MIT researchers make it easy to build robots with a system called Interactive Robogami so you can design, print and assemble in five hours.

If you’re an origami or a robot fan, you’ll be interested to hear about MIT’s new project. Researchers from MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL) are developing the Interactive Robogami system to make robotics more accessible.

Designing a robot with Interactive Robogami can take mere minutes while 3D printing and assembling take just five hours.

The researchers developed the Interactive Robogami system and wrote a paper about it. Adriana Schulz, a Ph.D. student at MIT who co-led the project, explains:

“The goal is to make the process of designing robots accessible… The actuators, the materials, the code, things like that require a lot of knowledge. Our system encapsulates that expert knowledge, so the user can focus on conceptual design… Designing robots usually requires expertise that only mechanical engineers and roboticists have… What’s exciting here is that we’ve created a tool that allows a casual user to design their own robot by giving them this expert knowledge.”

The researchers even made it possible to determine both a robot’s shape and movement in one place. Usually, this is done separately in design systems. In fact, users can play around with 50 different bodies, wheels, legs, “peripherals” and gaits. Then, during designing, the system offers feedback.

3D Print Your Own Origami Robots

The idea is that this system is easy to use while helping you design by analyzing your robot before offering suggestions. Both speed and stability are taken into consideration so you don’t print a robot which immediately topples over.

However, the researchers wanted to test their design on willing participants. They chose a group of eight people to work on two tasks and help the researchers figure out whether the system really was intuitive.

The group was first asked to create a car in ten minutes. The second task saw participants working on a robot to navigate it through an obstacle course as quickly and easily as possible.

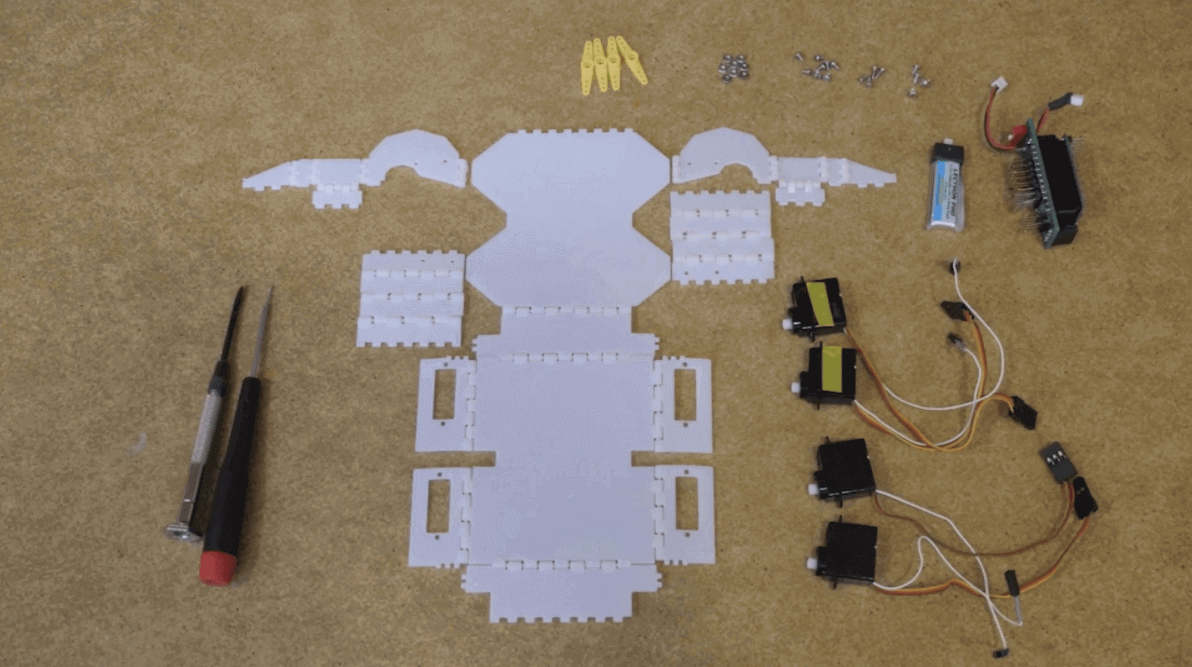

Impressively, it took just 10 to 15 minutes to design a robot. In total, the participants came up with six robots which each took between three and seven hours to 3D print. After printing, the robots each took up to one hour and a half to assemble.

The researchers found that by offering a 3D print-and-fold method, it was possible to reduce printing time by 73 percent. Better yet, they were able to reduce materials used by 70 percent too.

The reason for this is 3D printing 2D parts, essentially as flat faces with joints. Users then assemble the design by folding it and connecting the joints. Cynthia Sung co-led the research. She adds:

“3D printing lets you print complex, rigid structures, while 2D fabrication gives you lightweight but strong structures that can be produced quickly… By 3D-printing 2D patterns, we can leverage these advantages to develop strong, complex designs with lightweight materials.”

Want to find out more? The research paper is to be published in the International Journal of Robotics Research.

Source: RDMag

License: The text of "Design and 3D Print Robots Quickly With MIT’s Robogami System" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.