New E3D Titan extruder promises all the benefits of geared extrusion in a lightweight package. The perfect upgrade for the BigBox 3D printer?

DON’T MISS: Read our review of the E3D BigBox 3D Printer

Fresh from their successful Kickstarter campaign for the BigBox 3D Printer, E3D have launched an intriguing new component for 3D printing enthusiasts; the Titan extruder.

With all the power and performance of geared extrusion but in a small and easy to maintain package, this looks like a fantastic little upgrade to the BigBox — and indeed any other 3D printer with an open, hackable framework.

According to the release notes:

“With 3:1 gear reduction, precision milled hobbed gearing and E3D engineering, we’ve developed Titan to push with awesome power, while also being incredibly light and compact. The gear ratio means you’re able to use lighter motors as you’ll need less torque for the same filament pushing force — so direct drive systems have a lighter moving carriage, and bowden-style printers become powerful, reliable little beasts when combined with your E3D V6 hotEnd.”

The E3D Titan is described as a the perfect fit for a modular 3D printing ecosystem, and the team promises that it will work with all configurations of bowden, direct extrusion, or 1.75mm and 3mm filaments. Check out the launch video below:

E3D Titan: “An extruder that is actually pleasant to work with.”

Other benefits touted with the E3D Titan is that it’s “an extruder that is actually pleasant to work with.”

In other words: reliable, consistent, and easy to maintain. Molded with lightweight engineering plastics, the extruder is resilient and has a performance to weight ratio that’s one of the best in its class.

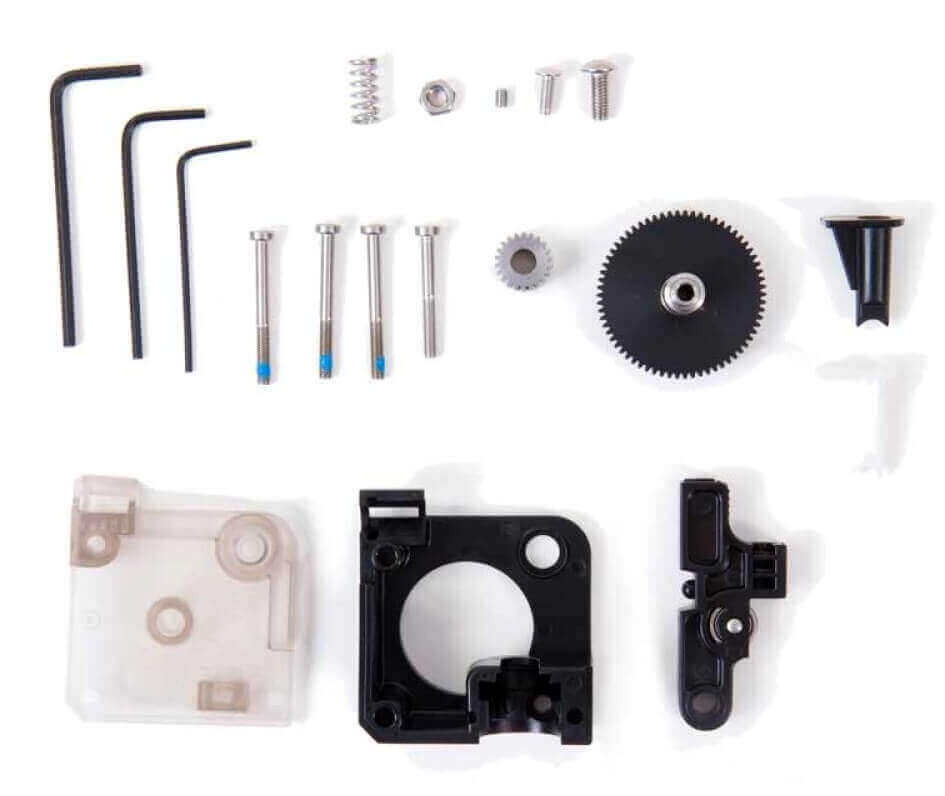

“Titan was designed with a clear intention to make your extrusion sustem *accessible*. The shape of the drive gear teeth ensures that filament flakes off the gear cleanly, and any left over debris can be brushed away with no disassembly, even during printing. The easy-access thumb-wheel makes it easy to manually extrude, purge, load and unload filaments. Titan easily strips down with 1 allen key in 1 minute, everything comes apart and reassembles easily and quickly.”

Excited? We certainly are! Read the full notes on the engineering and design process with the Titan, or visit the store to place an order.

In the meantime, ALL3DP has already been sent a unit for review; we’re in the process of getting the extruder up and running, stay tuned for a future update on our progress.

License: The text of "E3D Titan is a Lightweight & Powerful New Extruder" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.