Bioprinting is becoming more sophisticated daily. Students from Munich, Germany, hacked an Ultimaker 2+ to 3D print biomaterials even more efficient.

Without a doubt, the yearly iGEM challenge is one of the yearly highlights for students in the field of biology, biochemistry, and biotechnology. The iGEM Foundation is dedicated to education and competition, advancement of synthetic biology, and the development of open community and collaboration. In the field of the 300 finalists, there’s one team which has developed a highly interesting 3d printable bio-ink.

3D printing in medical labs isn’t exactly new, „but the technology has yet failed to progress from basic research to application,“ the team states in their video (see below). This is where they wanted to make a contribution.

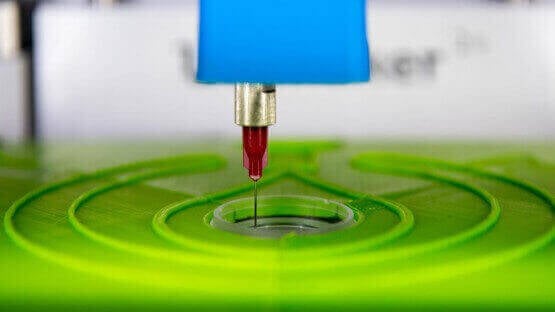

First, the students designed an open-source bioprinting platform based on the Ultimaker 2+ (review here).”We try to print cells, respectively tissue, with a regular 3D printer. For that, we took a conventional plastics 3D printer and modified it to a 3D bioprinter,” says Luisa Krumwiede, team member from TU Muenchen.

All you need for their „biotINK“ modification is the printer itself, some 3D printable mechanical parts and filament. With that, you can build a dish retainer, a modified printhead holding the needle for extraction and a feeding system for the bio-ink.

The Secret is Cell-to-Cell Cross-Linking

Also, they developed a special biological ink to make 3D bioprinting more effective.

So, what’s the benefit of this new bio-ink? If you 3D print tissue, you usually use hydrogel to bind the cells. The gelatinous structures of the hydrogel help the cells to bind together. In this case, things are different. The team developed a bio-ink for their refurbished Ultimaker.

One of the ingredients used is biotin, also known as vitamin B7. Another substance, Streptavidin, works like glue and binds the biotin.

Also, the team altered bacteria and mammal cells, so they developed receptors for biotin. ”All these components should crosslink,” Krumwiede explains. “Streptavidin adheres to the biotin, and the biotin can bind to our receptors. All components should then polymerize and form a 3D structure.”

So, what’s the benefit? The process allows you to print the cells directly onto structures in very thin layers without having to go through the conventional petri dish first. Cells and bio-ink form a mesh of living tissue in the 3D printer.

If you want to dig deeper, here’s the iGEM’s website on this bioprinting project.

(Source: Deutschlandfunk. Images: Andreas Heddergott / TU München)

License: The text of "German Students Develop Improved 3D Printable Bio-Ink" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.