Bookbinding is an intricate and complex process that involves having a high level of skill and requires a lot of time. But one Dutch craftsman is set to change this through his use of 3D printing.

Luc Volders is a bookbinding hobbyist. While he still does all the work by hand, he has found a way to use 3D printing to simplify greatly the difficult process of creating embossed covers.

He explains on his blog: ”One of the most difficult things to do as a hobby bookbinder is to make a cover with relief - also called embossed. I made some of them and it was a tedious job which I never really got right”. To do this, Luc uses his

How to use 3D Printing for your Book Binding

If you have your 3D printer, then the process does not need to be a difficult one, as Luc explains in the detailed instructions on his blog.

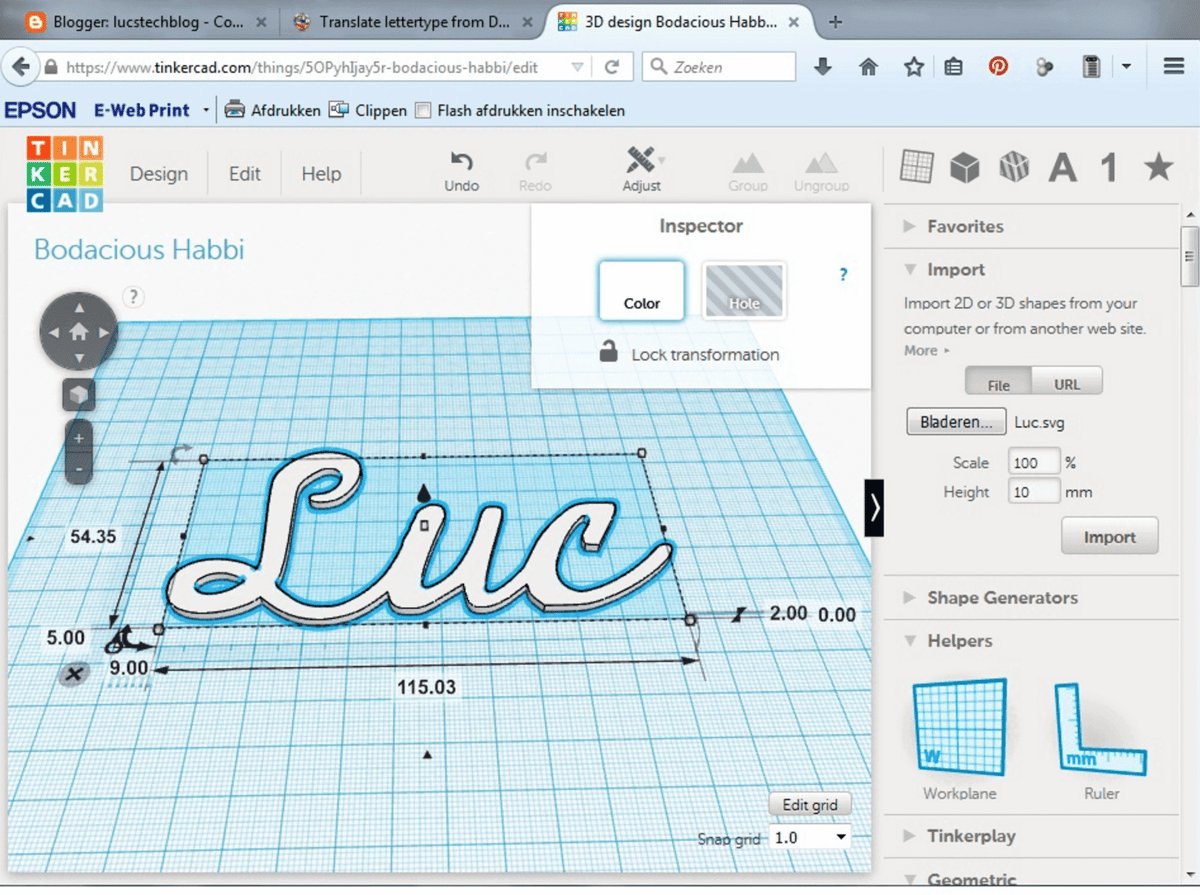

Simplified, the process works like this: the first step is to find a typeface and a picture you want to use for the job and save everything as a JPG file. Luc suggests using Tinkercad to scale the subject and make sure your height is 2mm.

