ABB Robotics has replaced traditional production methods with 3D printing to prototype “fingers” for their industrial robot YuMi. Here’s their story.

As a global leader in automation and power technologies, ABB Robotics work on developing industrial robots. These robots can be used for all kinds of applications from electronics to automotive industries.

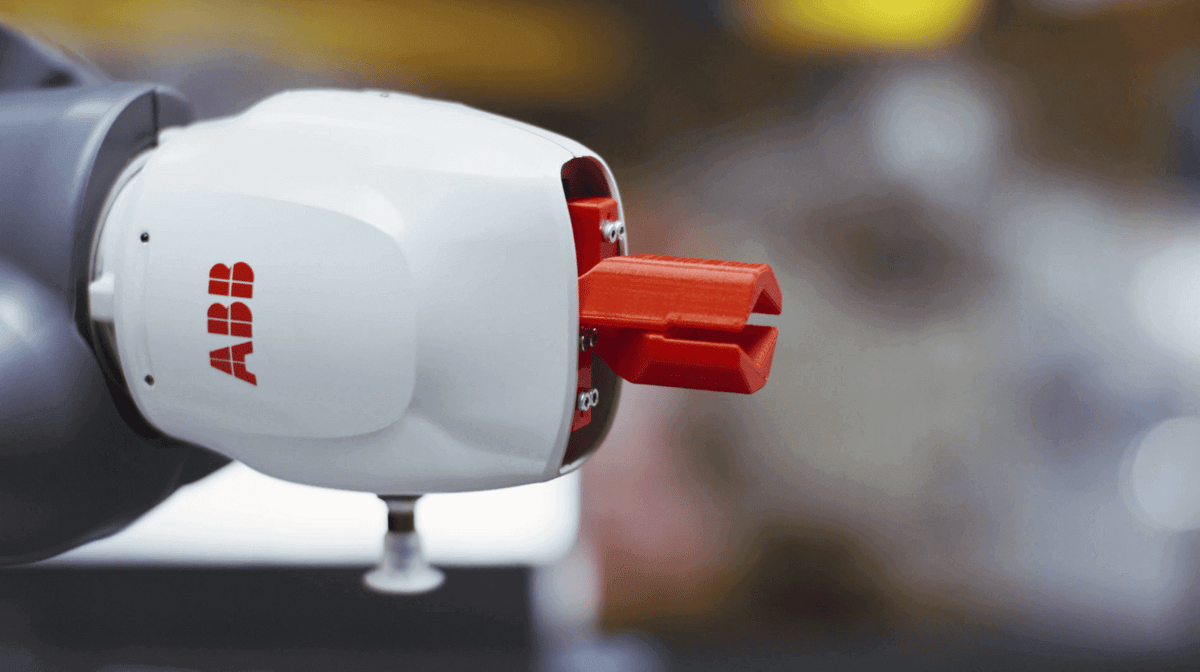

One example is YuMi, a collaborative industrial robot which has been designed to work alongside humans. The robot picks up and places parts for small-part insertions and assembly.

YuMi’s dedication to small parts assembly requires “fingers” in a number of different shapes. This means ABB Robotics has to generate multiple prototypes. Previously, the prototype fingers were developed in-house and external providers were used to manufacture them.

Guillaume Pradels, Relationship Manager for ABB, found that these traditional methods took too much time and money. He began searching for better alternatives and came up with the idea of 3D printing.

3D Printing Cuts Time From Weeks to Hours for ABB Robotics

Originally, YuMi was made with aluminum fingers. If the robot had to handle new tasks, five weeks were needed to get the proper “fingers”. In comparison, 3D printed designs cost almost nothing and took just one hour to create using an Ultimaker 2 Extended+.

Pradels explains in the Ultimaker video above: “When we came to the idea of 3D printing, at the beginning people were skeptical, but I went to a fair, with a 3D model on a USB stick, got it printed and brought it back to ABB. When they saw the results they were very happy and convinced.”

Initially, Pradel’s colleagues were concerned with the replacement of metal. But when they held the plastic results in their hands, Pradel claims they were immediately convinced by the quality.

By fabricating the fingers using a 3D printer, ABB speeds up the whole process from several weeks to just a few days. Guillaume remarks:

“As new designs can now be printed from a desktop without having to pass all the stages of ordering and delivery, we save a lot of time and money. We can do a lot more tests that we wouldn’t be able to do without the 3D printing solution.”

It seems Pradel’s department has started a 3D printing trend. Since using the technology, he reports that others at ABB have begun exploring how printers can help them with their prototyping needs. We wish them good luck.

Source: Ultimaker

License: The text of "ABB Robotics Uses 3D Printing for Functional Prototyping" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.