As 2013 was coming to an end, awareness of 3D printing technologies had exploded, leading people in search of the most complete, versatile, affordable and convenient printer. The harsh reality though, was that a perfect machine capable of printing every material, color and shape simply didn’t exist at the time. Almost exactly one year later, 3D Systems, the first and still one of the largest 3D printer producer in the world, gave everyone an opportunity revisit their consideration for the perfect machine, presenting the new, sensation Projet 4500: a full color plastic 3D printer.

Before the Projet 4500, 3D Systems offered the color printer models in the Projet x60 series. They could (and still can, as they are probably the most common color 3D printer in the world) create objects at high resolutions but the use mainly gypsum based materials that are extremely brittle and therefore usable mostly for static prototypes and statuettes. Another 3D printer, the IRIS by mcor Technologies, uses full color laminated paper but it is slow and the resulting models are still rigid. The other largest 3D printer manufacturer, Stratasys, proposed launched the Objet500 Connex 3, a machine which can 3D print with multiple material and in multiple colors, although they choice is more limited and the price is affordable only to top design studios.

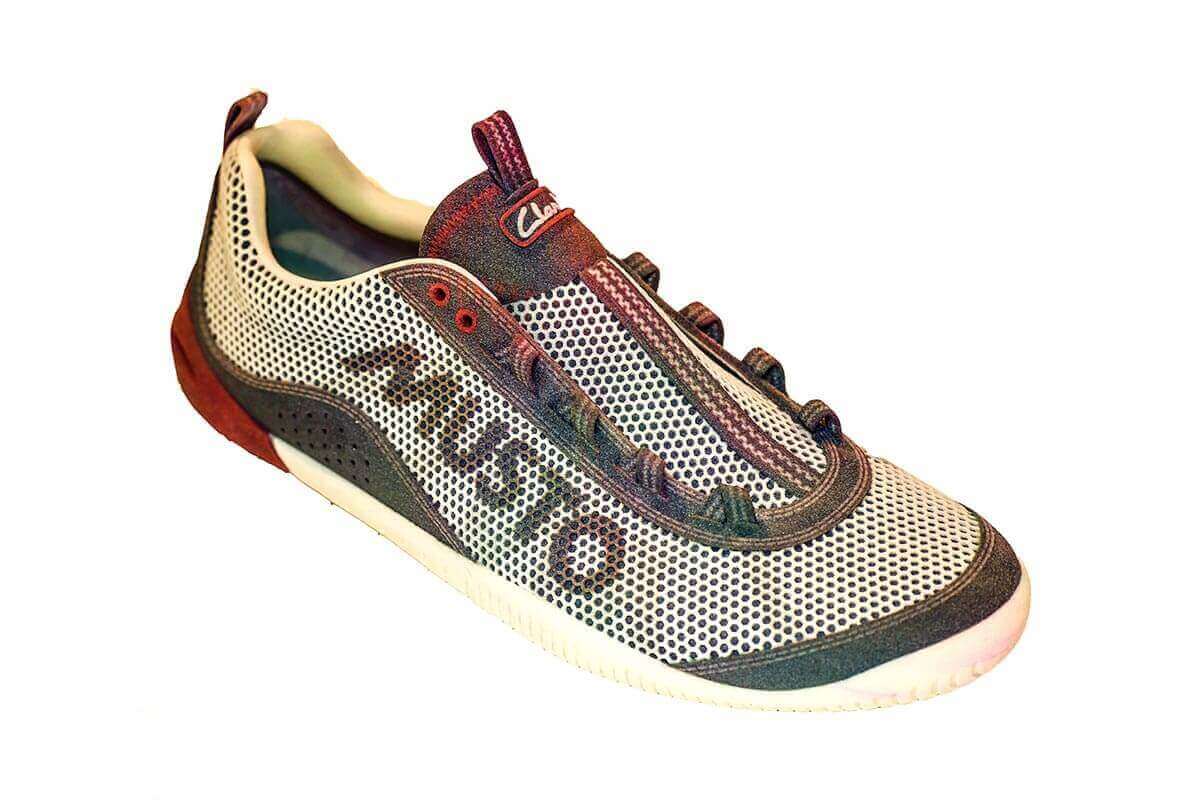

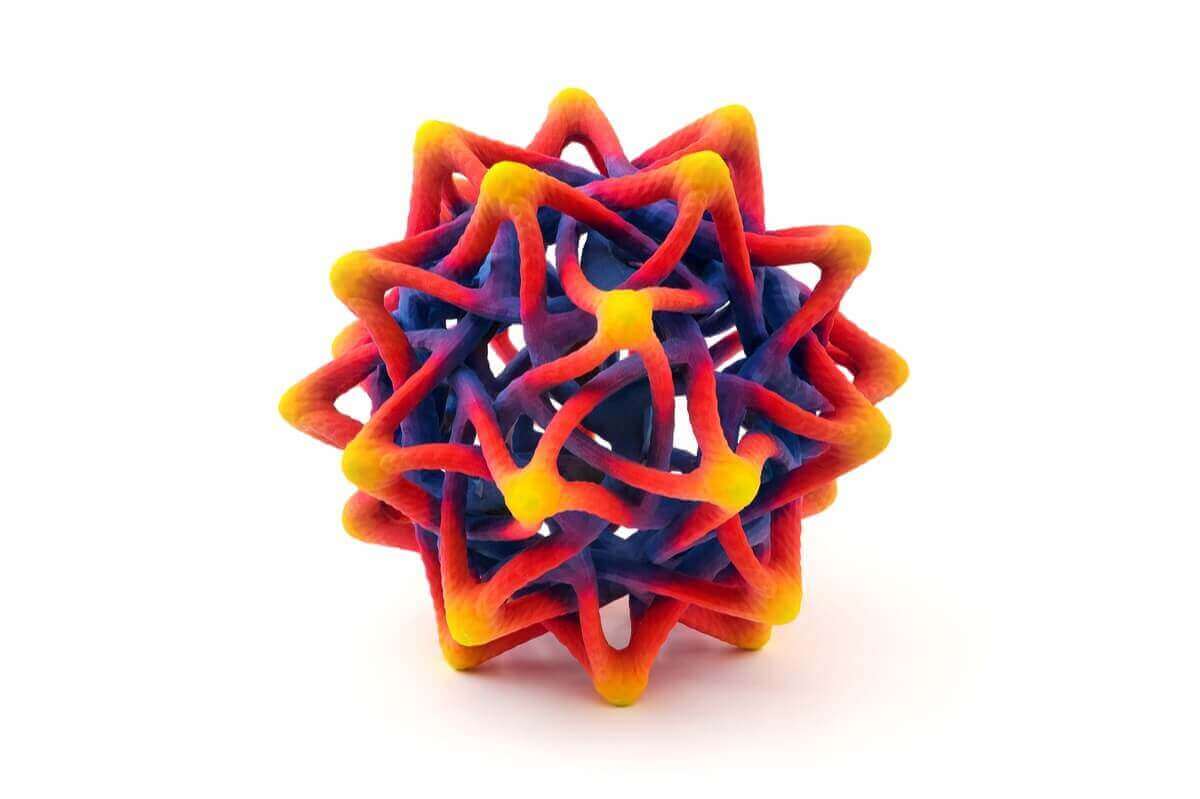

Leveraging on CJP (color jet printing) technology and plastic powders such as the VisiJet C4 Spectrum, the Projet 4500 represents the latest evolutionary step for the 3D colored printing process invented by ZCorporation (or Zcorp) and later acquired by 3D Systems. This printer manages to combine the best characteristics of all these processes, allowing users to create, quickly and easily, objects that are resistant, flexible, durable, functional and colorful. Too good to be true?

Everyone knows how essential color is in order for the 3D printing to reach consumers. The Projet 4500’s advancement is equivalent to the first color movies or first color photo studio, back in the days when pictures were still in black and white. The switch is inevitable and unstoppable: in real life even more than in movies and photos, colors make everything beautiful and more alive, whether it’s an architectural model or an iPhone case.

If you have the nearly 70.000 euro it takes to buy one, printing with Projet 4500 is incredibly simple. The machine will auto-start and automatically perform all checks and calibrations to its mechanical systems. The software provided by 3D Systems is fully compatible with any Windows 7 and Windows Vista PC, and is able to read and correct any OBJ file which, just like the STL format, is used to define 3D printable designs, although OBJ also contains color information. You can also control the printing from tablets and smart-phones using the corresponding Print3D application. In general, the formats that are supported are the STL, VRML, PLY and ZPR (ZPrint) and the machine is able to replicate the colors in Continuous CMY (cyan, magenta, yellow). These are the main mixing inks used in any color printing in order to derive with up to a million colorful combinations.

https://www.youtube.com/watch?v=MFcQ15rSI4Y

