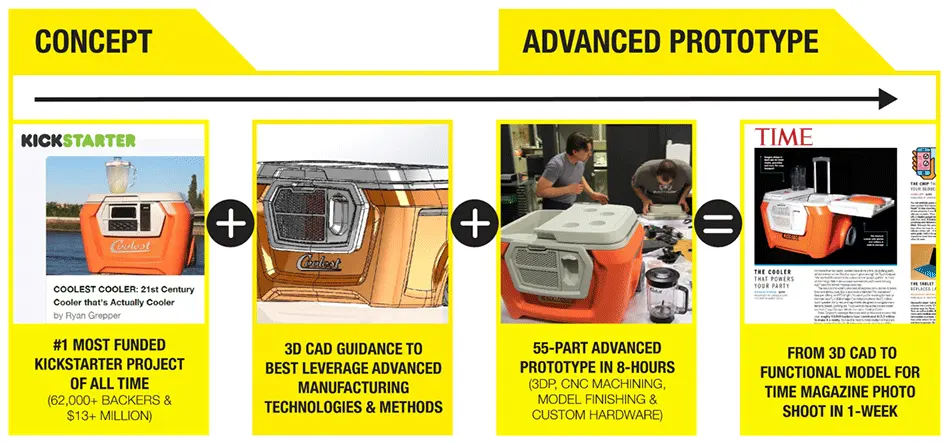

The Coolest Cooler blitzed its prototyping phase by partnering with Studio Fathom to create a 3D printed product in just a few days.

When record-funded Kickstarter project The Coolest Cooler needed a complete prototype done in just a few hours for a TIME Magazine photoshoot, they turned to 3D printing experts Studio Fathom.

The Coolest Cooler concept product raised 26570% of its funding goal on Kickstarter, becoming one of the most successful crowdsourcing campaigns ever in the process. (via Wikipedia)

The overwhelming support attracted interest from the media. When TIME Magazine proposed to do a story with a photoshoot on the Coolest Cooler, it became necessary to turn to rapid prototyping. This is where 3D printing specialist Studio Fathom came into play.

This 21st Century cooler does a lot more than simply cool your beers. It offers an integrated blender for cocktails, a five-inch Bluetooth speaker for music, a compartment light, a bottle opener, and wheels to make it easier to carry around.

Using Stratasys 3D printers, Fathom created 55 individual parts that were assembled to become the Coolest Cooler in just a few days’ time. Taking into account the complexity of the particular product and the level of accuracy required for the various fittings, mounts and gaskets, the feat is impressive.

While Kickstarter offers a platform for ground-breaking ideas to flourish and become reality, it is often the case that projects fail to deliver because of problems faced during the prototyping stage. This is common even for the most over-funded projects, and so the solutions given by 3D printing technologies are crucial, making their involvement almost an absolute prerequisite for the success of any project.

The most important part remains to keep up with the schedule and milestones. This is what keeps the cash flowing in and the project alive, and Studio Fathom has just made it possible. (via studiofathom.com)

License: The text of "The Coolest Cooler Advanced Prototype was 3D Printed" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.