The idea of printing buildings and houses is not new. But here’s a fun twist: robot-arms free-form 3D printing your home in open space.

Branch Technology of Chattanooga, Tennessee is letting 3D printers do what they’re good at: complex shapes. Whereas a conventional builder may not be capable of creating millions of tiny patterns, a 3D printer can do just that. “When geometry is not an issue, you can do almost anything,” says Platt Boyd, CEO and founder at Branch (not to mention accomplished architect).

The start-up has raised over $900,000 in seed money and doesn’t seem to slow down. Branch has been busy building demos, and starting a captivating design-your-own-house competition. If you want the chance to see your own dream house become a reality, check it out.

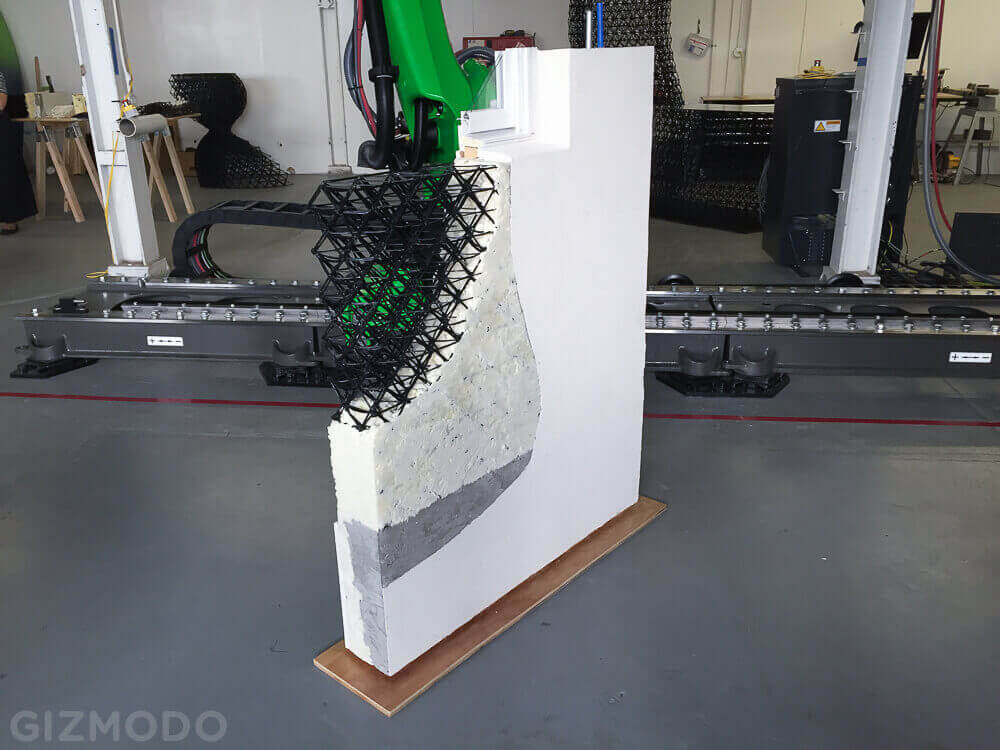

They use a process self-termed “cellular fabrication.” Usually, a 3D printer heats and cools thermoplastics before laying them into a structure. Branch’s free-form printer, instead, solidifies the materials in open space.

Moreover, these walls are able to be constructed in Branch’s lab—or wherever they may set up their printer—and then shipped to builders. Boyd describes their walls as “Lego blocks” that are easily fit together, and finished on site.

“On top of those materials you can add whatever interior or exterior finish you want. Outside could be stucco, or brick. It’s the real deal.”

Touting their endeavor as “democratizing design” the start-up is focused on giving architects unparalleled freedom. While there is, no doubt, plenty of competition around the world, Branch has given people something to daydream about—a creatively designed, free-form printed, Lego-like home of the future. (Via: Gizmodo and Fortune)

License: The text of "Free-Form 3D Printing With Branch Technology" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.