German start-up Floatility has launched a solar-powered electric scooter, developed and prototyped using Stratasys PolyJet and FDM 3D printing technology.

Floatility GmbH is a start-up based in Hamburg, Germany that’s launched an “e-floater” scooter with the potential to redefine urban mobility.

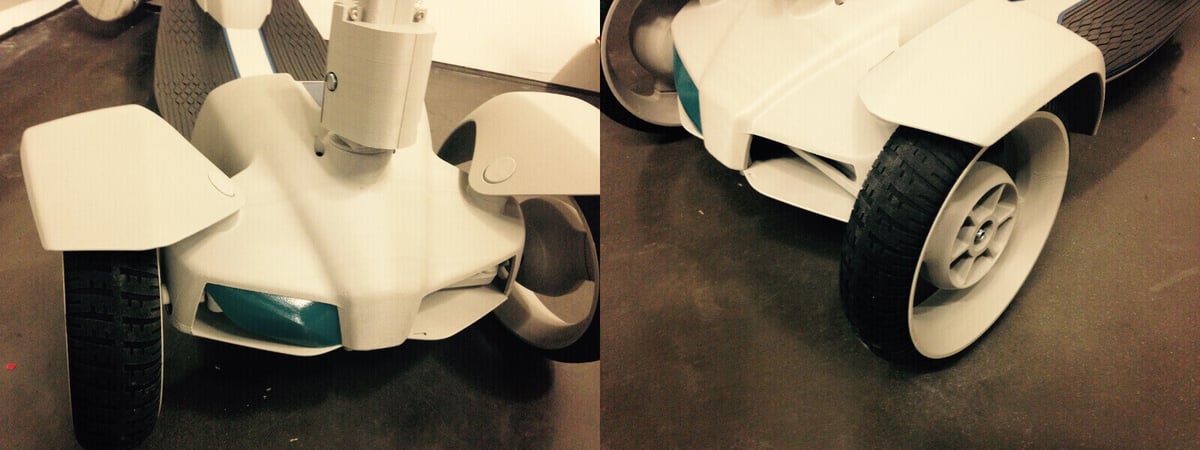

How, exactly? They’ve built their concept around an electric motor, three wheels, and ultralight composite materials, which enables users to stand upright and ride freely without any physical exertion.

If that’s not smart enough for you, the e-floater can also communicate data in real-time to its owner about things like location and battery charge. Oh, and it’s charged by the power of the sun’s rays.

In order meet the product’s official launch in November, Floatility worked with Stratasys and their leading edge 3D printers for the product development cycle to create a working prototype.

An additional benefit was that rapid prototyping achieved cost-savings of 50% over traditional methods. “The need to build prototypes that exactly resembled the final product and that would enable us to test everything thoroughly was vital to the successful launch of this product,” says Oliver Risse, Floatility founder.

”3D printing was essential in this regard as it allowed the team to physically test the design and concept of e-floater as if it were the final product. This not only sped up the product development cycle, but dramatically reduced our product development costs. We would have not been able to take this product from concept to launch without using Stratasys 3D printing solutions to develop a working prototype — it’s as simple as that.”

As well as savings on time and cost, using multiple Stratasys 3D printing technologies also meant that Risse and his team could combine different materials in one print, so that the prototype scooters could be made of both soft and hard materials.

Soft components were the tail- and front lights, wheels and grips, fabricated on the PolyJet-based Objet500 Connex3 Color Multi-material 3D Printer. The tougher components, meanwhile, were FDM 3D printed using the mechanically-strong and UV stable ASA material on the Stratasys Fortus 450 3D Product System.

According to Risse, the lesser alternative would have been to use silicon molding to create the prototype. “This was not ideal for a number of reasons,” he says. “Not only would it have entailed an assembly of up to 20 parts, but the costs would have been significantly higher and the production time would have been double to that achievable with 3D printing.”

Andy Middleton, Stratasys EMEA president, is also pleased with the results.

“The e-floater is a perfect example of how 3D printing enables designers and inventors to turn their concepts into fully-operational products quickly and cost-effectively. In this case, the blend of both our core 3D printing technologies proved instrumental in bringing another exciting and innovative product to market and, as a company, we’re delighted to play a part in helping Floatility – and other start-up businesses like them – bring their ideas to products.”

What do you think about about the Floatility urban scooter concept? Would you ride one to work every day? Let us know in the comments below.

License: The text of "Floatility: Solar-Powered Scooter Prototyped with 3D Printing" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.