Its modern design and aesthetics make it look like an object from the future. Perhaps the only disappointment is its dimensions as the machine size measures at 162x152x80 cm, which, is about five feet in height and width, and has a print area of only 203x254x203 mm that is equivalent to about 10,500 cc. Yet, in this space it is possible to insert up to 18 different models with a diameter of 75 mm. Moreover, one of the most interesting aspects of binder jetting (which is the generic term used to describe technologies based on powder and adhesives, such as this) is that it does not need any supports for the model, since each part is supported by the surrounding non-glued powder.

Just pressing the “start” button will initiate the color jet printing process. A mechanical arm spreads a layer of dust, while at the same time a second mechanical arm moves to release a binder (glue) with very high precision. The layer resolution can reach 100 microns. The color is applied to the outer edge of the layer pixel by pixel with a resolution of 600 x 600 dpi, and the printing plate is lowered to let the arm lie down against the dust. Layer by layer the object quickly takes shape. The particles are held together by the glue and unlike the Projet x60’s plaster-like material, once the object has been completed the material is heated so that the powder particles adhere more to each other, conferring a much superior flexibility to the finished product.

When printing phase is over, the model is placed in the post-processing station which is part of the machine itself and adjacent to the printing process. This way, the dust is not dispersed into the environment and it is possible to recycle larger material quantities: just because the VisiJet C4 Spectrum is not a particularly expensive material, does not mean it should be wasted. With a rate of about one centimeter per hour in height (the “Z axis”), the Projet 4500 is not the fastest machine in the world, but if you manage to place multiple models in the printing table, it can be considered quite effective for small productions.

If you are considering starting a full color 3D printing service, this printer is probably the most suitable machine. To fully take advantage of Projet 4500 though, you will also need a good quality 3D scanner that supports color-detection, like the Artec EVA and Spider. You should also really train your 3D design skills, as you will need to be able to offer some serious added value designs – such as architectural models and industrial prototypes – in order to return of your investment in a relatively short time.

All over the world, on-demand 3D printing and “physical photos” services are on the rise. The main product offer available today consists of statuettes and “mini-me’s”, but tomorrow their use may be extended to everything from a puppy to any family memory and special moments. I until a few months ago it seemed impossible that 3D models could ever become as common as photos, this 3D printes makes it more plausible than ever before.

No matter how colorful and complex the object you imagine is, the Projet 4500 can deliver it. A real “dream factory”.

License: The text of "Projet 4500: Discovering 3D Systems Dream Factory" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.