Why you should read this: because Autodesk’s Ember 3D Printer has the potential to radically change the 3D printing and the entire manufacturing industry.

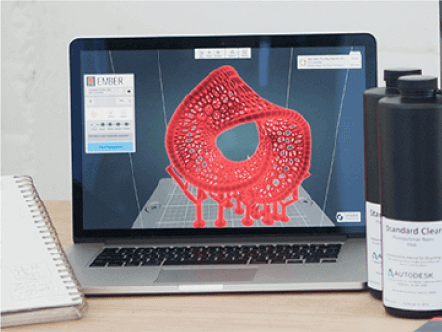

Revolution is coming full circle. Making a 360° degree rotation. That is what Autodesk is doing with the Ember 3D printer platform. Ember 3D has seen the company go from being a professional – strictly licence based – software company to an open company making software, hardware and even materials. That is the Ember promise, and it is a big one, since the $5,995 DLP 3D printer, which hit the market last January, is growing by the day and the progress is visible. Online, offline and in the physical world.

After Autodesk developed a set of open software tools dedicated to modern 3D printing applications, included in the 123D App suite (All3DP’s review here), it was only a matter of time before they would announce a user-friendly 3D printer that could reliably produce high-quality results. Nothing less than that could be expected from Autodesk, even if we are talking about their first ever approach to 3D printing hardware, or to hardware in general for that matter. So, Ember was announced in 2014 and officially released in early January 2015.

Lowering the Entry Point to Professional 3D Printing

The price classifies it as a high-end desktop model, so expectations are high. Our impression: The Ember can deliver. Starting with resolution: in a relatively small 64 x 40 x 134 mm build volume, Ember can achieve 50 microns on the X and Y axes and down to 10 microns on the Z axis (which is real and quite impressive). What makes it different is that it uses a rotatable head that crystallizes a special (open source) resin allowing for higher printing speeds without sacrificing quality (see all specs here).

The testing gives 15 mm per hour at 25 microns with the complexity of the model not affecting it whatsoever. Speaking of item numbers, Ember can receive an installation of additional building plates (at the price of 100$ each) to allow the simultaneous building of multiple objects. The limit is two, though, and the building procedure sees one platform print begin as the other one finishes. The maximum build volume is which equals out to 0.343 liters, is limited by its digital projection technology, although it is still enough for a wide range of applications from prototyping to wearables. Finally, the kinematic coupling in the build-head ensures a secure fit, thus reducing the calibration times.

Open Everything

Along with the resin materials, Autodesk aims at an open source (hardware and software) 3D printer and so is gradually releasing the technical specification details of each of the components, materials composition and drawings. It supports several third party resins, including some of those from its main competitors in this segment: DWS, Formlabs and Asiga, along with pure-play material manufacturers’ such as MadeSolid.

Knowing the benefits of creating communities that will embrace your products and contribute to them, Autodesk promises to soon release Ember’s CAD designs and new material formulations under public licenses. This it will make them available to everyone. That guarantees 3rd party materials will also work properly with the printer. That’s a radical departure from the strategy implemented by several other 3D printer manufacturers.

The importance of this became evident as early customer feedback indicated some issues with the resin trays (which cost $50 each) cracking when certain 3rd party resins are used. Although Autodesk isn’t refunding the trays, nor providing replacements, the company is offering the resin tray 3D model for their customers to print it out of ABS plastic.

From Physical to Virtual (Again)

Along with all the API’s of the Spark software ecosystem it is based on, Ember also implements a highly innovative 3D printing software interface that is entirely web-based. The EmberPrinter platform lets you remotely control several different 3D printers in remote locations, easily keeping track of all your prints and queued jobs. STL files can be loaded directly from Thingiverse, from the 123DApp network or from the local hard drive. The online platform means the community is active around it, and users can quickly access information and contact their peers to solve issues and facilitate the development and adoption of the platform.

All3DP’s verdict

My conclusion is that the printer is on the expensive side for a purely consumer audience. But it’s certainly a revolution in the making, one that already is pushing the limits of 3D printing through a valid open source approach that goes hand in hand with Autodesk’s strategy of giving educational institutions free access to its entire professional software library. The potentially huge 3D printing business of the future will be based on the learning experiences of today, and Ember – after the revolution – is already in the frontlines for the future of making things.

License: The text of "Autodesk Ember 3D Printer: First impression" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.