Why you should read this article: It gives you profound insights in the 3D printing world.

Amazon’s decision, last July, to make its interest for 3D printing public has captured the attention of the Hi-Tech world, which had already been somewhat intrigued by the many announcements at the Consumer Electronics Show in Las Vegas, in January 2014. A year ago, 3D printing was still something of a mystery, a temporary phenomenon that enthralled more from a theoretical than a practical point of view: the ability to create real objects, from 3D virtual models, opened breathtaking scenarios but clashed with the actual limits, technical and operational, of the available hardware.

Today, less than a year later, everything has changed. Consumer 3D printing, an evolution of those rapid prototyping and additive manufacturing technologies that, at industrial level, have existed for almost 30 years (and yes: allow the creation of real objects, plastic or metal, from a digital model), is evolving a dizzying pace: personal 3D printers cost less and, at the same time, are the more advanced and easy to use. 3D printing services online and offline are spreading like wildfire, relying on the consumers’ desire for unique products, customizable and impossible to achieve through traditional manufacturing techniques.

A 3D printer for every home?

Consumer 3D printing will not disappear but rather is about to enter people’s houses, giving the possibility to create “on demand” objects of any kind, or customize them online and have them tailored-made by industrial 3D printers, capable of creating full color objects (in millions of colors) of any kind and “physical photos”, obtained from 3D scanning systems. From smartphone cases to miniature “mini-me” statuettes, the list goes on and on. Although most applications so far only for plastic (for home 3D printers) and metal (for industrial systems) objects, the research on materials moves fast: it is already possible to 3D print with wood and ceramics; soon it will be possible to do it with food and one day even with human cells to create artificial organs. The process has but begun.

Supporting the growth of 3D printing is no longer just the enthusiasm, now there are also the numbers. Until recently, the major research institutions that follow this field (Wohlers Associates and Gartner) focused on the explosive growth of industrial systems. A new research conducted by Smartech Markets Publishing found that in 2013 over 46,800 consumer 3D printers were sold (ie those that cost of less than 5,000 dollars), a 32% increase. To further support these data, the two most important 3D printers manufacturers in the world, Stratasys and 3D Systems, have respectively doubled and tripled their sales in the consumer segment.

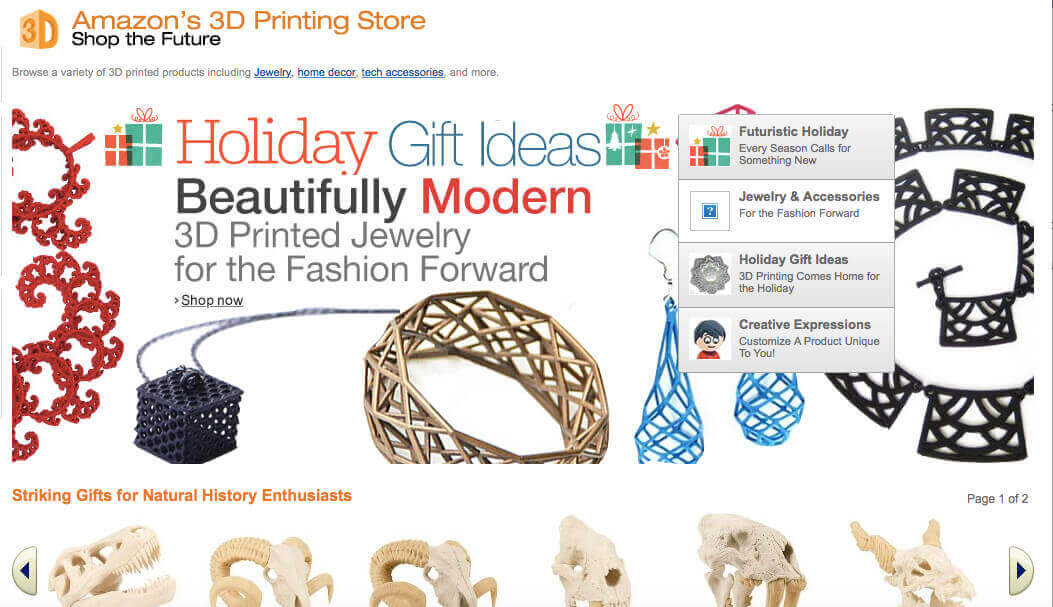

To paint a more complete picture, Wohlers Associates (which we interviewed at All3DP) determined that the entire additive manufacturing industry (as the 3D printing industry is generally defined) is now worth about $3 billion, after 35% a growth of in 2013). If additive manufacturing grew to be worth only 2% of the whole manufacturing world (and experts are convinced it will happen by 2030), the resulting global turnover would amount to $200 billion (a 6600% increase). That’s why this market is tempting to many. Amazon included.

Evolution and Distribution

The 3D printing evolution runs parallel to that of many important consumer electronics products of the past. Just like 2D printers, (from which it took its name) it is offering the possibility to take computer content out of the virtual world: it used to be only photos and texts, now it’s real objects. At the same time it also follows the personal computer’s evolution, with production speed accelerating at Moore’s law rates (doubling in a relatively short period of time) and the ability to manage increasingly “problems”. A 3D printer is also an appliance: GE claims that by 2015 there will be a 3D printer in every home and that we will regularly use them to create domestic items and even food.

