Carbon is introducing its production-scale 3D printing materials program, offering larger resin volumes and a new pricing structure.

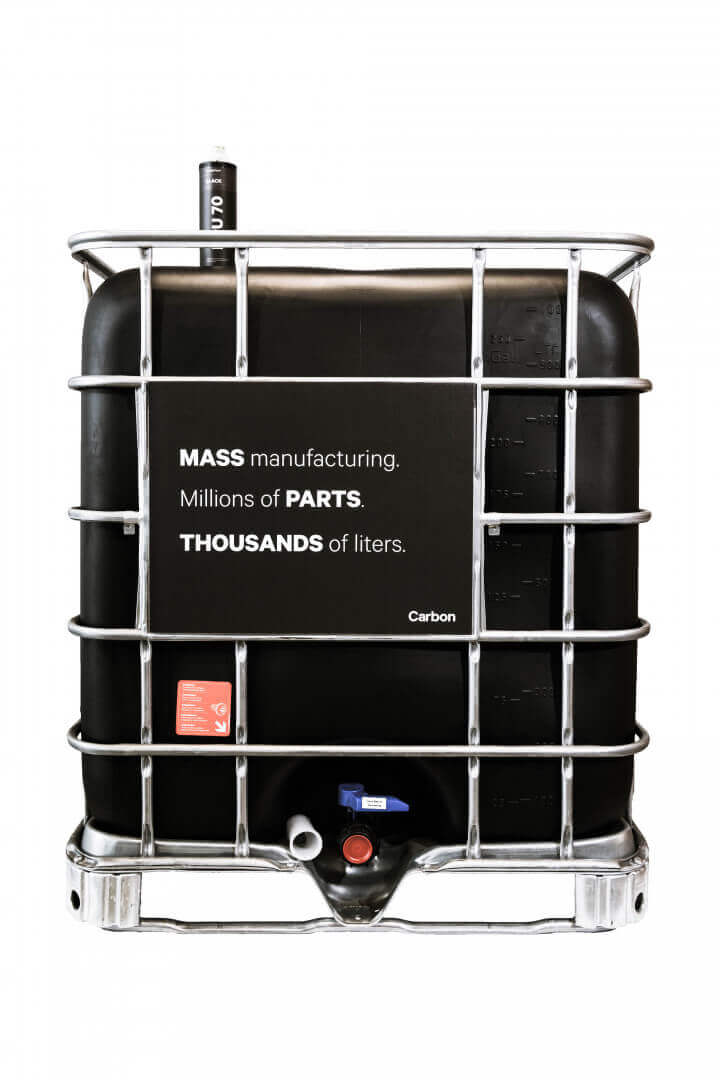

The Silicon Valley 3D printing startup Carbon is launching its new materials program to help cut production costs for high-volume manufacturers. Now, customers will be able to purchase the company’s 3D printing resin material in bulk packaging, reducing the price by around 40 percent.

Carbon took the 3D printing industry by storm a couple of years back, unveiling the incredibly fast Continuous Liquid Interface Production (CLIP) technology. Since then, the startup has enabled full-scale production for Adidas Futurecraft 4D footwear, released two 3D printing systems, as well as the expansive SpeedCell system.

With the new materials program, Carbon will be able to service its customers in a more practical and affordable way. The first material that will be released in bulk is the RPU (rigid polyurethane) 70. The price per liter is being reduced $250 to $150. By collaborating with its network of global partners, the company plans to bring that price down to less than $100/liter over the next year.

“This production volume materials approach will allow us to ensure that our partners like adidas, which will be printing thousands or millions of parts, can do so economically compared to other manufacturing methods such as injection molding. No other 3D printing company has offered this because they do not have the combination of a complete system for 3D manufacturing combined with first class materials that enable additive manufacturing at scale. Carbon now does offer that complete package,” says Carbon CEO and Co-founder Dr. Joseph M. DeSimone.

Larger Resin Volumes Equals Larger Production Capabilities

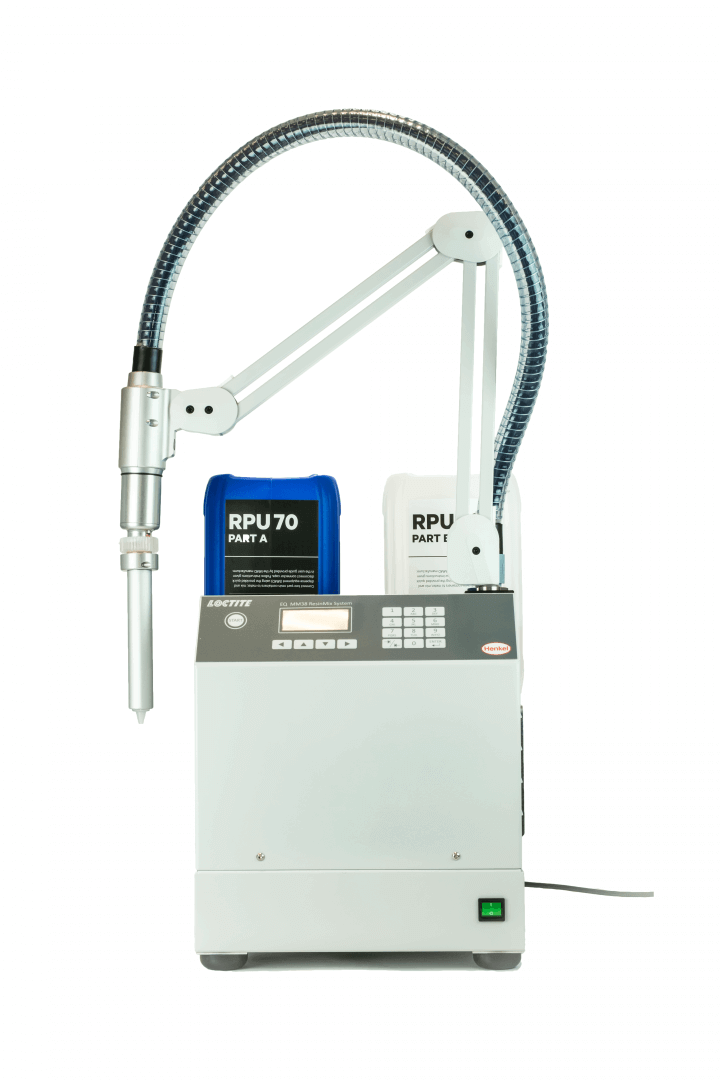

Alongside the materials program will also be a new dispensing instrument called the MMD (meter mix and dispense). This tool was developed through a partnership with global adhesive solutions pioneer Henkel Adhesive Technologies. The accessory will complement the SpeedCell system, and has already been implemented by at least one partnering company.

Some of Carbon’s big name clients, such as Ford and Adidas, are already preparing to implement the new production enhancements. For instance, the bulk material discount will certainly benefit Adidas, which is using CLIP technology to mass produce midsoles for the Futurecraft 4D.

Additionally, the 3D printing startup is also expanding its global reach into Europe. Carbon is teaming up with a number of production partners, including Citim, Oechsler, Fast Radius, and Paragon.

Carbon will be at the upcoming TCT Show (as will All3DP), and we’ll be talking to them more about future developments and the materials program. So be sure to stay tuned to our coverage of the conference throughout the week!

Source: Carbon (Press Release)

License: The text of "Carbon Offers Larger Resin Volumes Through 3D Printing Materials Program" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.