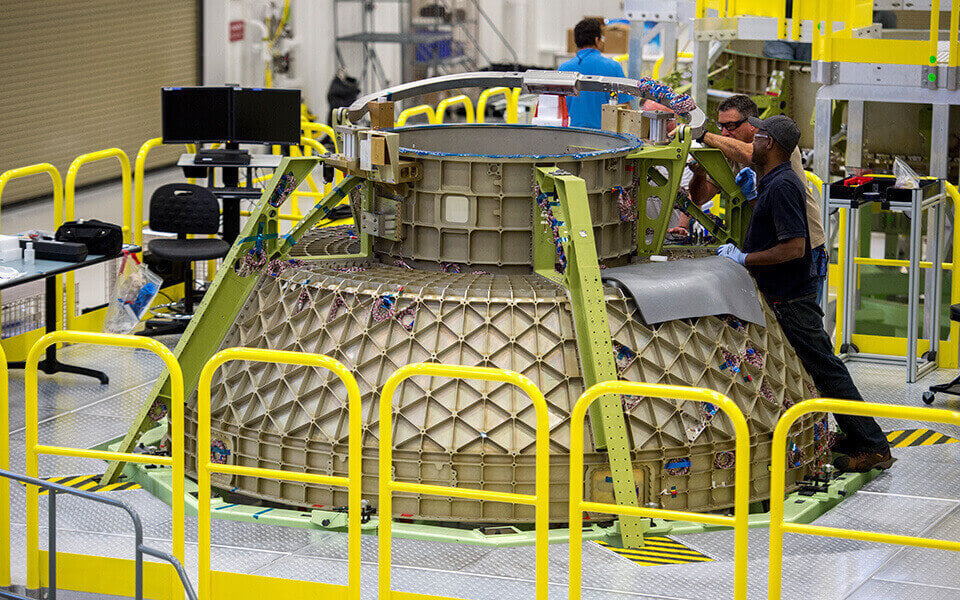

Boeing’s CST-100 Starliner space crew capsules will use more than 600 3D-printed parts. Some of them are even made of plastic.

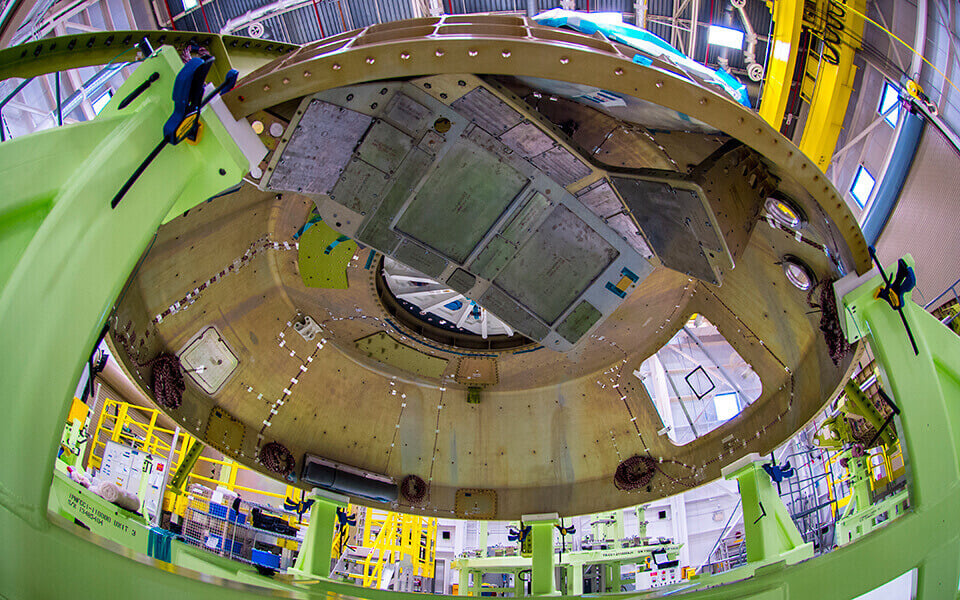

The CST-100 Starliner is Boeing‘s flagship space program. With a reusable crew capsule, designed for NASA’s Commercial Crew Development program, is an attempt to broaden space travel beyond the confines of government-led missions.

Boeing plans to use more than 600 3D printed parts on the new crafts. Therefore, they have hired the small US company, Oxford Performance Materials, to fabricate 3D printed parts for its new Starliner space taxis.

A Boeing representative told Cnet the company relies heavily on 3D printing since 2003. So far, 50,000 parts were made with additive manufacturing. She added that Oxford’s 3D-printed parts would be used the “air revitalization system, interior closeouts and support structures” of the Starliner.

Save Weight, Reduce Cost With 3D Printing

Not every 3D printed part in the cabin will be made with metal 3D printing on an EOS printer. Oxford also wants to use materials like Polyetherketoneketone (PEKK) for some parts. This strong plastic material has to be printed at high temperatures. But it offers high strength and offers resistance against heat, radiation and a variety of chemicals. Also, it’s relatively easy to process.

Larry Varholak, president of Oxford’s aerospace business, said in an interview: “What makes it valuable to NASA and Boeing is this material is as strong as aluminum at significantly less weight,” he said.

So far, Boeing said the weight savings on Oxford’s parts is about 60 percent compared to traditional manufacturing. In the aerospace industry, that’s good news: Every pound counts if you have to shoot it into space.

The Starliner is designed to transport up to seven passengers or cargo to a low-Earth orbit – like to the International Space Station. Test flights are scheduled for June 2018. The first crew will launch into space in August 2018.

License: The text of "Boeing’s Space Taxi Will Use More than 600 3D Printed Parts" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.