Imagine a world where you print every tool you need rather than driving to a store or purchasing it online. Wouldn’t it be convenient to access everything you need whenever you need it? That’s what New Zealander Lance Abernethy thought when he designed and printed the world’s smallest drill.

Inspired by Abernathy’s invention, Performance 3-d created another drill that relies on the laws of physics to drill through soft and hard objects. Designing and engineering 3D printer parts is the company’s specialty. It only made sense to design a 3D printed drill.

The “Hand Pump Drills” are unique in their ability to drill holes in objects using a hand pumping motion. There’s no need for electricity or batteries. The drills are powered by force. They drill through wood and even harder surfaces such as aluminum sheet metal.

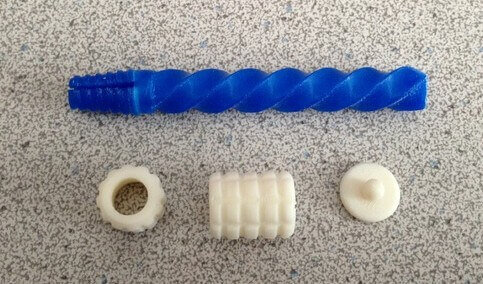

Traditional FFF-based desktop 3D printers print the drill in four pieces. The helix, nut, knurled hand grip, and finger rest take a total of one hour to print. Minutes later, the drill is assembled by hand and ready to use. Portable and cost-effective, it is a solution that potentially changes how companies and consumers build items.

The steps for drilling are as follows:

- Bring the nut back.

- Insert the drill bit.

- Tighten the nut around it.

- Once the drill is tight, place it where you want to make a hole.

- Push downward with one finger on the back end of the drill.

- Move the hand grip up and down with the other hand.

- Admire your work.

Performance 3-d just recently released the CAD files for printing their twist drill. Designer Seng-Poh Lee, also known as Speedy 777, reverse-engineered the drill. His 3D printed plans are free to download through Thingiverse.

A video demonstration of Lee’s drill in use is available at YouTube.

License: The text of "3D Printed Hand Pump Drill" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.