For the 3D printing part, it’s as simple as that – you just need to download your STL file and use your favorite 3D printing program to slice and print it.

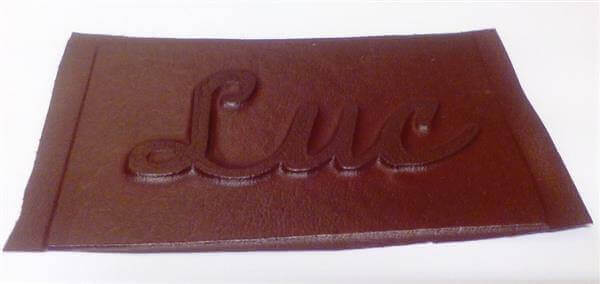

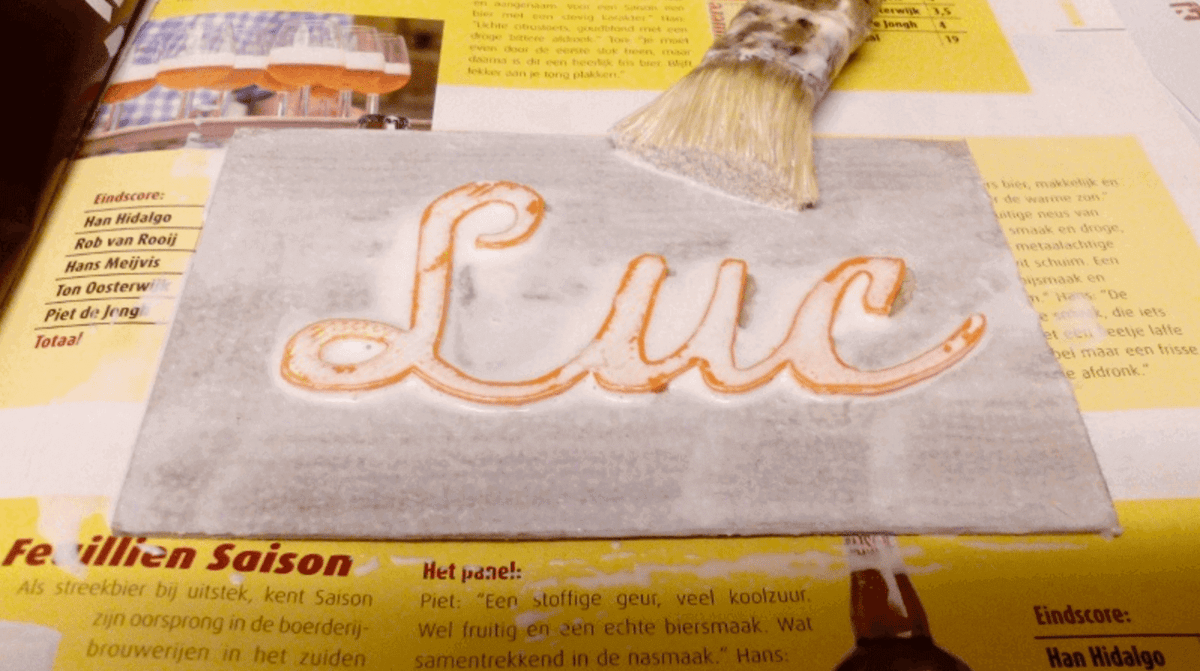

The next step requires more skill as your 3D printed result should then be glued to a cardboard surface and left to set for twenty-four hours before the work on your book cover can begin.

Luc uses his own professional pressing plate to emboss the cover. He adds: “Now put this ‘hamburger’ in your press and press it really tight. As tight as possible. This means of course that you will not be able to use this technique without a press.”

What do you think of this design? Will you be using this 3D printed technique to update an old-fashioned tradition?

License: The text of "Better Book Binding Thanks To 3D Printing" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.