Industrial titan GE has bought two European companies for $1.4 billion, both specializing in 3D printing metal parts for jet engines and cars.

General Electric Co has today announced $1.4 billion in European acquisitions, for two companies leading in metal 3D printing technology for manufacturing parts for jet engines and cars.

In a statement, the U.S. company said it had agreed to buy Sweden’s Arcam AB for 5.86 billion kronor ($680 million), together with a separate transaction to acquire SLM Solutions Group AG in Germany. According to Jeff Immelt, Chairman and CEO of GE:

“Additive manufacturing is a key part of GE’s evolution into a digital industrial company. We are creating a more productive world with our innovative world-class machines, materials and software. We are poised to not only benefit from this movement as a customer, but spearhead it as a leading supplier.”

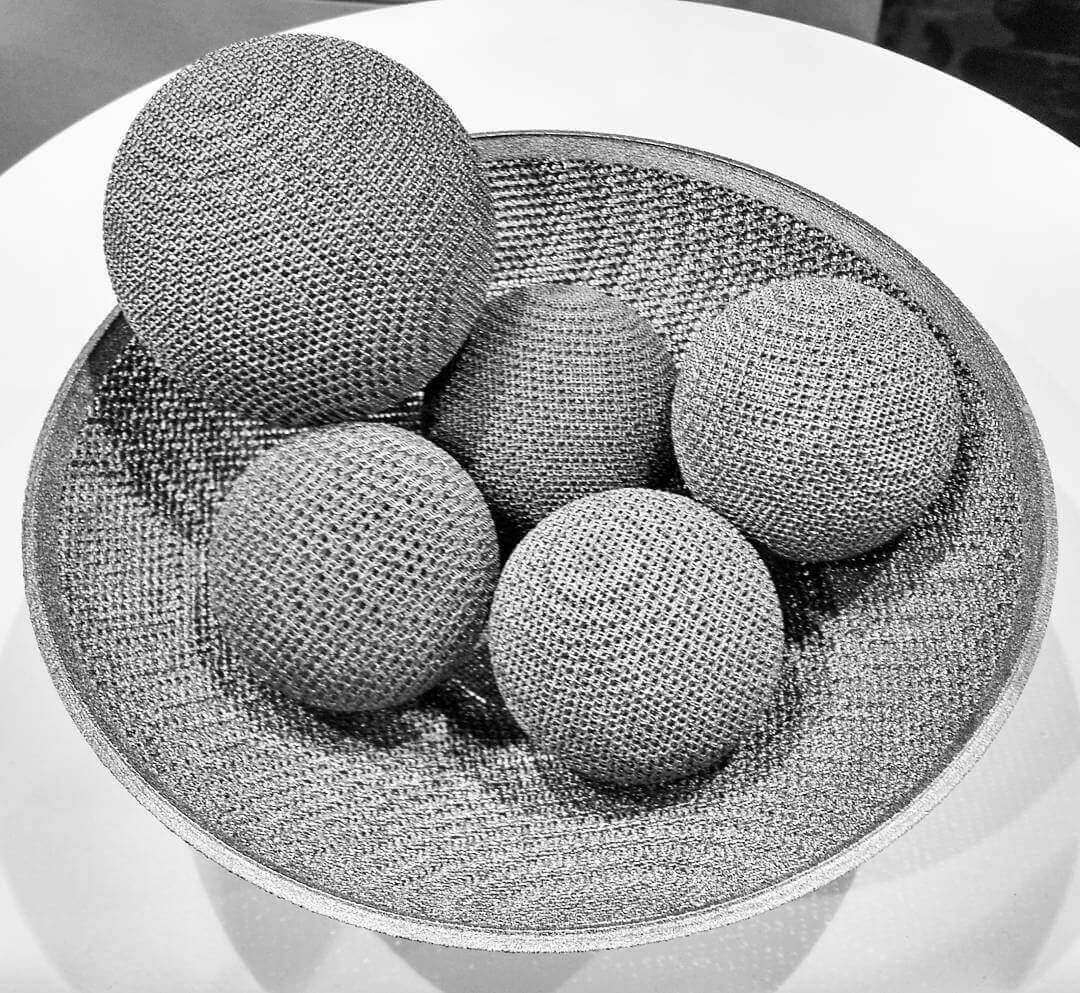

Arcam is a good fit here, with a unique technology that uses electron beams to melt metal powder into firm objects. This is arguably superior in strength and quality to competing laser-based processes. The two companies already had an established relationship; GE was Arcam’s top customer last year, placing their largest order ever to produce turbine blades for jet engines.

But GE is hedging their bets with laser-based processes, too. SLM Solutions produces laser machines for metal-based additive manufacturing, with customers in the aerospace, energy, healthcare, and automotive industries.

Here’s a video of one of GE’s early experiments in 3D printing jet engines:

https://www.youtube.com/watch?v=W6A4-AKICQU

GE is a Strong Believer in Additive Manufacturing

The drive for investment comes from GE’s aviation division, which is looking to print more than 100,000 jet-engine parts by 2020. The company expects to grow the new additive business to $1 billion by 2020; combined the acquired companies generated $142 million in 2015 revenue.

David Joyce, President & CEO of GE Aviation, said in a press release:

“We chose these two companies for a reason. We love the technologies and leadership of Arcam AB and SLM Solutions. They each bring two different, complementary additive technology modalities as individual anchors for a new GE additive equipment business to be plugged into GE’s resources and experience as leading practitioners of additive manufacturing. Over time, we plan to extend the line of additive manufacturing equipment and products.”

The benefits of 3D printing is that additive manufactured components are typically lighter and more durable than traditionally-manufactured parts. This is because they require less welding and machining. And because these parts are essentially built layer by layer, they generate far less scrap material.

Freed of the restraints of traditional manufacturing, GE is confident that additive manufacturing will expand the design possibilities for engineers even further than it already has.

“Additive provides a new palette for engineers to create. Parts are also being designed in GE Power, Oil & Gas, Healthcare and across GE’s services businesses,” continues Joyce. “We see value potential to reduce product cost and improve NPI spend. Ultimately, as we develop more productive machines, we can build additive manufacturing ‘as a service’ for our customers.”

Understandably, the markets reacted favourably to the news. Shares in Arcam surged by 53 percent to 285.50 kronor as of 9:25 a.m. in Stockholm, while SLM jumped 38 percent to 38.42 euros in Frankfurt.

Source: Press Release

License: The text of "GE Invests $1.4 Billion in Metal 3D Printing Jet Engines" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.