AlphaPura is an all around multi-purpose 3D printer. It can melt, cut, sinter, weld and solder materials like glass, metal, plastic, concrete and other solid waste. The molten materials are then used as printing raw material to create new products. This deals with some of the most pressing problems of our planet, as re-purposing garbage has beneficial effects in every sense.

While this sounds great, AlphaPura isn’t ready to deliver on the overwhelming expectations. It is currently on Kickstarter trying to raise $10.000 with more than 50 days to go. This means the main product is not ready yet.

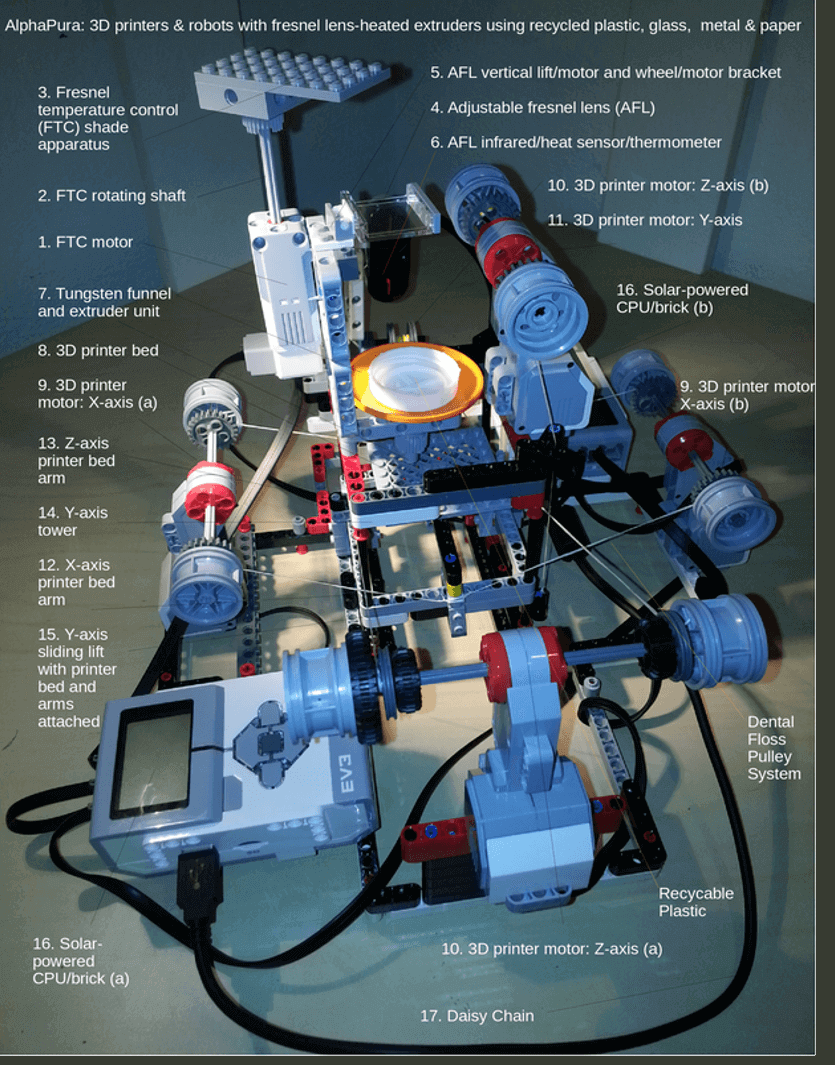

All3DP took a first look at the prototype to see if it’s convincing enough for backers. Creator Frederik Janson used an EV3 Lego robotics kit to build an elaborate prototype composed of more than twenty individual parts that are needed for a plastic waste-melting 3D printer. This first prototype, of course, isn’t melting anything as it is itself made out of plastic, but it serves as a first step.

The second prototype is still on paper, and it is designed to be able to melt and 3D print. The team plans to use tungsten as the main building material for the printer as tungsten is both abundant and has a high melting point. Even the most heat demanding garbage will require 1,650° C to melt, while tungstens melting point stands at 3,315° C.

If the $10.000 goal is reached, the team will start to build a “personal size” AlphaPura with a building area of 5 cm x 5 cm x 7.5 cm. There are aspirations for three larger versions if the funding goes higher. The printer will reach “family size” (7.5 cm x 7.5 cm x 15 cm), community size (30 cm x 30 cm x 30 cm) and finally the industrial size (90 cm x 90 cm x 90 cm).

License: The text of "Garbage Becomes 3D Printing Filament with AlphaPura" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.