According to US defense contractor Raytheon, 3D printers will soon be used on the frontline to repair and replace missile parts, eliminating supply risks and speeding up research.

At Raytheon’s design site in Tuscon, Arizona, the world’s biggest missile maker, engineers have been working with a 3D printer both day and night. These machines are commercially bought and adapted by Raytheon’s engineers themselves.

Taylor Lawrence, president of Raytheon missile systems said these machines are “over-subscribed” and design engineers are so interested in experimenting with different ways of making missiles that the printers “are fully occupied on weekends and Friday nights.”

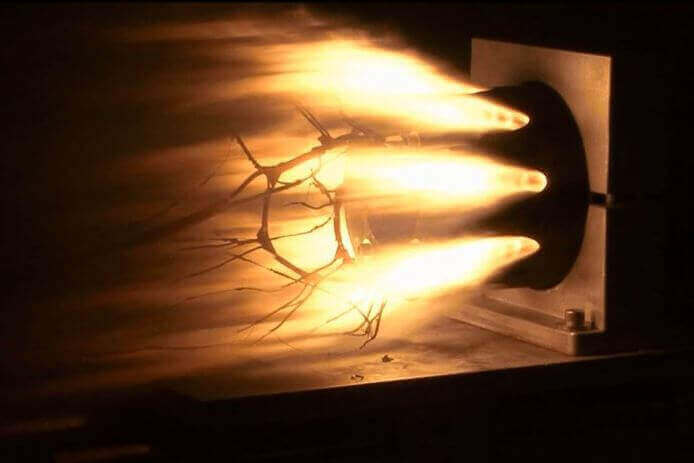

Researchers are working on ways to print the electrical circuits used in guidance systems. Lawrence said: “It will be a while before we print a whole missile, but we definitely see that on the horizon.”

How can 3D Printers Help Missile Production?

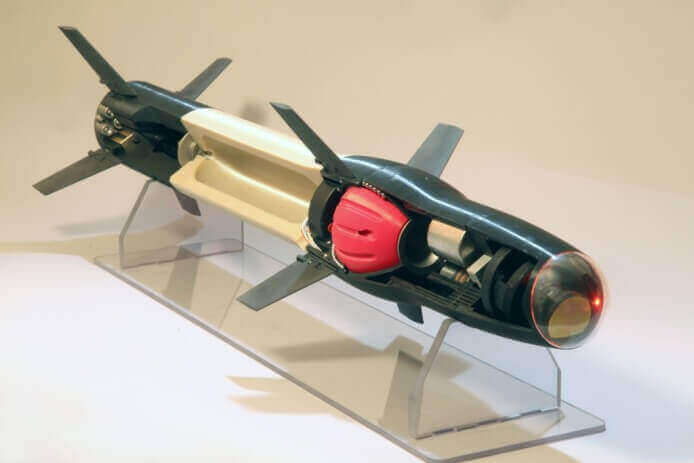

When it comes to defense technologies, 3D printing isn’t a unknown technology. In March 2016, US Navy tested a Lockheed Martin “Trident II D5” missile, which used 3D printed connectors to protect cables.

As we already know, 3D printing can mean that companies can design and manufacture parts in half the normal time. For example, Jeff Morgans, head of operations at MBDA, the European missile maker, estimates that 3D printing could cut missile component production time by up to three-quarters. Next year, they will use a printed part in their Sea Ceptor missile system.

However, Morgans also said: “Performance of weapons is of paramount importance. We have to be confident that the technology without any risk.” Right now it takes more than a year from the day the first component arrives. 3D printing can speed that up significantly. Therefore, the company has, understandably, doubled its investment in 3D printing.

There is also the factor of a rising demand for missiles from governments who want both greater power and precision without a higher cost. Strategic Defence Intelligence, a consultancy, predicts that the global market for missiles and missile defense systems will increase by nearly half, between 2015 and 2025, to $36bn.

At Raytheon, Lawrence said: “We can produce fundamentally new capability more quickly, which ultimately means lower cost.”

3D printing certainly means that enhancements in missiles may also be more feasible too. Lawrence said: “Engineers can come up with brilliant ideas but the production guys say there’s no way. The introduction of 3D printing is allowing us to do that.”

(Source: Financial Times)

License: The text of "Raytheon Research Points to 3D Printing for Missile Manufacturing" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.