Until now, proprietary technologies and fragmented processes have limited innovation in and adoption of 3D printing.

3D printing united

To address these challenges, Autodesk developed a professional open software platform that will offer a set of industry standards for all aspects of the 3D printing ecosystem: software, hardware, materials and services. “Gone are the days when the approach to innovation in the manufacturing segment was closed-end and top-down. Many market segments including the value resulting from close collaboration with entrepreneurs and start-ups that can bring the best ideas and 3D printing is no exception,” said Samir Hanna, general manager and vice president of Autodesk. “Spark Investment Fund will be a means by which the true innovators will improve 3D printing, helping the world benefit from the fantastic opportunities offered by this technology.”

The companies that will contribute to turning this vision into reality share Autodesk’s newly found consumer-oriented approach and passion for blending digital and physical 3D. Autodesk even managed to integrate HP and HP’s “Sprout blended reality ecosystem” that is based on the MultiJet Fusion (MJF) technology for 3D printing. Also included are 3D printer manufacturers such as Ultimaker and Dremel and Big Rep, which produces a large-size 3D printer for creating full-size products. ExOne, a leading manufacturer of large-size binder jetting metal 3D printers, is also on board and it is a perfect match as the German-American company has always focused on educational applications for its machines.

Tomorrow’s distributed factories

There also are several companies that developed tools for making 3D printing more feasible and accessible. These include Authentise, which developed a system for streaming files directly to 3D printers in order to make IP and file management safer and more efficient. 3Dindustri.es is another company working on organizing the 3D printing ecosystem through online software systems and database management tools. 3D Hubs is also “organizing” 3D printers and building a global distributed manufacturing network

Autodesk Spark members also include a number of highly visionary studios such as Ronald Rael’s and Virginia San Fratello’s Emerging Objects. They have conducted some of the most advanced research on materials for binder jetting 3D printing technology. MIT’s Nervous System and Francis Bitonti are among the top designers working with parametric software and 3D printing applications in wearables. And then there is Local Motors, a company which has been using large-scale 3D printing and shared, open source creative solutions to radically change the automotive industry.

This revolution is happening at all levels. Tesla Motors and Space X founder Elon Musk paved the way when he released all Tesla patents to demonstrate that the electric car industry should not compete within itself but should work together to challenge traditional motor companies. Carl Bass is betting $100 million on the idea that the same is possible in manufacturing. If Autodesk and its collaborators are successful we are all going to win.

License: The text of "Autodesk is betting $100 million to spark up the future of manufacturing" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.