Researchers from Buffalo University, USA, are using a modified 3D printer, ice and liquid nitrogen to create record-breaking low-density graphene structures. They hope the method could be a commercially practical path to mass produce the wonder material.

Graphene is the subject of much research all over the world, with efforts both in the material’s uses and efforts to create large usable quantities making headlines. Basically, the material is a two-dimensional latticework of carbon atoms.

It finds itself at the center of many industries’ focus for its electrical and heat conductivity, and remarkable mechanical strength. However, despite graphene’s seemingly unreal roster of properties, researchers face many problems shaping it into useful three-dimensional structures.

But this is changing. All3DP recently reported that a team from Rice University and Tianjin University made useful quantities of graphene at room temperature with simple base materials — namely sugar. It seems that with every great leap towards creating commercially viable graphene, 3D printing is right there as the tech that makes it possible.

This time around however, in addition to international plaudits, the researchers at the University at Buffalo have also received the Guinness World Record for creating the “least dense 3D printed structure”. In fact, the researchers are currently able to produce a graphene density of 0.5 milligrams per centimeter.

Chi Zhou, Assistant Professor of Industrial and Systems Engineering at the university and chief researcher of this project explains:

“The major difficulty of printing graphene is caused by the complex graphene morphology and nontrivial material forming mechanism… It is very challenging, if not impossible, to assemble the 2D graphene sheets by heat fusing, photocuring, chemical bonding as is typically used in traditional 3D printing technologies.”

3D Printing Graphene with a New Technique

The team’s method allows for 3D printing macroscale graphene structures, without sacrificing the material’s useful properties. To do this, they use a process known as freeze-casting.

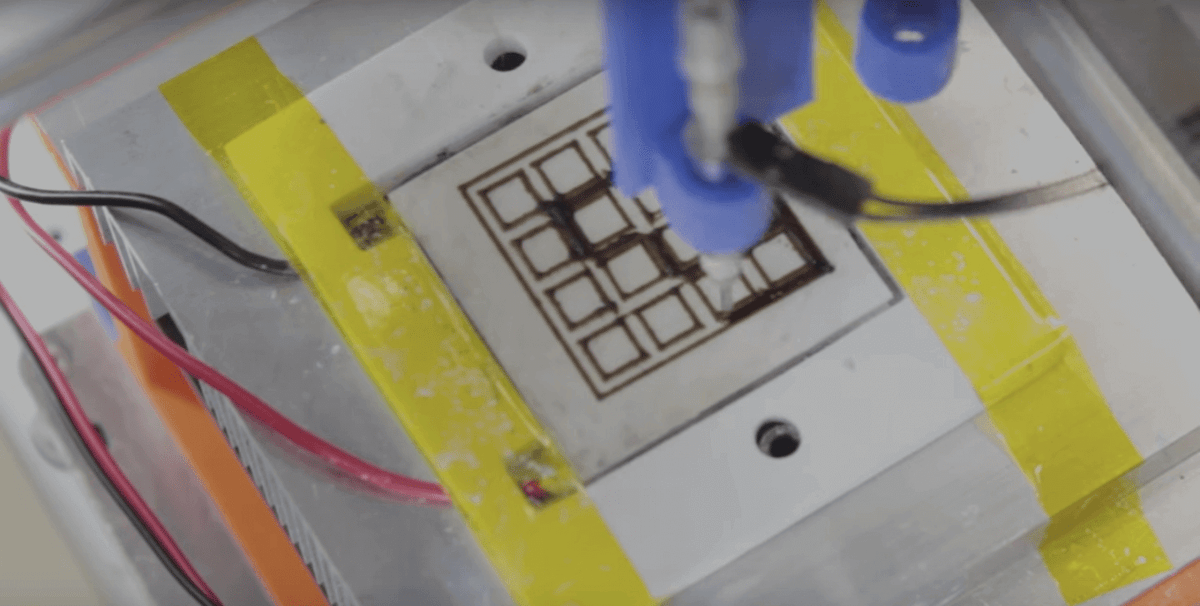

Their modified, open-source fused filament fabrication 3D printer – an Ultimaker 2 Go — now uses an inkjet printhead. Through this the researchers deposit a graphene oxide and water mixture on a cold plate at -20°C, in a freezer.

Because of the low temperatures, the graphene can build up layer by layer without losing its intended shape. Ice crystals form in the solution as it freezes, which pressures the graphene sheets within to spread out into a complex 3D layer.

After the print is complete, the researchers freeze dry it in the liquid nitrogen. By doing this, the ice evaporates and a graphene aerogel remains. Zhou also adds:

“The end result is graphene aerogel, a porous and superlight material in which the liquid part of the gel is replaced by air, allowing it to retain its shape at room temperature… The process has proven to be very effective and successful.”

Zhou explains that thanks to this technology, the team can change the scale of the 3D printed structure. By doing this, they can create either small or big prints.

What this means is that researchers could begin using the material for a range of applications. Examples include; flexible electrodes and all-solid-state batteries but also electrochemical catalyst templates.

Source: ENGINEERING.com

License: The text of "Researchers 3D Print Impossibly Light Graphene In a Freezer" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.