Delft University of Technology, in the Netherlands, has had an academic paper published recently. It details an exciting new method to effectively 3D print bacteria.

The paper was authored by Benjamin A. E. Lehner, Dominik T. Schmieden and Principle Investigator Anne S. Meyer, all of the university’s Department of Bionanoscience.

It is titled “A Straightforward Approach for 3D Bacterial Printing”, and is rather… straightforward.

Up until now, bacteria has remained a tantalizingly active player in 3D printing. The capability of modifying the properties of 3D printed materials makes it worth pursuing.

Current methods of 3d printing are capable of bioprinting, such as thermal inkjetting, and direct writing. But printing bacteria requires a compromise on the norms of 3D printing to create good enough conditions for the bacteria to thrive. High temperatures and cumbersome pre-building of structures in clean room environments have limited previous efforts.

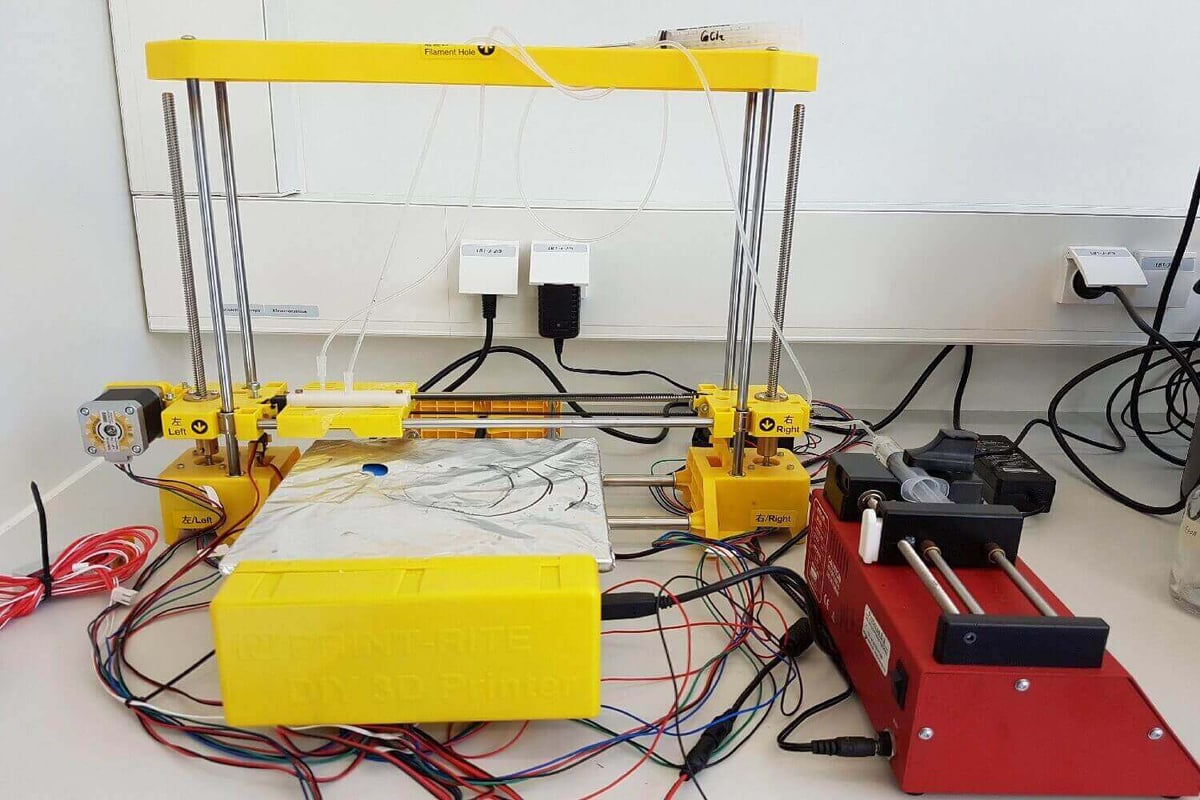

However, Meyer and her team have found that it’s possible to print bacteria to a 1 mm level of detail. They used a custom desktop FDM style machine using syringe pumps to extrude a bioink. Using E. coli as a test case they printed an algae-based gel containing the bacteria onto a bed containing calcium ions. The calcium ions and gel react in such a way that they solidify, creating an aerogel-like structure, laced with bacteria.

The paper details Meyer’s teams’ findings, and is a rather interesting read. You can check it out over at ACS Publications.

But What About Graphene?

Ah yes, the wundermaterial of our time. Carbon fiber has had its day — it’s all about the nano-scale of things now (it hasn’t really — just a little artistic liberty with the writing there).

Simply, graphene is a one-atom thick film of carbon with excellent mechanical strength and electrical conductivity. Great strides are being made researching the potential uses of graphene.

Up until now, it has been possible to create a material closely resembling graphene by reducing graphene oxide, in a process that requires high temperatures and strong chemicals. However, there are bacteria species out there that under the right conditions can effectively reduce graphene oxide.

This means that, using Meyer and her team’s methods you could selectively restructure graphene oxide by printing the bacteria on it. This could create seamless circuitry on the material, making what would otherwise be its own manufacturing process an easy part of a print.

But seeing this happen for real may be some way off still. In its current state the technology is not refined enough for this specific usage, says Meyer.

Source: New Scientist

License: The text of "3D Printed Bacteria May Lead to Custom Graphene Materials" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.