In many ways 3D printing is also an entertainment platform. The maker movement, of people using personal manufacturing tools, and especially 3D printer for their high versatility, is based on collaborative challenges similar to those experienced in gaming platforms (only it’s real), and the 3D software that is inextricably linked with 3D printing devices, is at the base of those same video games. With which it enjoys a love hate relationship, in the sense that the videogame companies see 3D printers both as a great potential partner and a dangerous competitor to that most precious commodity which is people’s time.

3D printing runs parallel to entertainment content on the tracks of IP protection as well. Switching from analog to digital distribution of multimedia content was a very difficult transition. That switch from analog to digital distribution of physical goods could be exponentially more complex, although this scenario is still some years away (at the consumer level).

Alternative to home printing: 3D print shops

Until then 3D printers will remain exclusive products for those who already know what to do with them: designers, architects, engineers, artists, technology enthusiasts, 3D graphic artists and modelers, movie makers, educators and just about every kid who will get his or her hands on one. Which makes already a significant critical mass for large companies such as 3D Systems and Makerbot to tailor their Cube and Replicator lines respectively to the needs of these who just want to 3D print. Staples, the largest office chain in the world, was among the first to sell the Cube and regularly offers 3D printing services through mcor Technologies’ full color 3D printers. It has since been joined by Home Depot, the biggest US home improvement retailer, which is selling MakerBot’s systems. That’s because a 3D printer is also, actually it is first, an incredibly versatile tool making tool.

The phenomenon is spreading rapidly: there are now 3D print shops in all major cities of the world and also in many isolated small towns. That is because, along with the total customization and disruption of the economy of scale (the cost for a single 3D printed object is the same regardless of the number of copies produced) the greatest promise of 3D printing is the delocalization of manufacturing, that is, the possibility of producing any thing everywhere: all that’s necessary is an Internet connection and importing the raw material.

Future on Demand

Despite the justified enthusiasm for the possibilities opened by consumer 3D printing, it is still a niche market and will be for some years. The limits of the objects that you can print (single material, with flawed and uneven surfaces) remain significant. Paradoxically, at a consumer level, one of the main limits of 3D printing (which is also known as rapid manufacturing) is the time required. Creating an object from scratch with traditional manufacturing methods can take months, if not years, while for a 3D printer it is a matter of days, if not hours and minutes. Yet to 3D print a household item or a set of Lego definitely takes much longer than going to a store close to home to buy it. It does offer some advantages with respect to eCommerce since it would be possible to eliminate time and shipping costs and just let the customer download a file.

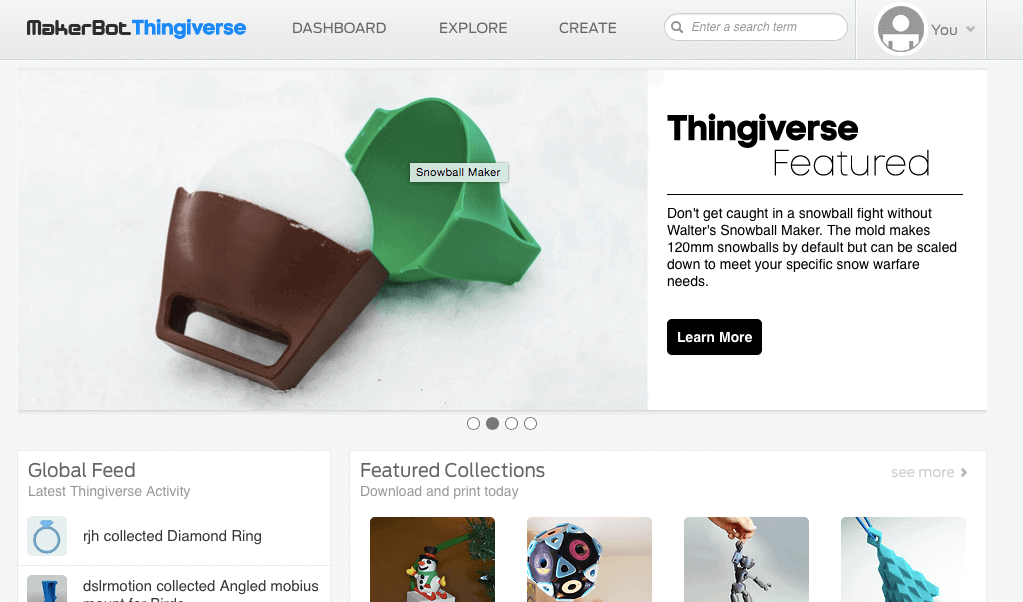

Digital files with instructions to reproduce the object, are generally in STL format, which is somewhat like “the MP3 of objects”, and can be downloaded free of charge from a variety of online databases. The largest printable objects container is MakerBot’s Thingiverse, the universe of things: it now contains over 400,000 items including accessories, gadgets, toys and even shoes and jewelry. Since last September it has grown by 100.000, and by over 300.000 since the beginning of the year. You just buy a MakerBot Replicator, pull it out of the box, turn it on and connect to the WiFi network at home. Connect to Thingiverse, using the computer or smartphone App, and then just press the “Print” button to print almost anything in it. The feeling you get from having an entire universe of objects at your fingertips is a powerful one and the best guarantee for the future of 3D printing.

Additional reading

If you want to read more about the industrial uses and chances for small businesses, please read the All3DP-Interview with industry consultant, analyst, author, and speaker Terry Wohlers “We expect thousands of new companies to offer 3D printed products”.

License: The text of "What you can expect from 3D printing" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.