Many companies are talking about the Internet of Things. Casa Jasmina, the brainchild of artists, activists and Arduino, makes the fully connected open home become a reality.

Those who are passionate about the new personal and digital manufacturing technologies (additive ones like 3D printing as well as subtractive ones like laser cutting and milling), know there are some places around the world where large companies or institutions and makers come together to explore the possibilities that the future holds.

Casa Jasmina in Turin is definitely one of these.

In San Francisco, there is Autodesk’s Pier 9. In Barcelona there is the FabLab Barcelona working with the IAAC (Institute of Advanced Architecture). In New York, there is the New Lab, which brings together many different companies and studios.

In Turin, Italy, the largest city near the birthplace of Arduino (Ivrea), the open source PCB manufacturer collaborated with the Fablab Turin to create Casa Jasmina, a place where makers and designers can experiment with digital manufacturing technologies. They do so by focusing on the use the IoT (Internet of Things) in a house environment, exploring the domotic applications of the near future.

Casa Jasmina: An Arduino-Powered Home

This Casa Jasmina project is the brainchild of Officine Arduino’s co-founder Massimo Banzi, political activist Jasmina Tešanović, author Bruce Sterling, together with project manager Lorenzo Romagnoli.

Community manager, Alessandro Squatrito, is also ever-present near and inside the house. He is in charge of organizing all the projects and workshops that take place on the premises. He certainly has his hands full. With a background in product design he also spends time creating innovative products for the home, like the popular 3D printed table connector he designed in 2014 and received quite a bit of visibility.

We caught up with him Alessandro to find out a little more about what is going on in the house, especially on 3D printing applications. “Since we opened in June 2015. Leveraging on our partnership with Officine Arduino, FabLab Torino and Toolbox, a local coworking space, we have begun partnering with other companies interested in home IoT applications,” Alessandro says. “For example Valcucine – on of the world’s leading manufacturer of high-end kitchens – supplied one for us to work on and in. In fact, we are soon going to have a student from the Turin Technical University come and work on an IoT project involving this kitchen.”

Casa Jasmina: Three Ways to the Smart Home

In general, Alessandro explained, Casa Jasmina works on three different approaches. One is workshops such as the upcoming Coming Soon project by School of Ma (which stands for “of Machines, Making and Make Believe). Starting next February, they will be using the Casa Jasmina premises for an entire month, working in IoT and design fiction projects.

The second approach is the artist and designer residencies. They use the Casa Jasmina premises to carry out projects which are then published on the Casa Jasmina website. These include several experiments involving the use of digital manufacturing both for technology, science and the arts. One recent projects involving 3D printing is the Filament Sculpture by Lia, where the artist created her own software to study 3D pinpoint hardware as a medium to create a new form of native sculpting.

At Home and Out-of-the-Box

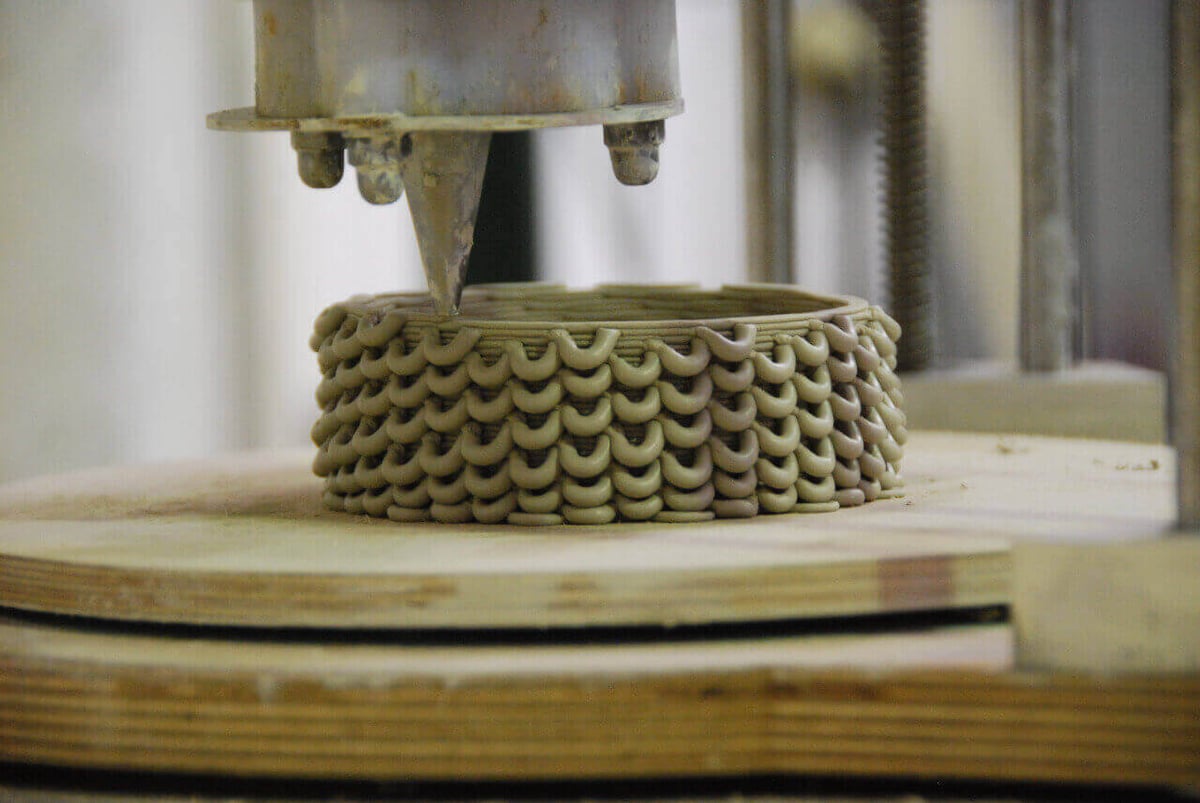

The last aspect is partnering with companies for R&D activities, and 3D printing is involved here once again. Working with FCA (Fiat Chrysler Auto), which is also based in Turin, and the FabLab Turin, Casa Jasmina has access to a robotic arm by Comao (which is an FCA subsidiary). This arm, which moves on seven axes instead of 3 like a 3D printer, can be used to extrude any kind of material. The team focused on ceramic pneumatic extrusion in the InFORMed Clay Matter project. Alessandro explained that at this point, the primary challenge is the development of a software that cane used to control the robot’s movements, without having to write the raw gcode every time.

License: The text of "Casa Jasmina: Where Arts and Arduinos Meet" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.